Flaman Rentals Blog

RSS feed

Categories

Recent activity

- What's it like being a Flaman Rental Dealer?

- A Brief History of the Newest Flaman Store in Swift Current

- Disney's NEW Leadership Excellence Training Course

- Disney's Approach To Quality Service

- Disney's Approach To Quality Service

- Trailering 'Rules of the Road' Updated

- 10th Annual Frank J. Flaman Foundation Gala 2016

- Why Frank Cares

Authors

Archive

How a Bench Custom Grain Cleaner More Than Pays for Itself

Posted by Jeff Brown Nov 19, 2024

It’s a scene that’s played out on farm after farm across Canada. Flaman Sales Specialist James Vanbeselaere positions your input and output augers, sets four levelling jacks, flips a switch on the central electric panel, and another farmer is in business.

If you’ve read our other Bench Custom Grain Cleaners Blog, you know that the business of on-farm grain cleaning makes good long-term economic sense. That blog discussed the savings you could bank, potentially over decades. With James’s help, this one details the ease, versatility, and benefits of operating your own personally customized cleaner.

Easy Start Up

“They usually reach us somewhat assembled, so we can pull it out to the customers already set up to go,” James explains. Very little time elapses between when it arrives in your yard and when it starts running - just enough to complete the wiring and the steps outlined above.

Ease of Use

The first goal of customizing a Bench cleaner is customer convenience. The central electric panel gives users quick, easy-to-reach, and unobstructed access to the Variable Frequency Drive (VFD) controls that govern their intake and output auger speeds.

Customers are also likely to admire the convenient method Bench devised for changing screens.

“The A1door latch system is unlike some cleaners that have grader shells you have to unbolt to take off,” James explains. “You wouldn’t have to do that with an Airens screen.” The Bench method is an easy slide-out, slide-back-in process, as James demonstrates in this video.

Dockage doesn’t stand a chance.

“The Bench 54 by 72-inch portable grain cleaner would probably be our most popular unit,” James says. That unit is equipped with components from another manufacturer, Premier Grain Cleaner of Minneapolis-Saint Paul, Minnesota. Like other Bench models, it does just about everything you could ask to winnow out everything but the top-quality grain you want.

Lighter material is immediately vacuumed away by the Cyclo air system pre-aspirator. Vibrating shaker shoes vibrate the scalp deck, grade deck, and sift deck. Each shoe sits above bouncing balls that help move materials to screens where they either fall through to the next layer or are taken off as dockage. That and a final round of Cyclo aspiration effectively removes everything from straw and rocks to fine chaff.

A Team of Machines

There’s even more you can do to deliver pristine commodities, thanks to Bench’s modular extensions. If you’re cleaning barley, you may want to start with a Bench de-bearder to improve your commodity’s flow-ability going into the grain cleaner - and its test weight afterward.

Once you’ve filtered the impurities out of your grain, you can take out the broken kernels using an indent screen. This screen is wrapped around a rotating drum, using centrifugal force to hold kernels of a desired length in the screen’s pockets while smaller kernels fall off the drum and are taken off as dockage. It’s a popular item, for good reason, as James explains.

“There were some grain cleaners we sold in La Crête, Alberta that had just Airens screens with indents because he’s mainly cleaning wheat. They grow a lot of wheat and canola up there.” Indent screens are ideal for longer-grain crops like wheat, which has been the commodity that creates the most demand for grain cleaning, James says.

Portable Possibilities

Wheat may be the crop most customers want to clean, but Bench provides options for a wide spectrum of cereal, oilseed, and pulse crops. Priding itself on versatility as well as portability, Bench offers cleaning equipment designed to handle barley, beans, canola, chickpeas, flax, oats, soybeans and sunflowers.

Flaman also has its own screen distribution facility in Saskatoon. Like Bench, we offer an inventory that’s carefully selected to take excellent care of the crops you put in your bins.

Kind to Your Commodities. Easy on Electricity.

“It’s a gentle feed,” James says of Bench cleaners’ easy-going stability. Those carefully set levelling jacks prevent a great deal of commodity damage by offsetting uneven terrain, but Bench took its smooth, crop-friendly operation an extra step.

“There are eccentrics underneath that provide a counterbalance,” James says, adding mention of another important benefit: “Once the shaker’s moving back and forth, little horsepower is required to move the tray, because of the momentum. So, guys don’t have to worry about having a big enough power supply to run these.”

Like to Know More about Operating Your Own Custom Grain Cleaner?

Flaman Grain Systems experts are ready to show you in-stock Bench Grain Cleaners and answer any questions you have. Call or visit your nearest Flaman location to discuss effective, economical solutions to your farm’s specific requirements.

Posted in Product Information | Tagged with Grain Cleaning | More articles by Jeff Brown

The Benefits of Customized On-Farm Grain Cleaning

Posted by Jeff Brown Nov 19, 2024

"Every farm’s going to be different,” says James Vanbeselaere. “Every area will be different, depending on what they're trying to clean.” As a Flaman Sales Specialist who’s installed and fired up a lot of customized Bench grain cleaners for enterprising customers, he should know.

What he’s showing farmers is a viable alternative to the transport distances, fuel costs, and unloading cues they can see taking their commodities to seed cleaning plants.

Grain Cleaning Comes Home

“You're just paying an expense to have the other guy clean it,” James says. “A lot of custom cleaners charge about a dollar a bushel. We have customers that clean 10 to 20,000 bushels a year. So, they're spending, you know, upwards of 20 or $30,000 just to have their own grain cleaned. So why not keep that money in your own pocket and put it towards your own system? You'll be building an asset out of it."

That’s why Flaman Grain Systems took the next logical step in the evolution of grain cleaning. It forged a partnership with Great Falls, Montana manufacturer Bench Industries to make on-farm grain cleaning a viable option for more producers.

“That relationship was already formed before I started at Flaman,” James says. “So, I guess I’ve just continued it. They fit our needs. We can sell on-farm units in the right sizes for on-farm use.”

Identifying Your Needs. Formulating Your Solutions.

Bench builds their quality grain cleaners to customer specifications, often using farmer-supplied commodity samples as a starting point. They offer a variety of mobile and mini grain cleaners, plus accessories like the popular Airens screens.

“Bench will do a lot of the customization themselves.” James explains. A customer’s specifically recommended combination could start with a portable or modular air screen machine, mini air screen machine, mid-size grain and seed cleaner, or mobile screen machine and include a vital accessory like a debearder/rethrasher, vibratory conveyor, or separator.

Long-Term Reliability

The tens of thousands of dollars farmers can save doing their own grain cleaning every year can multiply over decades. Flaman has a record of choosing grain cleaners based on their potential long-term durability – choices that have often panned out impressively.

“We’ve got a lot of cleaners that have been around for a long time,” James says. “Twenty, thirty, forty years old. They last.”

“VFD” spells power savings and convenience.

Bench custom grain cleaners feature a frequency drive (VFD) that can reduce power consumption by up to 70%. It’s connected to the electrical panel, a single central point of power connection that gives you speed control over your incoming and outgoing augers.

Nationwide Home Grain Cleaning

Wheat farmers are most likely to take up what Flaman and Bench have to offer. There is also demand for cleaning other commodities. Bench equipment can process other cereal crops like oats and barley, as well as oilseed crops like canola, flax, soybeans, and sunflowers, and pulse crops like peas, chickpeas, and beans.

With Flaman operating its own screen distribution facility in Saskatoon, the two-company partnership can help diverse farming operations across the Prairies – and beyond. We try to be coast to coast, all across Canada.” Wherever they go, these units carry their value with them.

Cost Savings, Care, and Convenience

“We’re pretty competitive in the price range,” James says. But he adds the real economic benefit is the money and time farmers can save. “They’re cleaning their own grain, so they’re not paying for it.”

That’s before a slew of design benefits that make grain cleaning a more pleasant process from the moment your unit arrives on your farm. You can read about them here.

James answers two final questions you might already be asking.

What kind of customer does Flaman believe is a good fit for a Bench custom grain cleaner? With the variety of options Bench offers and the spectrum of commodities and working conditions they can handle, there’s only one answer:

“We’re open to everyone.”

So, how do you find out if a Bench custom grain cleaner is right for you?

“Contact your local farm and sales Rep.”

You can do so by calling or visiting your nearest Flaman location. Our grain cleaning experts will be happy to introduce you to the convenience, benefits, and economy of owning your own Bench custom grain cleaning system.

Posted in Product Information | Tagged with Grain Cleaning | More articles by Jeff Brown

Kwik Kleen Grain Separators. More than Dockage Removal.

Posted by Jeff Brown Oct 07, 2024

When you’re trying to take off a crop in a limited amount of time, there are some things you just don’t want in your bin or your transport truck. Dockage and small seeds from weeds like Kochia or volunteer canola can compromise the condition of your harvest while costing you extra time and money. But there’s something you can do about it.

Removing small seeds will increase airflow, which will speed up your drying time and reduce your risk of heating. Taking out chaff, thin kernels, and other forms of dockage will increase your bushel weight and quality, lowering your transport costs.

Kwik Kleen's high-capacity five-auger 572 and seven-auger 772 grain separators handle these tasks quickly and efficiently. They also help with farming techniques that maximize your land’s productivity.

They remove what you don’t want. The Kwik Kleen system is ideal for separating large and small materials, earning it a reputation for superior dockage removal. It’s designed to separate light product with advanced features for tasks like sizing barley and taking thins out of cereals. This will increase your bushel weight, and lower transport costs, because you’re carrying only the grain you want to ship and nothing else.

They’re made for intercropping. Planting two compatible crops in the same ground at the same time can yield several nutritional benefits. When the time comes to separate them, a Kwik Kleen is well suited to separating large and small commodities like barley and canola, chickpeas and flax, and peas and canola. They’re also helpful if you’re sorting out biproducts for other uses, like dockage for livestock feed.

Cost-effective, high-capacity, and efficient Kwik Kleen grain cleaners excel at dockage separation but can be easily adjusted to perform multiple grain separating tasks.

There’s much more to the Kwik Kleen. Mitch from Flaman walks you through the electrical or hydraulic drive option, available auger sizes, and the variety of screen options available. For more information, call or visit your nearest Flaman location.

Posted in Product Information | Tagged with Kwik Kleen Grain Cleaning | More articles by Jeff Brown

Be ready for harvest 2022: Summer is the time to build your bins & install your grain handling equipment

Posted by Calla Simpson Jun 24, 2022

Now that seeding is complete and the crops are growing, you may be starting to think about the next steps in your farming operation for 2022. This likely includes thoughts of additional Grain Storage, Grain Handling, and even Grain Drying equipment.

It may seem early to plan for harvest, but summer is a great time to build your bins and install your grain handling equipment to move the crop come harvest time. Buying now will ensure your equipment is installed and ready to go in the fall – so you can have peace of mind all season long.

Lean on the Pros

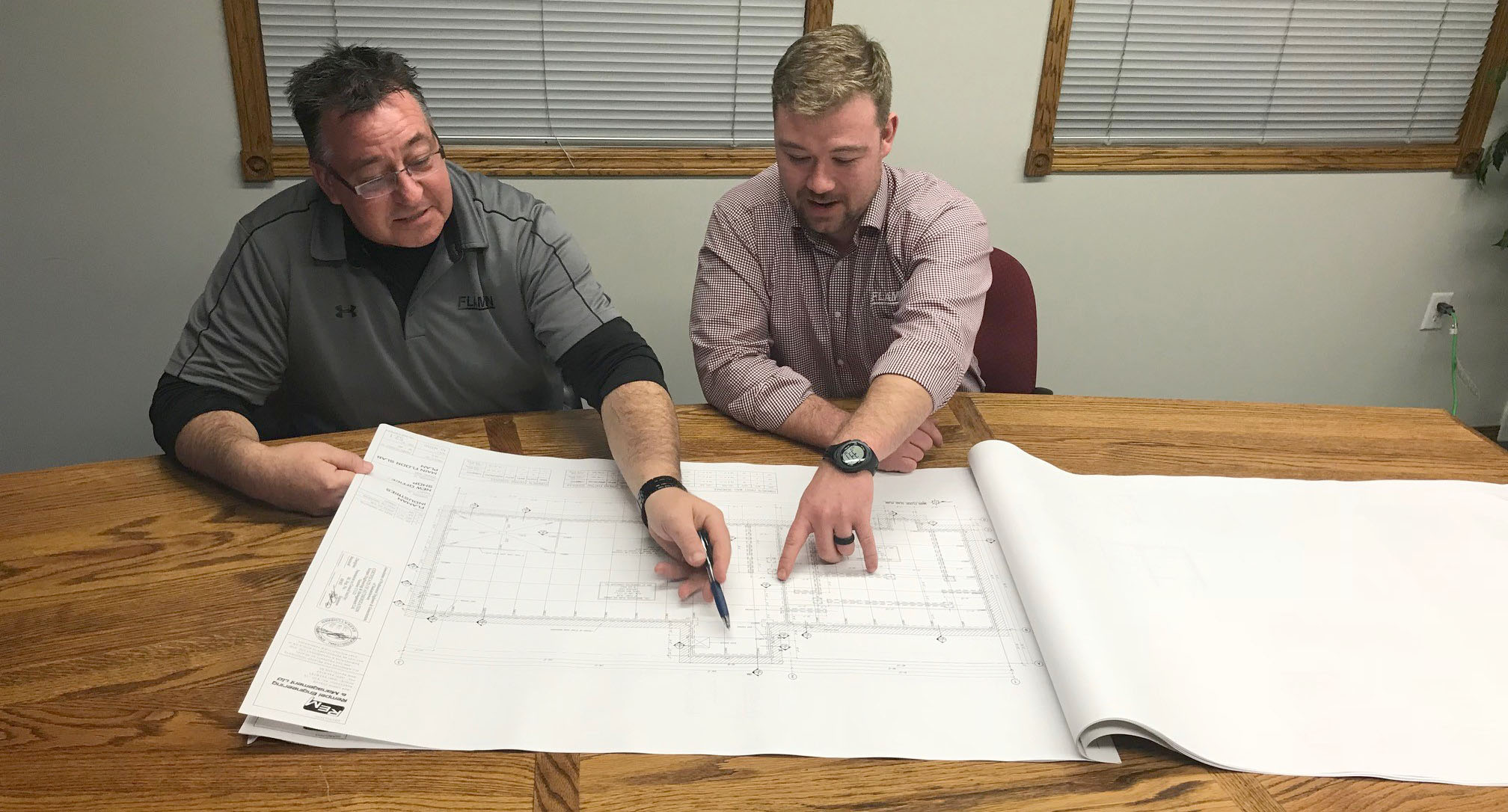

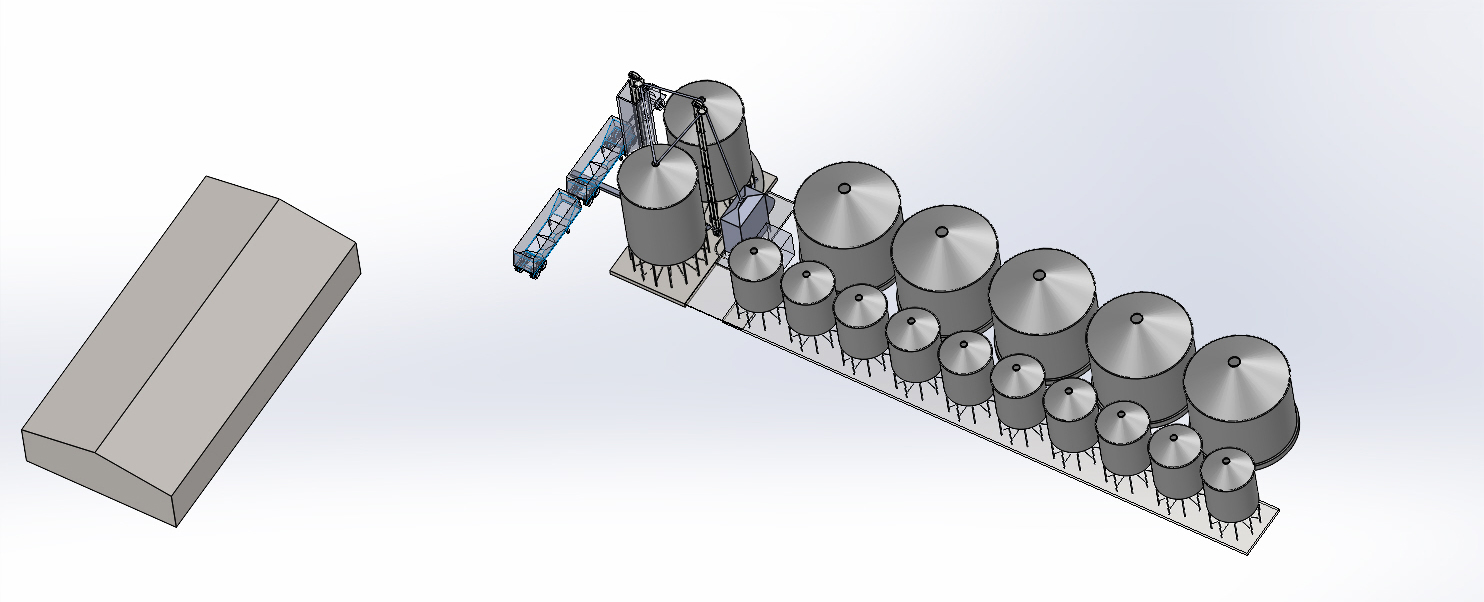

At Flaman, our Grain Systems team is equipped to work with you on developing your yard for the future. Let one of our industry experts come to your yard to measure, draw, and discuss your needs for the coming year. Our tactical approach provides you with various drawings and site layouts that can utilize your existing equipment, and plan for future expansion in a multi-phased strategy.

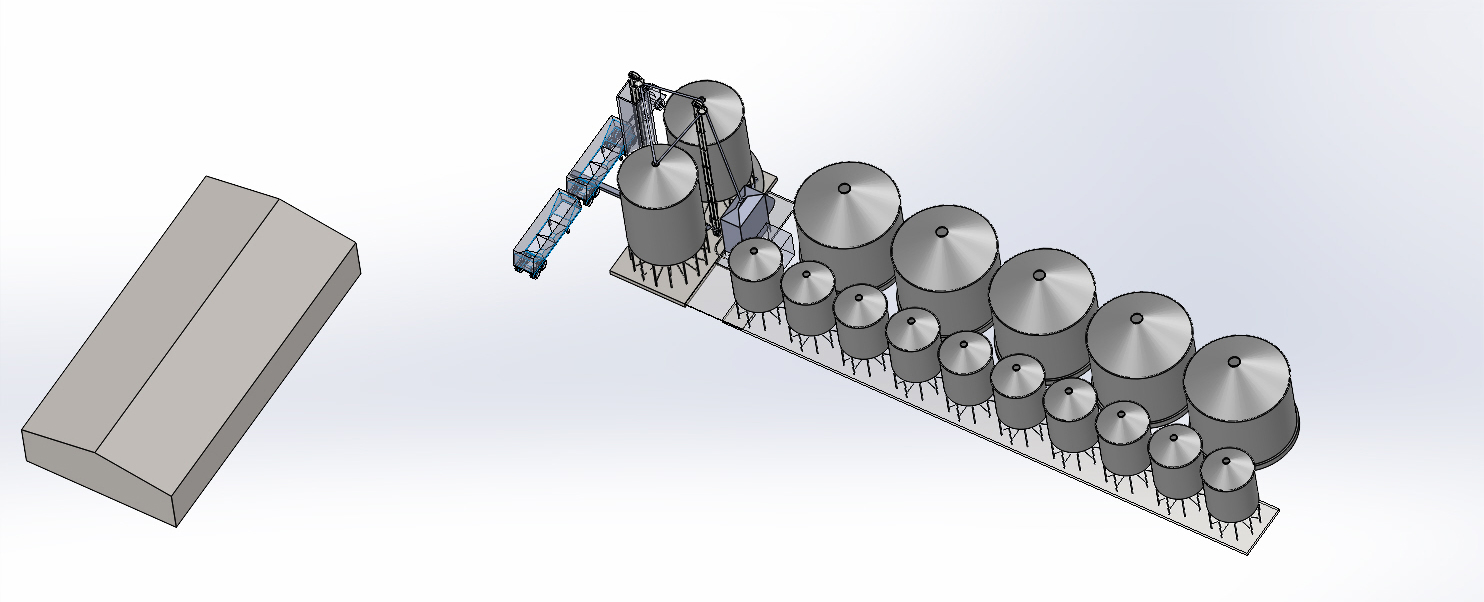

We can create a yard design based on your operational needs and the desired function of your site.

We specialize in full grain handling setups, including a wide range of bucket elevators and pneumatic conveyors – such as the Walinga Ultra-Veyor. Our turn-key offering also includes grain dryer systems, like the NECO Mixed Flow Dryer, as well as grain cleaning and processing facilities, automated bin sites, and producer loading sites.

Our team is here to guide the entire setup and installation process of your grain handling system and provide maintenance and service for every item that goes in and out of our doors.

Schedule your appointment today for a free, no commitment site assessment.

-----

For more information on our grain handling and grain drying solutions, talk to one of our agriculture specialists at your nearest Flaman location.

Posted in Ag news | Tagged with grain systems grain handling grain drying grain cleaning turnkey bin site NECO Walinga | More articles by Calla Simpson

Why You Should Choose Flaman for Your Next Custom Screen Project

Posted by Calla Simpson Mar 18, 2022

Flaman Grain Systems is Western Canada’s largest custom screen manufacturer.

Not only do we stock over 50 varieties of material for any type of screen you may need, but we also have a team with over 50 years of combined experience in the Grain Systems industry.

From large terminals to small plants, we ship custom screen orders anywhere in North America – but especially throughout the prairies.

Inventory

One of the advantages of working with Flaman for your custom grain cleaning screens is our extensive inventory. We have 54 different types of screen materials in stock and on the shelf, as well as the frames to go with them.

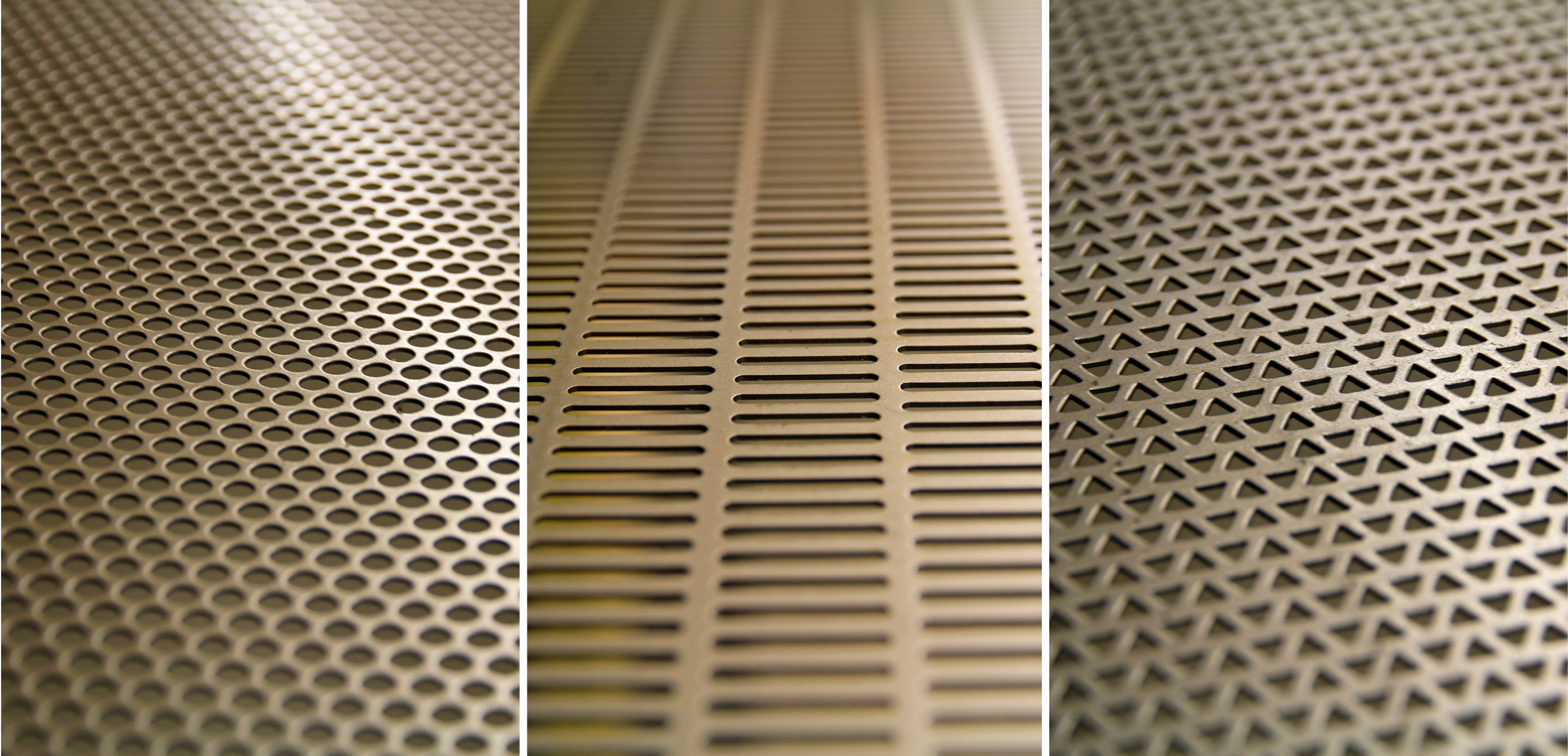

Round Hole, Slotted, and Triangular Screen Options

Round Hole, Slotted, and Triangular Screen Options

We have screens available for almost any make or model cleaner, as well as custom-built to your specifications. We offer round hole, slotted, triangular, wire mesh, and specialty perforating screens, with either wooden or aluminum frames.

Grader Shells

Grader Shells

We also carry grader shells, scalper reels, indent shells, and ball racks, along with a full supply of durable hand screens and sieves in a variety of materials and sizes. Specialty order hand screens are also available.

Hand Screens & Sieves

Hand Screens & Sieves

We begin by assessing your needs from technology to capacity, so we can accurately match you to the proper equipment for your grain cleaning operation. After we find the right machine for your farm or commercial operation, we work with you to determine the correct size and type of screen.

We hand screen grain samples for size and quality, so we can provide you with an accurate recommendation of screen sizes. Then we decide between wood or aluminum frames, wire meshes, or specialty orders, as well as any other accessories or add-ons.

All of our screens are manufactured in-house out of our Grain Systems shop in Saskatoon, Saskatchewan.

Experience

When it comes to our screen division, it is our people that really make the difference. From sales and operations to carpentry and welding, our team has long-term experience in the Grain Systems industry.

With over 20 years of experience with Flaman, Roy prides himself on getting the right equipment in front of his customers. Roy’s extensive grain cleaning knowledge and his passion for helping find solutions for his customers is the foundation of the Grain Systems team.

“My favourite part of working with this team is the people. We have a lot of fun here, too.”

Roy, Shop Manager & Grain Systems Analyst

Roy, Shop Manager & Grain Systems Analyst

With a smile, Mike keeps the sales and operations side organized and running smoothly in a busy atmosphere.

Mike, Grain Systems Sales

Mike, Grain Systems Sales

Our screen manufacturers are integral to the shop and the Grain Systems team. They are consistent, hard-working, and skilled woodworking and metal manufacturers. Gerwin has been with the company for over 12 years, and Wency has been part of the team for 10 years.

Wency, Screen Manufacturer

Both Gerwin and Wency are motivated by family and take great pride in their work. Their happy attitudes and humour make all the difference in making the workplace a positive environment.

Gerwin, Screen Manufacturer

From Start to Finish

At Flaman Grain Systems, we believe in supporting you from start to finish – from screen manufacturing and operations, right up to processing plants and turn-key grain system installations. This includes supplying, installing, and servicing various grain cleaners, bucket elevator systems, and other grain handling equipment.

copy.jpg)

With our unmatched inventory and long-term experience, Flaman is a great choice for your next custom screen project.

When you buy from us you are not just buying a product, you are gaining the ongoing support of a team with over 50 years of experience.

-----

If you have any questions about screen manufacturing, or any of our on-farm or commercial grain cleaners, grain dryers, or grain handling equipment, contact us or visit your nearest Flaman location.

Posted in Division News | Tagged with grain systems grain cleaning grain cleaners screen manufacturing perforated screens custom screens processing plants | More articles by Calla Simpson

From start to finish, the Flaman Grain Systems team is right beside you

Posted by Mitch Flaman Apr 07, 2021

At Flaman, we understand that investing in your farming operation and expanding your yard site is important for continued growth and efficiency. That’s why we believe in supporting you from start to finish.

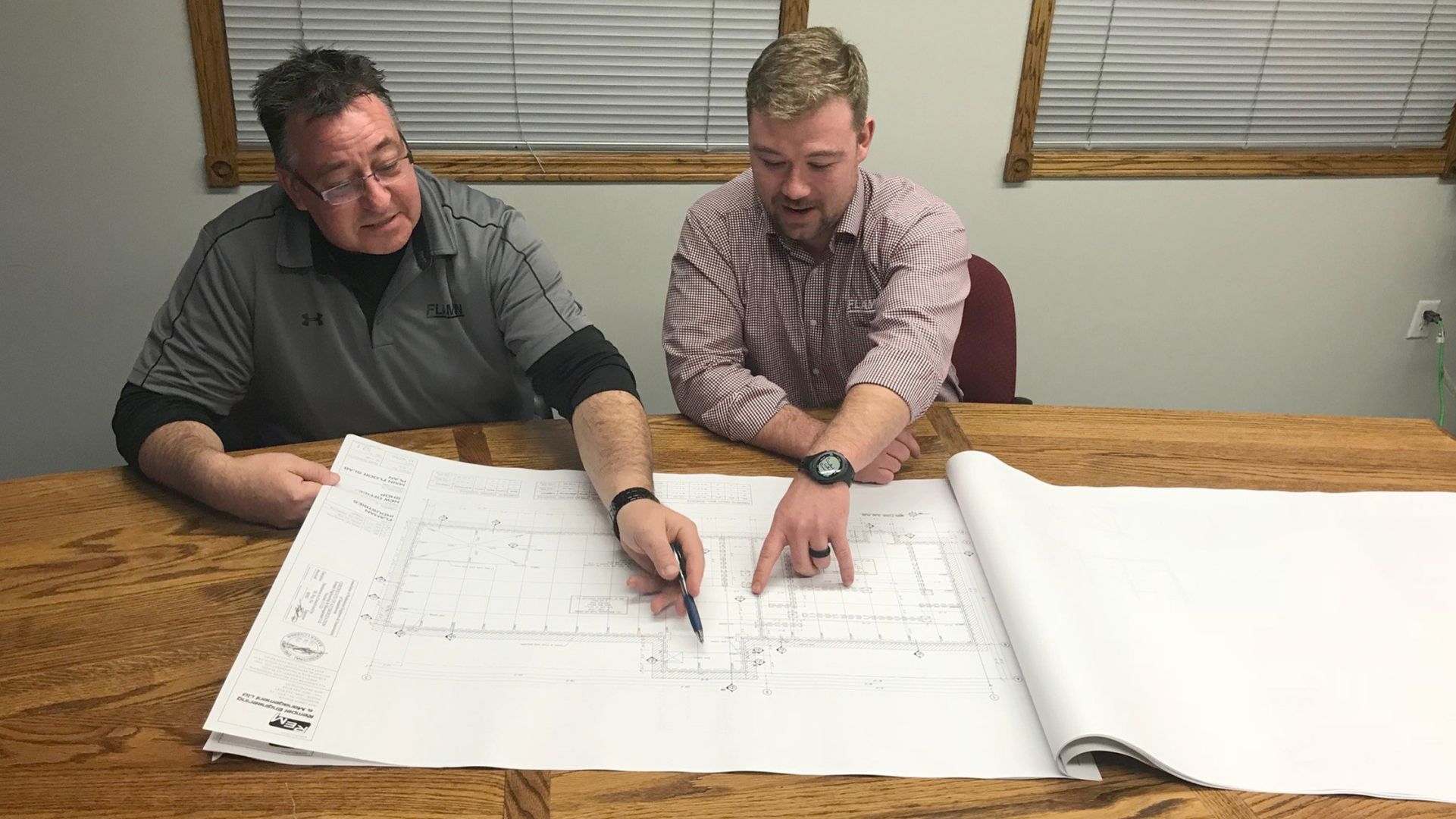

Customers share their experiences working with the Flaman team for their drying & handling setups (above)

Our Grain Systems team are experts in grain handling, grain drying, and grain cleaning. When you buy from us you are not just buying a product, you are gaining the ongoing support of a team with over 50 years of experience.

From Start to Finish

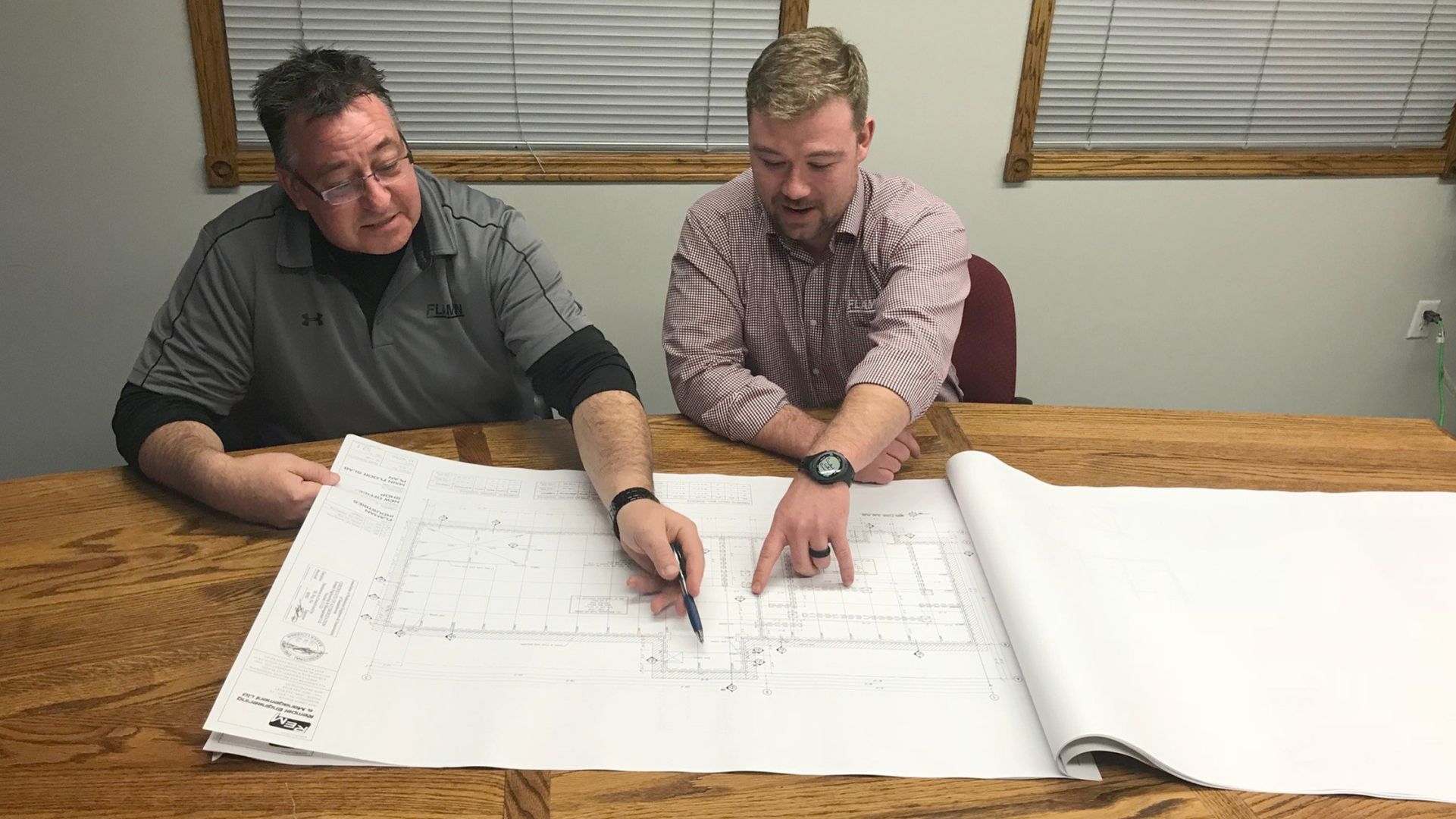

One of our industry experts will sit down with you to discuss and understand what your needs are for the coming year, as well as any future plans you may have. From there we will design a phased approach, with future expansion in mind.

We provide complete engineered drawings constructed in-house, with multiple alternatives to come up with a solution that works for your operation.

Once the equipment is decided on, we will continue to work with you through the site preparation and construction. Our job is not done until your equipment is handling grain the way you expect it to. And even then, we don’t consider our job to be done. Rather, we shift our focus to make sure you remain satisfied with the performance of your equipment.

That’s where our Service Team comes in. This dedicated team of certified technicians specializes in after sales support including warranty, pre-season and post-season maintenance, optimization, and commissioning of your machines to ensure your equipment is always running at peak performance.

Our Service Team Lead explains what you can expect from our team even after the sale (above)

We also offer access to a customer service hotline with live tech support after hours (in season only).

When you buy from us you are not just buying the equipment, you are buying the total solution. We have been here for over 60 years and we look forward to continuing to grow with you as your farming operation grows.

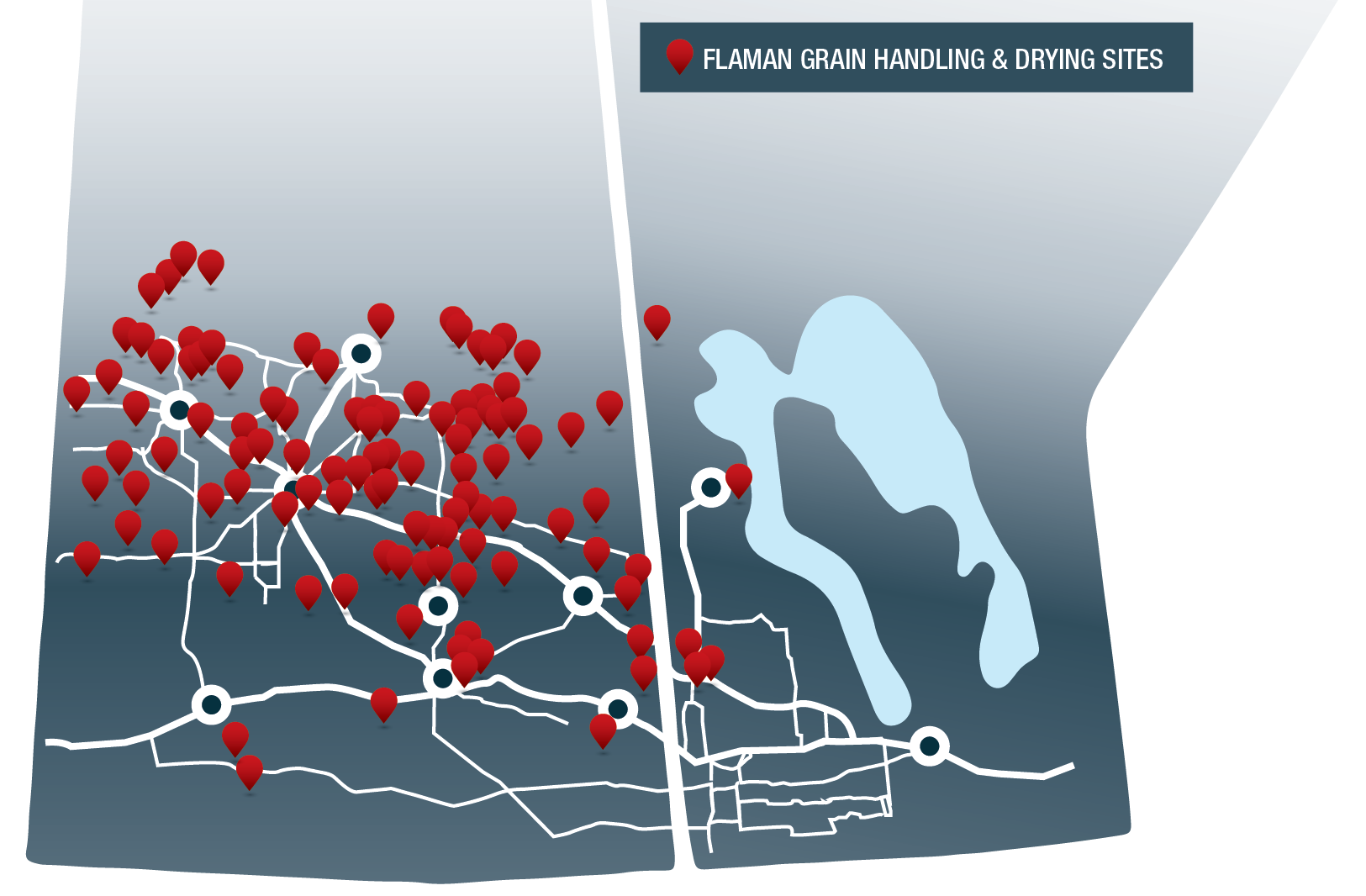

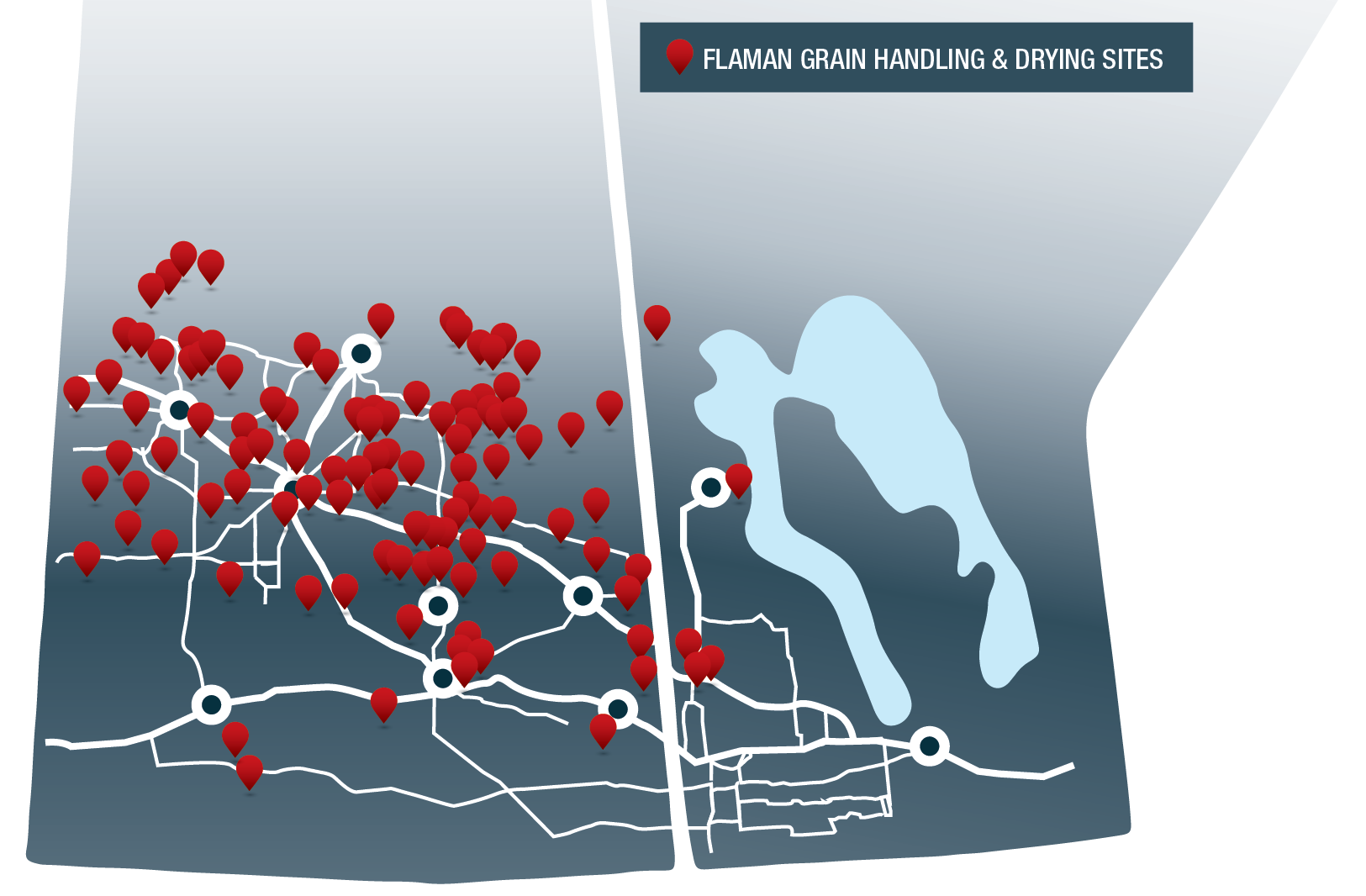

Map of Flaman Grain Handling and Drying sites throughout Saskatchewan & Manitoba (2021)

-----

If you are considering adding grain handling, drying, or cleaning equipment to your farm, give us a call or talk to one our Grain Systems specialists at your nearest Flaman location.

Posted in Division News | Tagged with grain systems grain handling grain drying grain cleaning optimization site drawings yard planning | More articles by Mitch Flaman

From start to finish, the Flaman Grain Systems team is right beside you

Posted by Mitch Flaman Apr 07, 2021

At Flaman, we understand that investing in your farming operation and expanding your yard site is important for continued growth and efficiency. That’s why we believe in supporting you from start to finish.

Customers share their experiences working with the Flaman team for their drying & handling setups

Our Grain Systems team are experts in grain handling, grain drying, and grain cleaning. When you buy from us you are not just buying a product, you are gaining the ongoing support of a team with over 50 years of experience.

From Start to Finish

One of our industry experts will sit down with you to discuss and understand what your needs are for the coming year, as well as any future plans you may have. From there we will design a phased approach, with future expansion in mind.

We provide complete engineered drawings constructed in-house, with multiple alternatives to come up with a solution that works for your operation.

Once the equipment is decided on, we will continue to work with you through the site preparation and construction. Our job is not done until your equipment is handling grain the way you expect it to. And even then, we don’t consider our job to be done. Rather, we shift our focus to make sure you remain satisfied with the performance of your equipment.

That’s where our Service Team comes in. This dedicated team of certified technicians specializes in after-sales support including warranty, pre-season and post-season maintenance, optimization, and commissioning of your machines to ensure your equipment is always running at peak performance.

Our Service Team Lead explains what you can expect from our team even after the sale

We also offer access to a customer service hotline with live tech support after hours (in season only).

When you buy from us you are not just buying the equipment, you are buying the total solution. We have been here for over 60 years and we look forward to continuing to grow with you as your farming operation grows.

Map of Flaman Grain Handling and Drying sites throughout Saskatchewan & Manitoba (2021)

-----

If you are considering adding grain handling, drying, or cleaning equipment to your farm, give us a call or talk to one our Grain Systems specialists at your nearest Flaman location.

Posted in Division News | Tagged with grain systems grain handling grain drying grain cleaning optimization site drawings yard planning | More articles by Mitch Flaman

Be ready for harvest 2020: Summer is the time to build your bins & install your grain handling equipment

Posted by Calla Simpson May 29, 2020

As seeding is coming to a close throughout the province, you may be starting to think about the next steps in your farming operation for 2020. This likely includes thoughts of additional Grain Storage, Grain Handling, and even Grain Drying equipment.

It may seem early to plan for harvest, but summer is a great time to build your bins and install your grain handling equipment to move the crop come harvest time. Buying now will ensure your equipment is installed and ready to go in the fall – so you can have peace of mind all season long.

Lean on the Pros

At Flaman, our Grain Systems team is equipped to work with you on developing your yard for the future. Let one of our industry experts come to your yard to measure, draw, and discuss your needs for the coming year. Our tactical approach provides you with various drawings and site layouts that can utilize your existing equipment, and plan for future expansion in a multi-phased strategy.

Our Specialists can create a yard design based on your operational needs and the desired function of your site.

Our Specialists can create a yard design based on your operational needs and the desired function of your site.

We specialize in full grain handling setups, including a wide range of bucket elevators and pneumatic conveyors – such as the Walinga Ultra-Veyor. Our turn-key offering also includes grain dryer systems, like the NECO Mixed Flow Dryer, as well as grain cleaning and processing facilities, automated bin sites, and producer loading sites. Our team is here to guide the entire setup and installation process of your grain handling system and provide maintenance and service for every item that goes in and out of our doors.

Schedule your appointment today for a free, no commitment site assessment.

-----

For more information on our grain handling and grain drying solutions, talk to one of our agriculture specialists at your nearest Flaman location.

Posted in Ag news | Tagged with grain systems grain handling grain drying grain cleaning turnkey bin site NECO Walinga | More articles by Calla Simpson

The secret behind cleaning grain with indent cylinder machines

Posted by Roy Ritchie Aug 22, 2012

The indent cylinder machine is designed primarily to separate grain by kernel length. It separates long kernels from shorter ones. The cylinder itself is a thin-walled tube with indents formed on the inside to the shape of a hemisphere. These indents are known as pockets.

By using indent pocket size, the kernels that fit into the pocket are lifted up and dropped into a trough that runs the entire length of the cylinder, while the longer kernels slide off and tail out the end. Indent pocket sizes are measured in 64ths of an inch similar to screen sizes used on screen machines. These cylinders are case hardened to give them a longer life span. Cylinders not hardened would wear out very quickly.

The cylinder always lifts up the shorter product that fits into the pocket and always tails off longer kernel; shorter from longer! A smaller pocket like a #13 will lift small weeds like buckwheat while tailing out wheat, while a larger pocket like a # 20 will lift wheat and tail out wild oats. Using combinations of different indent pocket sizes can do very fine separations of these products.

Indents use a combination of pocket size, centrifugal force, friction and gravity to make separations possible. By using different pocket sizes, particles of a certain size are able to be lifted off. The speed that the cylinder turns creates friction and centrifugal force that hold the particle in place. As the cylinder turns, that particle is lifted to a point where gravity takes over and allows the kernel to fall into a collection trough.

Speed of the cylinder is critical: too fast and the kernel is carried too far; too slow and gravity drops the product before reaching the collection trough. Usually indent speeds are between 42 and 58 RPM. One or two RPMs can make a huge difference in separation and capacity.

The receiving trough catches and carries the lifted kernel to the end of the machine and discharges them into a spout. This trough is adjustable in order to make the cut or separation at the exact point of the particle size variation desired. The separation of the products usually happens between 60 and 45 degrees ahead of top dead centre.

Due to the fact that various seeds have different moisture, surface conditions, and specific gravity it is important to be able to hold the cylinder at a constant speed. Any fluctuations in speed will affect the actual trough adjustment and therefore the separations.

While feed flow and constant cylinder speed are critical, the unit is no better than the person running it. If you take time to understand the operation of the unit and allow a reasonable time after making adjustments you will find that the indent cylinder, regardless of make will do a good job for you. It will do this with minimal attention and service for a long period of time.

We at Flaman have several models and makes of indents available for sale. We are here to help.

This is one man’s opinion...

Posted in Product Information | Tagged with grain cleaning indent cylinder grain kernel Flaman grain sorting | More articles by Roy Ritchie

Operation of a Air Screen Grain Cleaner

Posted by Roy Ritchie Jan 27, 2012

Operation of an Air and Screen

As the name implies, air screen machines use a combination of suction air that is drawn through the curtain of grain as it falls from the hopper onto a series of screens. The screens then size the product by width of the kernel, and a final air suction process is used.

With an air screen, the grain is fed onto the screens by either a vibrating feed system or by using a metered feed roll. In either case a feed gate controls the flow and an even flow is given to the machine. Making sure there is an even flow is critical to the quality of the job to be done.

As the grain falls from the feed system onto the screens, there is a process by which air is drawn through the curtain of grain. By doing so, light grain, chaff and dirt are drawn off the product before the grain touches the screens. The air mixed with dirt etc. is drawn into an expansion chamber where the chaff etc. separate and the heavy material is augured out. This process is the first thing that happens and it is also the last process as the grain leaves the machine. Increasing or decreasing the air volume allows the operator to decide how much product he wishes to remove.

Screens size the kernels by width. A system of screens removes any product that is wider than the kernel chosen [scalping], or narrower than the product chosen [sifting]. Screens are generally measured in 64ths of an inch, For example a 5.5 round would be a sifting screen for flax and would be 5 and ½ 64ths of an inch in diameter.

There are several types of screens available in perforated steel. Round hole, slotted hole, and triangular hole are the ones generally used for grain cleaning. There are also a variety of wire mesh screens available for special use. The type of grain dictates the type of screen.

We at Flaman have over 100 years of combined experience in screens, over 55 sizes of screen material in stock, and are dedicated to offering our customers top notch service.

This is one man’s point of view…

Posted in Product Information | Tagged with Grain Cleaning and Handling air screen grain cleaner sieve sift scalf | More articles by Roy Ritchie

What is Ergot?

Posted by Roy Ritchie Dec 12, 2011

Ergot is a type of fungus that grows on many grasses, rye, wheat, barley, and triticale.It infects the floret of the grass or cereal and mimics the process of pollinated grain growing on the plant. On ergot infected plants, a spore destroys the ovary, and then connects to the plant by attaching itself to the plant’s seed nutrition system. An infected floret can also infect other florets by insect dispersal of the asexual spores. That means that an insect can carry millions of the spores to other plants in the region. When mature ergot drops to the ground the fungus remains dormant until proper conditions trigger its fruiting phase, germinate and re-infest an area.

Ergot is toxic. Infestations in the grain can cause spontaneous abortions in people and animals, as well as some very unpleasant symptoms. It can cause irrational behavior, seizures, convulsions, unconsciousness, even death. This explains why there is almost zero tolerance for ergot in grain for sale. Much of the grain should not even be fed to animals. Point zero one [.01%] percent is all that is allowed for a #1 specification.

Ergot has infected a wide area in Saskatchewan and Alberta over the last few years. Some places have had the infestation 3 or more years in a row with various areas having ergot at 0.7% and higher. It is getting worse. My personal belief is that it is here to stay. Some years will be better than others but it will always be a market factor. Plant scientists don’t even have a straight answer to this problem. There is a wide difference of opinion. Maybe a prolonged dry spell will reduce the amount but as soon as it rains at the right time again we are back to ergot woes.

This is only one man’s opinion…

Next installment, how do we proceed? Colour Sorters vs. Gravity Tables.

Posted in Product Information | Tagged with Grain Cleaning and Handling Colour Sorter Ergot | More articles by Roy Ritchie

Locations

Locations

.JPG)