Flaman Rentals Blog

RSS feed

Categories

Recent activity

- What's it like being a Flaman Rental Dealer?

- A Brief History of the Newest Flaman Store in Swift Current

- Disney's NEW Leadership Excellence Training Course

- Disney's Approach To Quality Service

- Disney's Approach To Quality Service

- Trailering 'Rules of the Road' Updated

- 10th Annual Frank J. Flaman Foundation Gala 2016

- Why Frank Cares

Authors

Archive

Be ready for harvest 2022: Summer is the time to build your bins & install your grain handling equipment

Posted by Calla Simpson Jun 24, 2022

Now that seeding is complete and the crops are growing, you may be starting to think about the next steps in your farming operation for 2022. This likely includes thoughts of additional Grain Storage, Grain Handling, and even Grain Drying equipment.

It may seem early to plan for harvest, but summer is a great time to build your bins and install your grain handling equipment to move the crop come harvest time. Buying now will ensure your equipment is installed and ready to go in the fall – so you can have peace of mind all season long.

Lean on the Pros

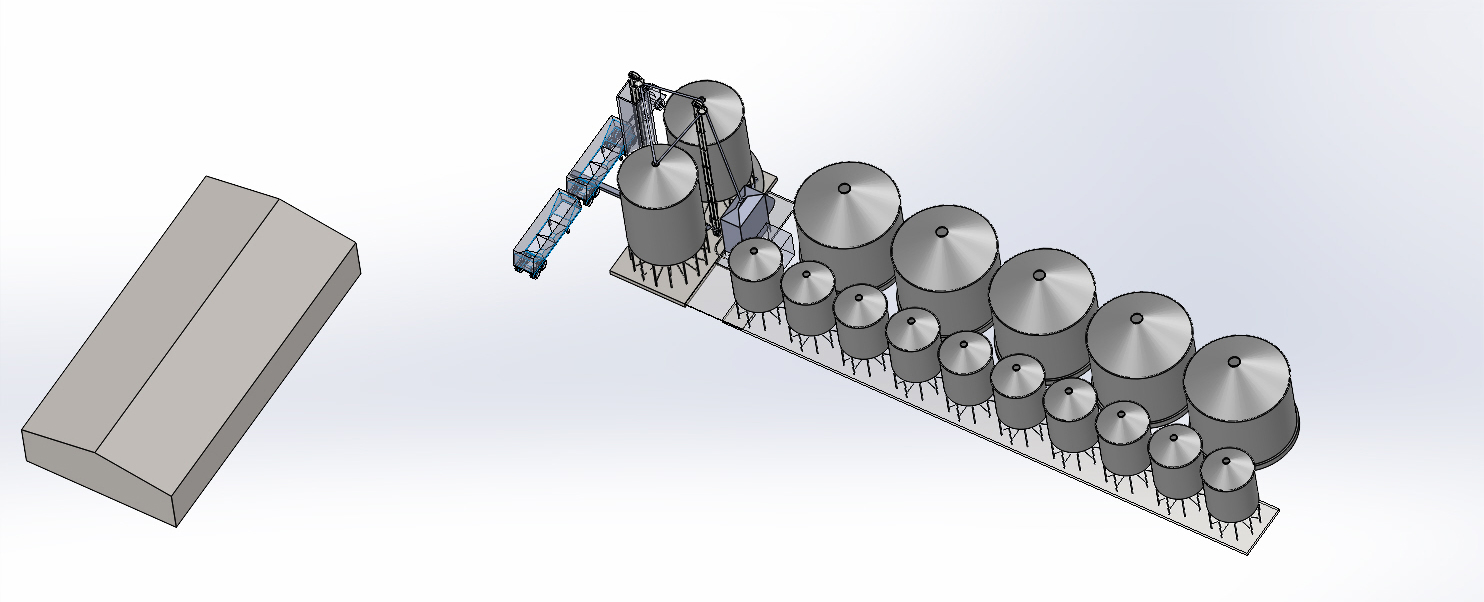

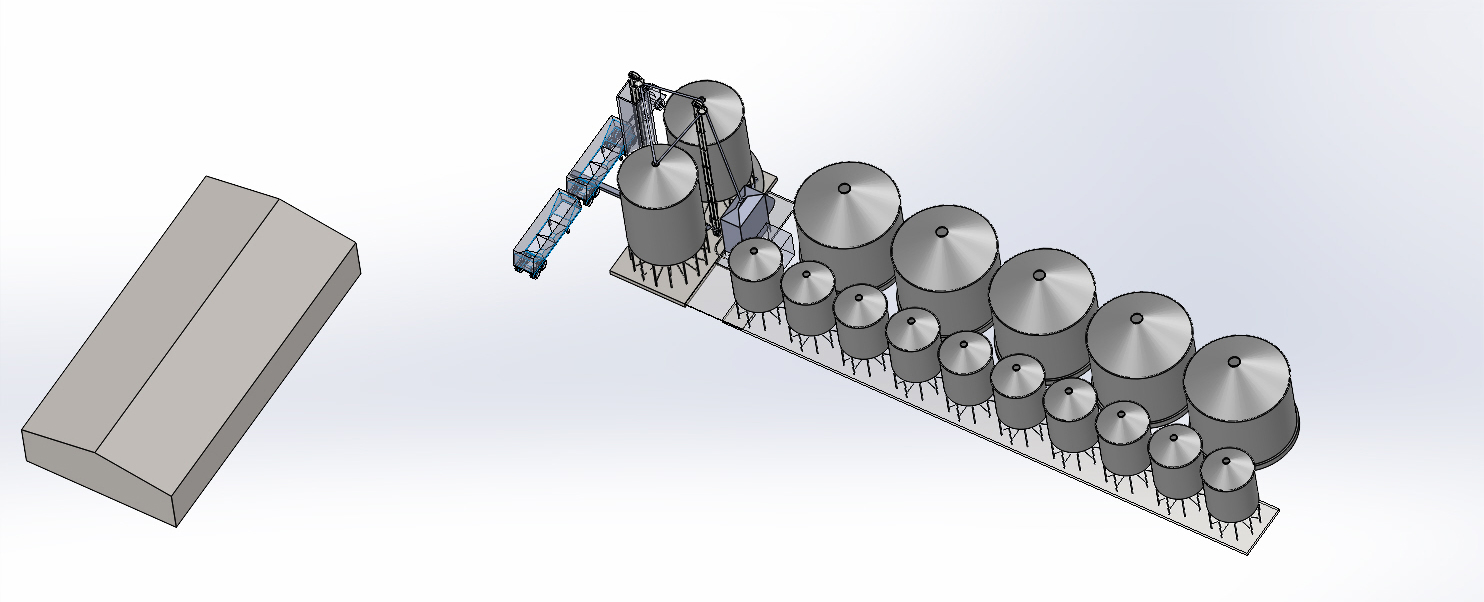

At Flaman, our Grain Systems team is equipped to work with you on developing your yard for the future. Let one of our industry experts come to your yard to measure, draw, and discuss your needs for the coming year. Our tactical approach provides you with various drawings and site layouts that can utilize your existing equipment, and plan for future expansion in a multi-phased strategy.

We can create a yard design based on your operational needs and the desired function of your site.

We specialize in full grain handling setups, including a wide range of bucket elevators and pneumatic conveyors – such as the Walinga Ultra-Veyor. Our turn-key offering also includes grain dryer systems, like the NECO Mixed Flow Dryer, as well as grain cleaning and processing facilities, automated bin sites, and producer loading sites.

Our team is here to guide the entire setup and installation process of your grain handling system and provide maintenance and service for every item that goes in and out of our doors.

Schedule your appointment today for a free, no commitment site assessment.

-----

For more information on our grain handling and grain drying solutions, talk to one of our agriculture specialists at your nearest Flaman location.

Posted in Ag news | Tagged with grain systems grain handling grain drying grain cleaning turnkey bin site NECO Walinga | More articles by Calla Simpson

Why You Should Choose Flaman for Your Next Custom Screen Project

Posted by Calla Simpson Mar 18, 2022

Flaman Grain Systems is Western Canada’s largest custom screen manufacturer.

Not only do we stock over 50 varieties of material for any type of screen you may need, but we also have a team with over 50 years of combined experience in the Grain Systems industry.

From large terminals to small plants, we ship custom screen orders anywhere in North America – but especially throughout the prairies.

Inventory

One of the advantages of working with Flaman for your custom grain cleaning screens is our extensive inventory. We have 54 different types of screen materials in stock and on the shelf, as well as the frames to go with them.

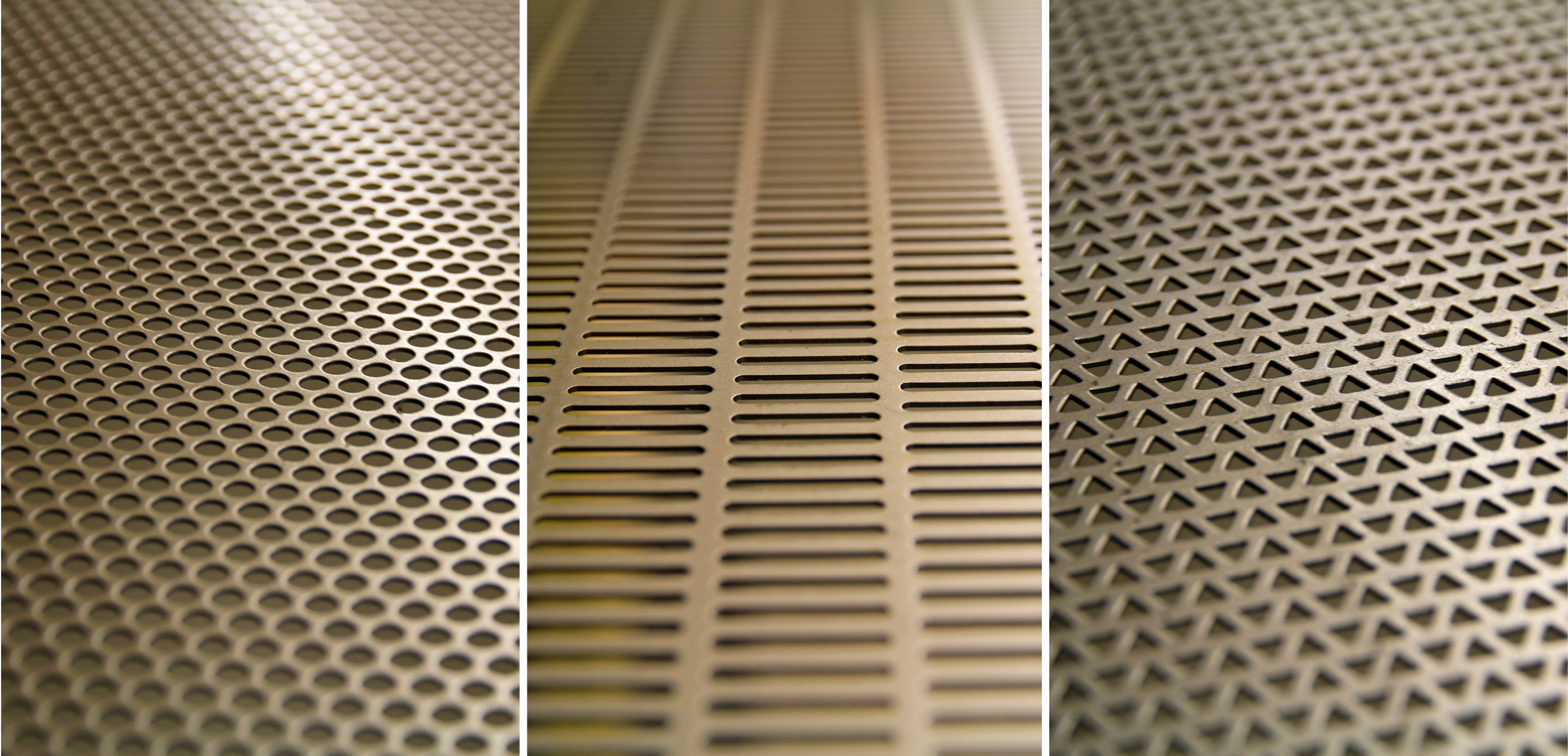

Round Hole, Slotted, and Triangular Screen Options

Round Hole, Slotted, and Triangular Screen Options

We have screens available for almost any make or model cleaner, as well as custom-built to your specifications. We offer round hole, slotted, triangular, wire mesh, and specialty perforating screens, with either wooden or aluminum frames.

Grader Shells

Grader Shells

We also carry grader shells, scalper reels, indent shells, and ball racks, along with a full supply of durable hand screens and sieves in a variety of materials and sizes. Specialty order hand screens are also available.

Hand Screens & Sieves

Hand Screens & Sieves

We begin by assessing your needs from technology to capacity, so we can accurately match you to the proper equipment for your grain cleaning operation. After we find the right machine for your farm or commercial operation, we work with you to determine the correct size and type of screen.

We hand screen grain samples for size and quality, so we can provide you with an accurate recommendation of screen sizes. Then we decide between wood or aluminum frames, wire meshes, or specialty orders, as well as any other accessories or add-ons.

All of our screens are manufactured in-house out of our Grain Systems shop in Saskatoon, Saskatchewan.

Experience

When it comes to our screen division, it is our people that really make the difference. From sales and operations to carpentry and welding, our team has long-term experience in the Grain Systems industry.

With over 20 years of experience with Flaman, Roy prides himself on getting the right equipment in front of his customers. Roy’s extensive grain cleaning knowledge and his passion for helping find solutions for his customers is the foundation of the Grain Systems team.

“My favourite part of working with this team is the people. We have a lot of fun here, too.”

Roy, Shop Manager & Grain Systems Analyst

Roy, Shop Manager & Grain Systems Analyst

With a smile, Mike keeps the sales and operations side organized and running smoothly in a busy atmosphere.

Mike, Grain Systems Sales

Mike, Grain Systems Sales

Our screen manufacturers are integral to the shop and the Grain Systems team. They are consistent, hard-working, and skilled woodworking and metal manufacturers. Gerwin has been with the company for over 12 years, and Wency has been part of the team for 10 years.

Wency, Screen Manufacturer

Both Gerwin and Wency are motivated by family and take great pride in their work. Their happy attitudes and humour make all the difference in making the workplace a positive environment.

Gerwin, Screen Manufacturer

From Start to Finish

At Flaman Grain Systems, we believe in supporting you from start to finish – from screen manufacturing and operations, right up to processing plants and turn-key grain system installations. This includes supplying, installing, and servicing various grain cleaners, bucket elevator systems, and other grain handling equipment.

copy.jpg)

With our unmatched inventory and long-term experience, Flaman is a great choice for your next custom screen project.

When you buy from us you are not just buying a product, you are gaining the ongoing support of a team with over 50 years of experience.

-----

If you have any questions about screen manufacturing, or any of our on-farm or commercial grain cleaners, grain dryers, or grain handling equipment, contact us or visit your nearest Flaman location.

Posted in Division News | Tagged with grain systems grain cleaning grain cleaners screen manufacturing perforated screens custom screens processing plants | More articles by Calla Simpson

From start to finish, the Flaman Grain Systems team is right beside you

Posted by Mitch Flaman Apr 07, 2021

At Flaman, we understand that investing in your farming operation and expanding your yard site is important for continued growth and efficiency. That’s why we believe in supporting you from start to finish.

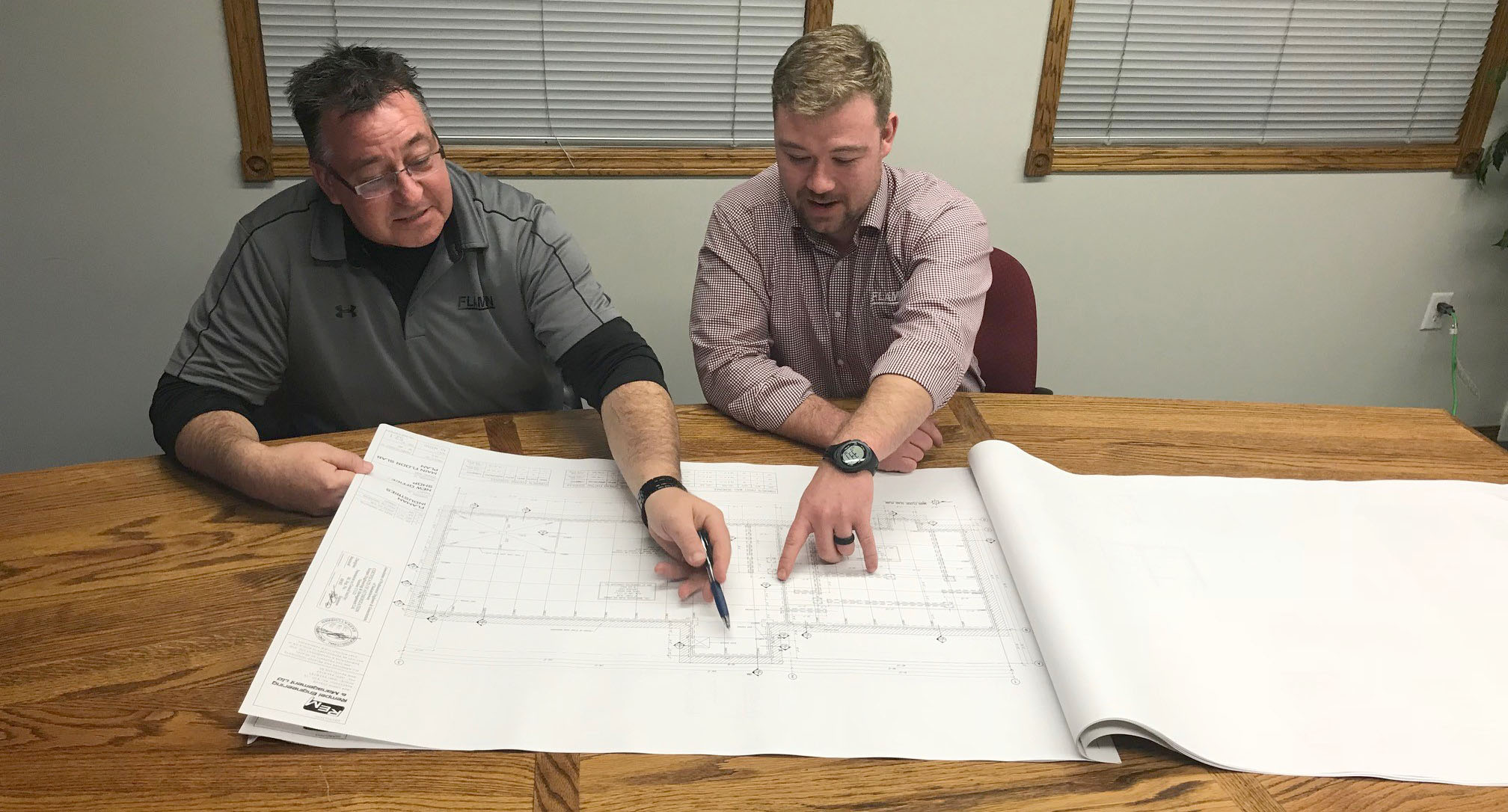

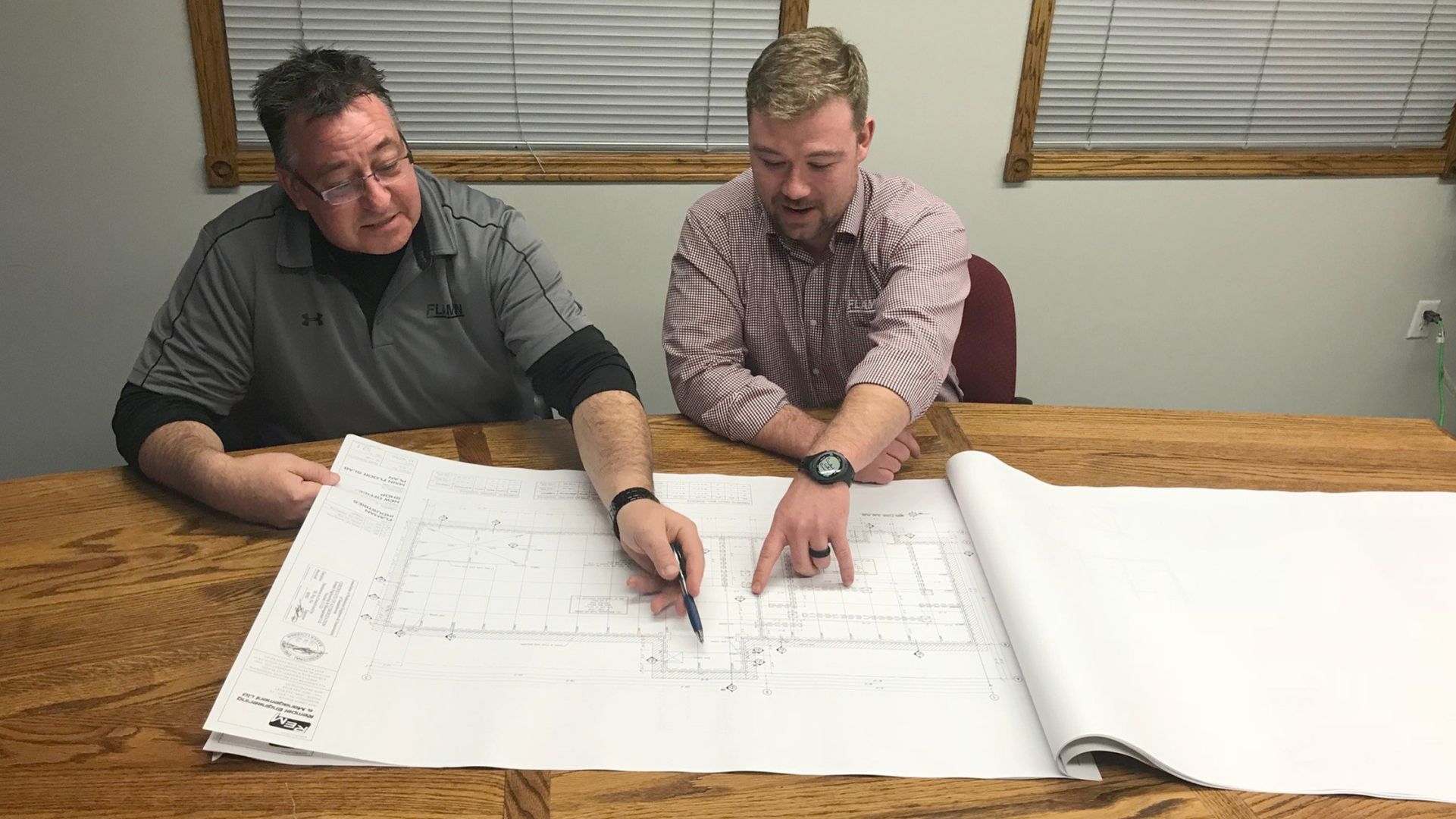

Customers share their experiences working with the Flaman team for their drying & handling setups (above)

Our Grain Systems team are experts in grain handling, grain drying, and grain cleaning. When you buy from us you are not just buying a product, you are gaining the ongoing support of a team with over 50 years of experience.

From Start to Finish

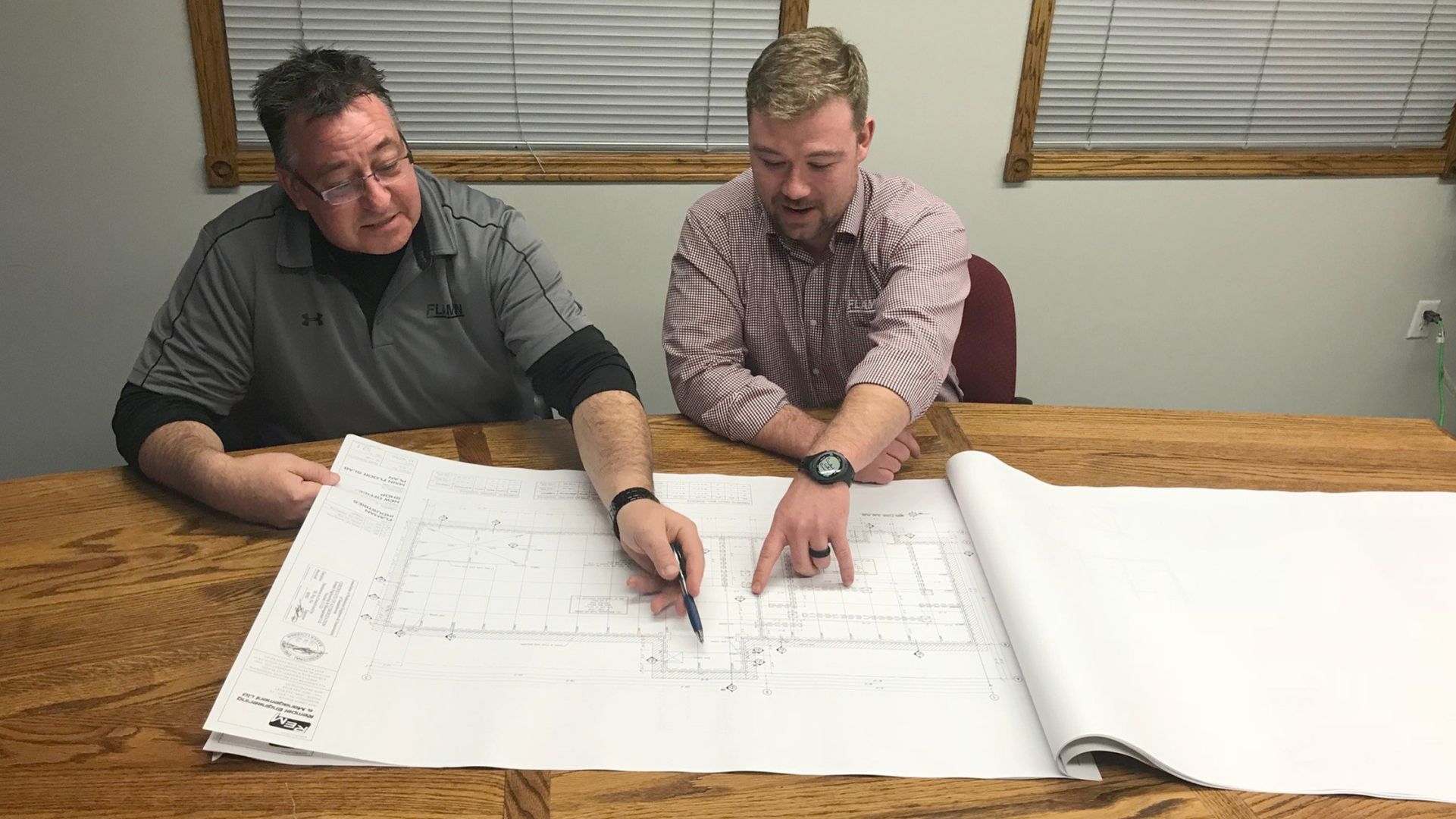

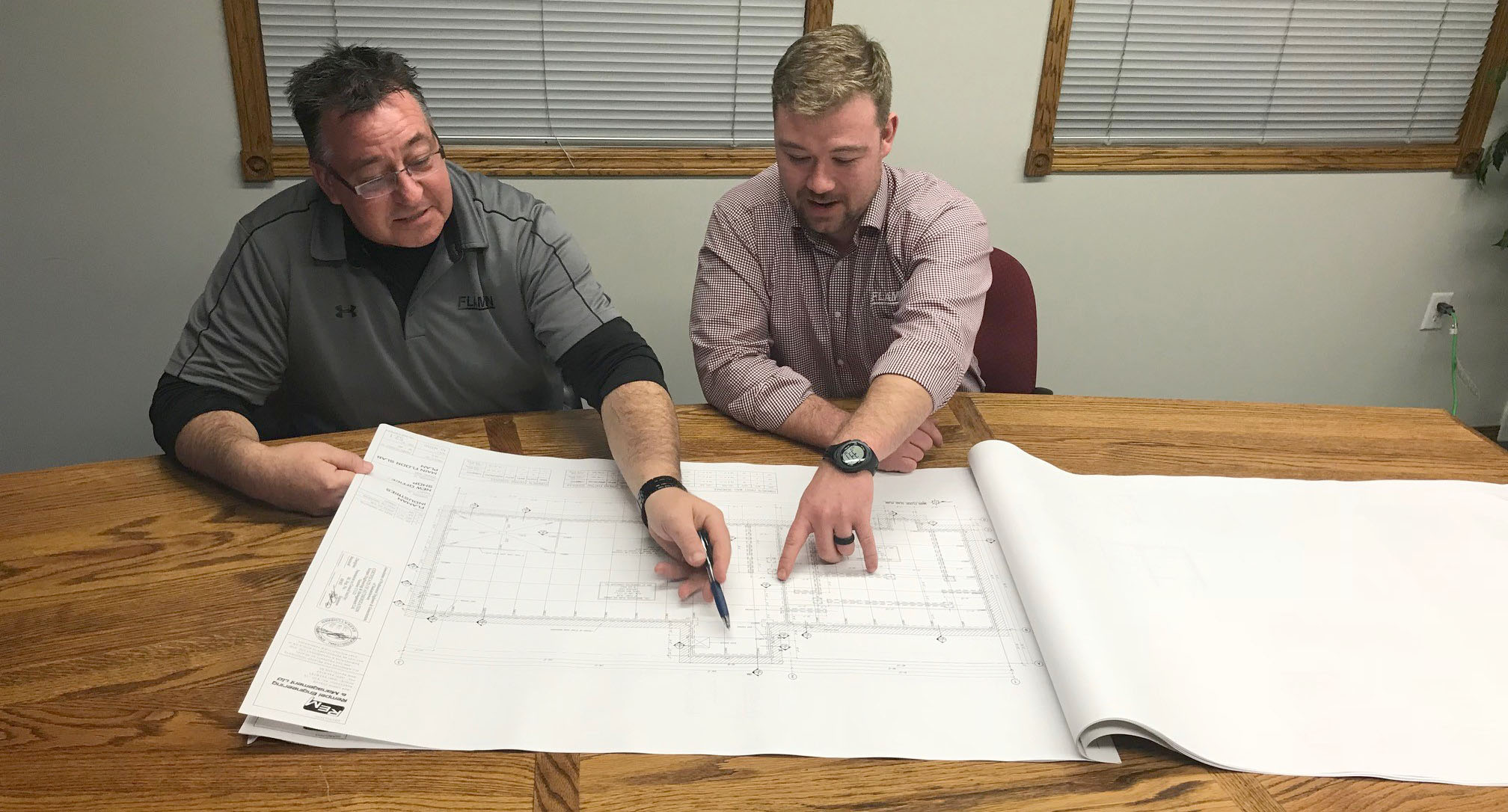

One of our industry experts will sit down with you to discuss and understand what your needs are for the coming year, as well as any future plans you may have. From there we will design a phased approach, with future expansion in mind.

We provide complete engineered drawings constructed in-house, with multiple alternatives to come up with a solution that works for your operation.

Once the equipment is decided on, we will continue to work with you through the site preparation and construction. Our job is not done until your equipment is handling grain the way you expect it to. And even then, we don’t consider our job to be done. Rather, we shift our focus to make sure you remain satisfied with the performance of your equipment.

That’s where our Service Team comes in. This dedicated team of certified technicians specializes in after sales support including warranty, pre-season and post-season maintenance, optimization, and commissioning of your machines to ensure your equipment is always running at peak performance.

Our Service Team Lead explains what you can expect from our team even after the sale (above)

We also offer access to a customer service hotline with live tech support after hours (in season only).

When you buy from us you are not just buying the equipment, you are buying the total solution. We have been here for over 60 years and we look forward to continuing to grow with you as your farming operation grows.

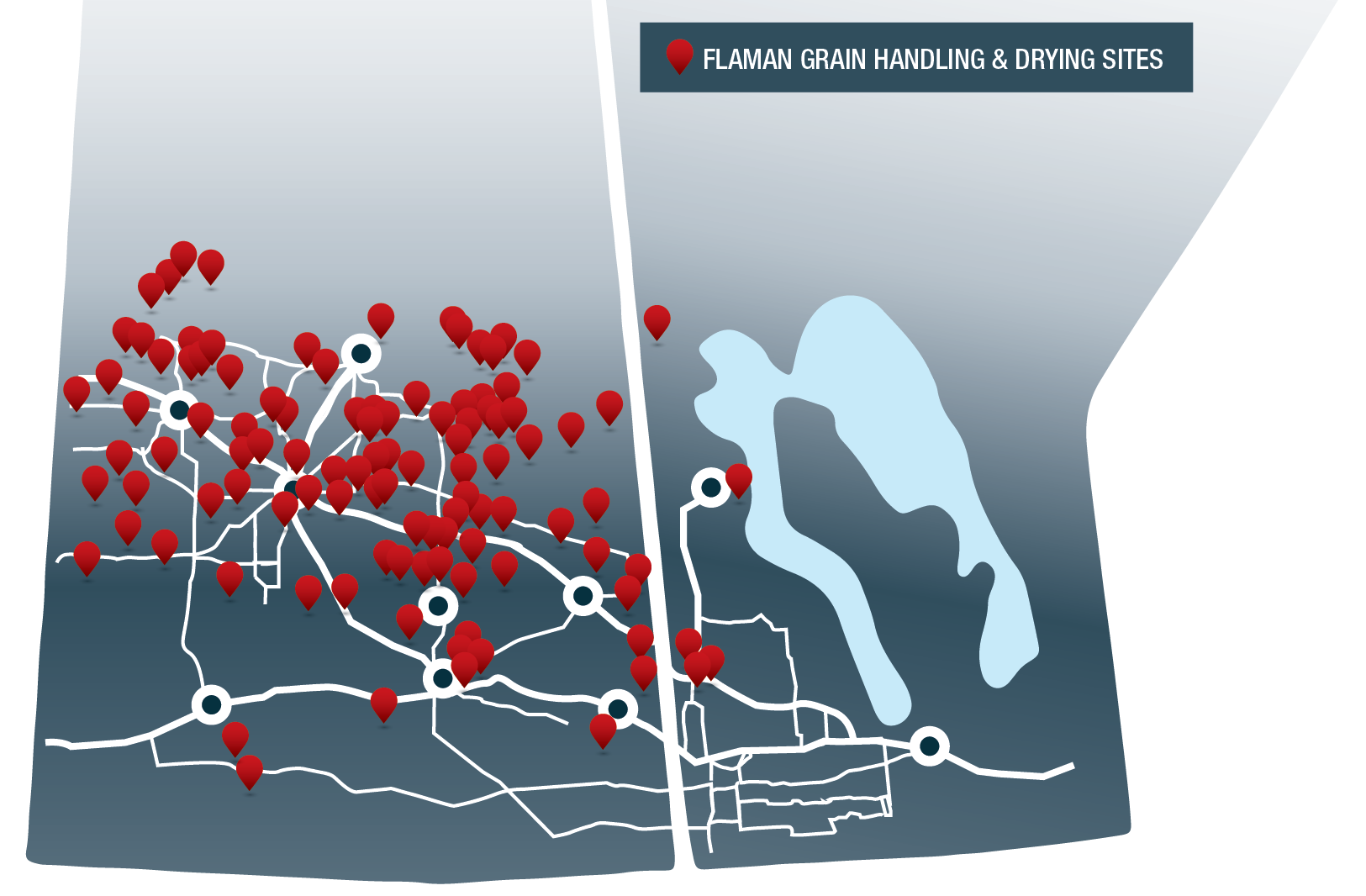

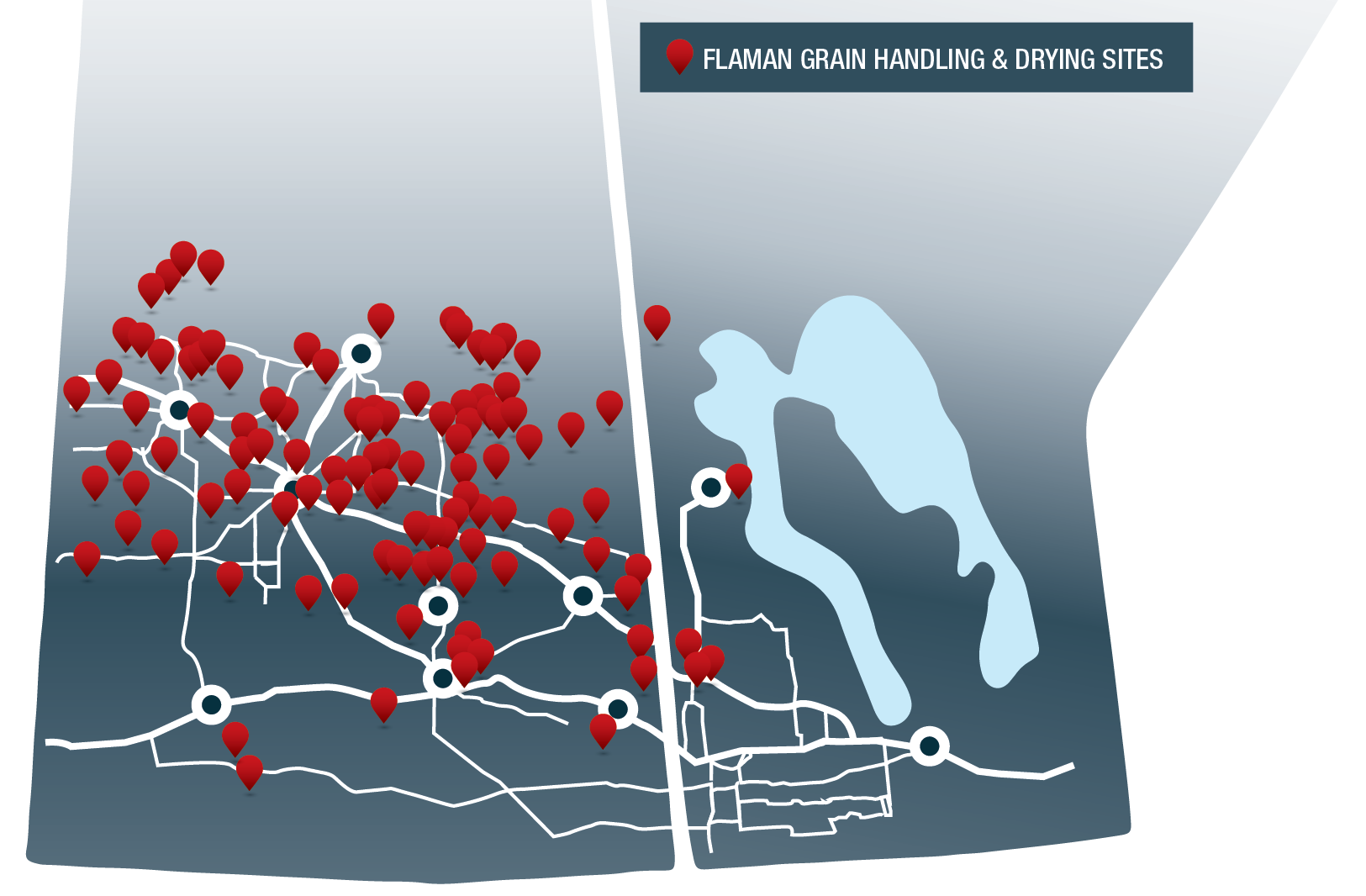

Map of Flaman Grain Handling and Drying sites throughout Saskatchewan & Manitoba (2021)

-----

If you are considering adding grain handling, drying, or cleaning equipment to your farm, give us a call or talk to one our Grain Systems specialists at your nearest Flaman location.

Posted in Division News | Tagged with grain systems grain handling grain drying grain cleaning optimization site drawings yard planning | More articles by Mitch Flaman

From start to finish, the Flaman Grain Systems team is right beside you

Posted by Mitch Flaman Apr 07, 2021

At Flaman, we understand that investing in your farming operation and expanding your yard site is important for continued growth and efficiency. That’s why we believe in supporting you from start to finish.

Customers share their experiences working with the Flaman team for their drying & handling setups

Our Grain Systems team are experts in grain handling, grain drying, and grain cleaning. When you buy from us you are not just buying a product, you are gaining the ongoing support of a team with over 50 years of experience.

From Start to Finish

One of our industry experts will sit down with you to discuss and understand what your needs are for the coming year, as well as any future plans you may have. From there we will design a phased approach, with future expansion in mind.

We provide complete engineered drawings constructed in-house, with multiple alternatives to come up with a solution that works for your operation.

Once the equipment is decided on, we will continue to work with you through the site preparation and construction. Our job is not done until your equipment is handling grain the way you expect it to. And even then, we don’t consider our job to be done. Rather, we shift our focus to make sure you remain satisfied with the performance of your equipment.

That’s where our Service Team comes in. This dedicated team of certified technicians specializes in after-sales support including warranty, pre-season and post-season maintenance, optimization, and commissioning of your machines to ensure your equipment is always running at peak performance.

Our Service Team Lead explains what you can expect from our team even after the sale

We also offer access to a customer service hotline with live tech support after hours (in season only).

When you buy from us you are not just buying the equipment, you are buying the total solution. We have been here for over 60 years and we look forward to continuing to grow with you as your farming operation grows.

Map of Flaman Grain Handling and Drying sites throughout Saskatchewan & Manitoba (2021)

-----

If you are considering adding grain handling, drying, or cleaning equipment to your farm, give us a call or talk to one our Grain Systems specialists at your nearest Flaman location.

Posted in Division News | Tagged with grain systems grain handling grain drying grain cleaning optimization site drawings yard planning | More articles by Mitch Flaman

Move your grain with the all-new AGI Hutchinson Double Run Chain Conveyor

Posted by Paul Boechler Sep 14, 2020

The AGI Hutchinson Double Run Chain Conveyor is a brand new product to the Flaman lineup. It is built in Western Canada with the prairie farmer in mind. Manufactured at AGI’s plant in Swift Current, SK, it is designed to handle delicate crops grown on the prairies, like pulses, far more gently than an auger would.

The UHMW plastic paddles gently convey grain

Maneuverable in Tight Spaces:

Modeled after the clean grain elevator on your combine, its UHMW plastic paddles convey crops to your bin in a gentle manner. A huge benefit of this is the ability to operate at full capacity from nearly any angle, fitting into tighter spaces.

Another feature of the Double Run is the easy to use swivel arc kit, which makes the unit highly portable around the yard. You can move it from bin to bin or dryer, by simply swapping a few pins.

The swivel arc kit allows for easy maneuverability

Low Power Requirements:

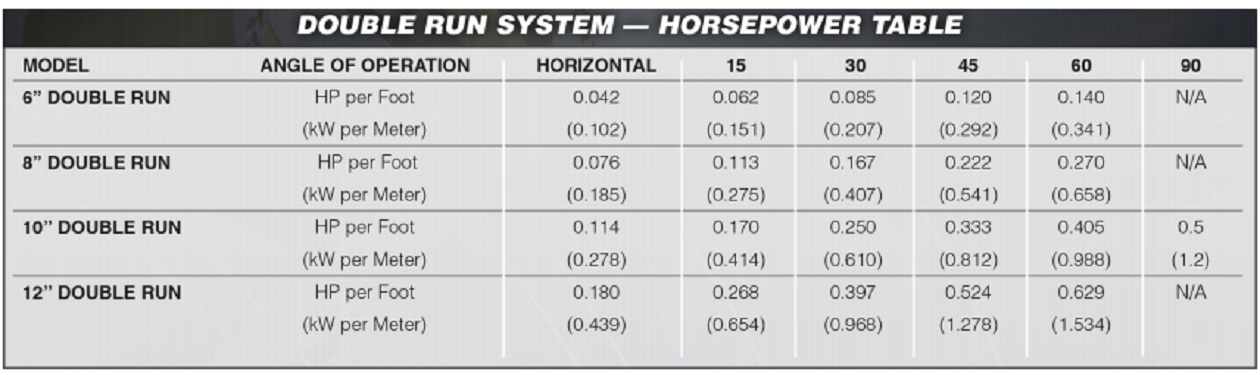

While the Double Run is powerful in getting your grain into the bin, it has a low horsepower requirement compared to alternative grain handling equipment. As an example, 8” model with a length of 82’ requires just 18 HP at a 45° angle (see chart below). These units are available with an electric motor or PTO drive, giving you plenty of power options.

Proven Reliability & Longevity:

We all know an unreliable auger can be a huge problem for your operation at harvest time. The Double Run was designed as a solution to this problem. The chain conveyor requires less maintenance and has more longevity than your typical auger. Keep the chain running straight and tensioned properly, and these units will just run. And run. And run.

Travis Frey of AGI walks us through exactly what makes this unit different:

The Double run comes in lengths of up to 82’ on the 8” and 10” models, with up to 4,000 BPH capacity on the 8” and 6,000 BPH on the 10”. It is also available in a 12” model, which has a 10,000 BPH capacity and lengths up to 130’.

Stop by your local Flaman Ag store or give us a call for more information on this unit.

Posted in New Products | Tagged with AGI Hutchinson Double Run chain conveyor grain handling grain systems Flaman | More articles by Paul Boechler

Reduce labour when filling bins: Automate your grain handling site with a Walinga Blower System

Posted by Calla Simpson Aug 31, 2020

A Walinga Pneumatic Blower System may be one of the most versatile pieces of equipment you can add to your Grain Handling lineup. The Ultra-Veyor is designed to fill bins of various heights and distances from the ground up, allowing you to easily add the system to any pre-existing site.

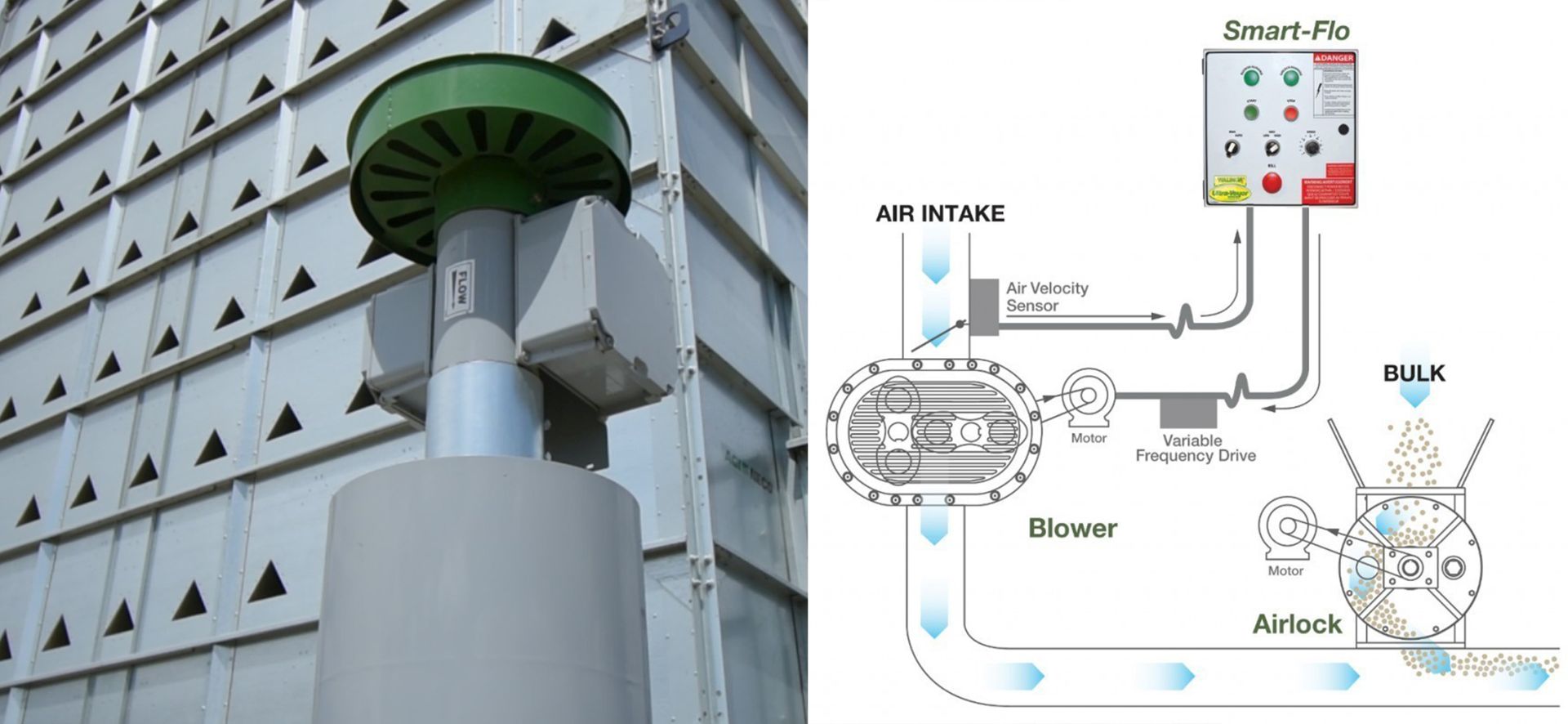

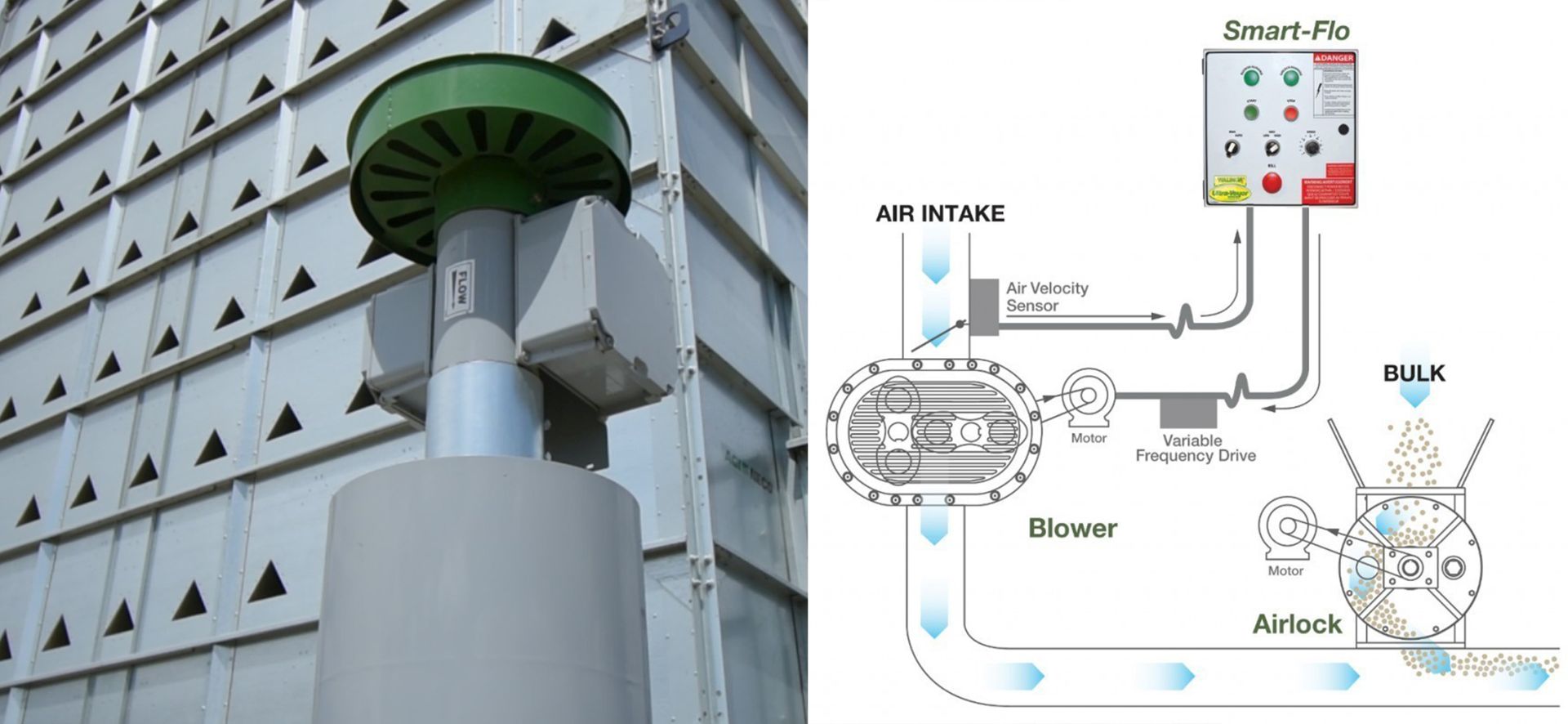

Walinga Sales Rep Doug Termeer explains how a blower system works

Many yard sites weren’t originally designed with the thought of adding a grain handling system or grain dryer down the line. As farms continue to grow, larger bins are being installed and grain storage is being built further and further away. The only way to hit all these bins of different sizes and distances economically is with a blower system. By allowing you to keep the current bins and other infrastructure you have already invested in, a Walinga Ultra-Veyor prevents you from having to redesign your entire yard site – saving you a lot of money in the long run.

A grain handling setup in Saskatchewan utilizing a Walinga blower system to reach bins of various heights

A grain handling setup in Saskatchewan utilizing a Walinga blower system to reach bins of various heights

Walinga blower systems are also very flexible and expandable, so you don’t need to have your whole yard designed and planned out ahead of time. You can easily expand down the road as your business grows and you start to add more acres or dry more grain. These systems can be installed under driveways to reduce the risk of damaging any pipes as you load/unload trucks in your yard.

The Walinga Ultra-Veyor is also a great add-on to any grain dryer, especially continuous flow dryers like NECO. Automating your grain dryer and grain handling reduces the number of augers, legs, and additional trucking necessary to move grain around your yard. This maximizes accessibility to any drying or storage facility. Your grain can go straight from the dryer into the final storage bin, so you don’t have to move it around multiple times before you get it where you want it in the end. It’s faster, more efficient, and most importantly, safer.

A NECO Grain Dryer unloading into a Walinga system

With the Smart-Flo feature on your Walinga blower, you have the ability to control the airspeed which reduces unnecessary damage to product and piping. This Variable Frequency Drive (VFD) system monitors and adjusts motor speeds depending on crop type, volume of product, and distance – optimizing performance and reducing energy costs. The Smart-Flo system can also be wired into your continuous flow grain dryer to speed up and slow down as necessary.

A blower system is not only an economic and affordable solution for long-distance conveying, it is also simple to install and is gentle on product – moving grain virtually dust and damage-free. Walinga Ultra-Veyors can move anywhere from 400 bushels/hour to 2,100 bushels/ hour, depending on the size of your operation.

Hear first-hand how a Walinga Ultra-Veyor made a positive impact on this customer's operation

Want to invest in a Walinga Pneumatic Blower system and automate your grain handling site this year? Contact us to schedule a free, no-commitment site assessment today.

-----

For more information on our grain handling and grain drying solutions, talk to one of our agriculture specialists at your nearest Flaman location.

Posted in Product Information | Tagged with grain systems grain handling Walinga Ultra-Veyor blower system NECO grain dryer | More articles by Calla Simpson

Reduce labour when filling bins: Automate your grain handling site with a Walinga Blower System

Posted by Calla Simpson Aug 31, 2020

A Walinga Pneumatic Blower System may be one of the most versatile pieces of equipment you can add to your Grain Handling lineup. The Ultra-Veyor is designed to fill bins of various heights and distances from the ground up, allowing you to easily add the system to any pre-existing site.

Walinga Sales Rep Doug Termeer explains how a blower system works

Many yard sites weren’t originally designed with the thought of adding a grain handling system or grain dryer down the line. As farms continue to grow, larger bins are being installed and grain storage is being built further and further away. The only way to hit all these bins of different sizes and distances economically is with a blower system. By allowing you to keep the current bins and other infrastructure you have already invested in, a Walinga Ultra-Veyor prevents you from having to redesign your entire yard site – saving you a lot of money in the long run.

A grain handling setup in Saskatchewan utilizing a Walinga blower system to reach bins of various heights

A grain handling setup in Saskatchewan utilizing a Walinga blower system to reach bins of various heights

Walinga blower systems are also very flexible and expandable, so you don’t need to have your whole yard designed and planned out ahead of time. You can easily expand down the road as your business grows and you start to add more acres or dry more grain. These systems can be installed under driveways to reduce the risk of damaging any pipes as you load/unload trucks in your yard.

The Walinga Ultra-Veyor is also a great add-on to any grain dryer, especially continuous flow dryers like NECO. Automating your grain dryer and grain handling reduces the number of augers, legs, and additional trucking necessary to move grain around your yard. This maximizes accessibility to any drying or storage facility. Your grain can go straight from the dryer into the final storage bin, so you don’t have to move it around multiple times before you get it where you want it in the end. It’s faster, more efficient, and most importantly, safer.

A NECO Grain Dryer unloading into a Walinga system

With the Smart-Flo feature on your Walinga blower, you have the ability to control the airspeed which reduces unnecessary damage to product and piping. This Variable Frequency Drive (VFD) system monitors and adjusts motor speeds depending on crop type, volume of product, and distance – optimizing performance and reducing energy costs. The Smart-Flo system can also be wired into your continuous flow grain dryer to speed up and slow down as necessary.

A blower system is not only an economic and affordable solution for long-distance conveying, it is also simple to install and is gentle on product – moving grain virtually dust and damage-free. Walinga Ultra-Veyors can move anywhere from 400 bushels/hour to 2,100 bushels/ hour, depending on the size of your operation.

Hear first-hand how a Walinga Ultra-Veyor made a positive impact on this customer's operation

Want to invest in a Walinga Pneumatic Blower system and automate your grain handling site this year? Contact us to schedule a free, no-commitment site assessment today.

-----

For more information on our grain handling and grain drying solutions, talk to one of our agriculture specialists at your nearest Flaman location.

Posted in Product Information | Tagged with grain systems grain handling Walinga Ultra-Veyor blower system NECO grain dryer | More articles by Calla Simpson

Early season utilization: Increase the grade of your grain with a NECO Grain Dryer

Posted by Calla Simpson Aug 26, 2020

As harvest is well underway in most areas of the province, many producers are utilizing their grain dryers early on this season and increasing the available window to combine. Some farmers have even noticed increases in their durum quality as their grade improves after drying.

20% moisture durum before going into the NECO grain dryer (left) and 14.5% moisture durum after being dried (right)

20% moisture durum before going into the NECO grain dryer (left) and 14.5% moisture durum after being dried (right)

Nolan Gettis, a farmer in central Saskatchewan, discusses how his NECO Grain Dryer has improved his operation:

“Two years ago, I would have been waiting to combine saying, ‘It’s getting close’. Right now, I’m full on harvesting because I have this dryer as a tool. I’m not waiting to use it. I’m literally taking off 20% durum and it’s coming out dry and just shining. It’s amazing how much better this durum looks once it comes out of that dryer. When you have a crop of unicorn #1 amber durum, you’ve gotta go get it.

I’d have to say the biggest benefit of this NECO dryer is that we’ve taken on more acres this year and I’ve already conquered that land without buying another combine. I have three bins on the go; a dry bin, an aeration bin, and the dryer. It’s a total harvest management tool.”

Nolan's grain drying setup in Semans, SK

Mixed flow dryers reduce the risk of crop damage, resulting in higher test weights. This drying process helps mature the kernels and brings out the rich colour evenly, producing higher quality grain with more consistent results. This dramatic difference in quality increases profitability and improves yield.

It's not too late – contact us to book your dryer install with Flaman today.

-----

For more information on our grain handling and grain drying solutions, talk to one of our agriculture specialists at your nearest Flaman location.

Posted in Product Information | Tagged with grain systems grain handling grain drying NECO grain dryer mixed flow continuous flow | More articles by Calla Simpson

Early season utilization: Increase the grade of your grain with a NECO Grain Dryer

Posted by Calla Simpson Aug 26, 2020

As harvest is well underway in most areas of the province, many producers are utilizing their grain dryers early on this season and increasing the available window to combine. Some farmers have even noticed increases in their durum quality as their grade improves after drying.

20% moisture durum before going into the NECO grain dryer (left) and 14.5% moisture durum after being dried (right)

20% moisture durum before going into the NECO grain dryer (left) and 14.5% moisture durum after being dried (right)

Nolan Gettis, a farmer in central Saskatchewan, discusses how his NECO Grain Dryer has improved his operation:

“Two years ago, I would have been waiting to combine saying, ‘It’s getting close’. Right now, I’m full on harvesting because I have this dryer as a tool. I’m not waiting to use it. I’m literally taking off 20% durum and it’s coming out dry and just shining. It’s amazing how much better this durum looks once it comes out of that dryer. When you have a crop of unicorn #1 amber durum, you’ve gotta go get it.

I’d have to say the biggest benefit of this NECO dryer is that we’ve taken on more acres this year and I’ve already conquered that land without buying another combine. I have three bins on the go; a dry bin, an aeration bin, and the dryer. It’s a total harvest management tool.”

Nolan's grain drying setup in Semans, SK

Mixed flow dryers reduce the risk of crop damage, resulting in higher test weights. This drying process helps mature the kernels and brings out the rich colour evenly, producing higher quality grain with more consistent results. This dramatic difference in quality increases profitability and improves yield.

It's not too late – contact us to book your dryer install with Flaman today.

-----

For more information on our grain handling and grain drying solutions, talk to one of our agriculture specialists at your nearest Flaman location.

Posted in Product Information | Tagged with grain systems grain handling grain drying NECO grain dryer mixed flow continuous flow | More articles by Calla Simpson

Dry your grain with ease: Get ahead of harvest this year and book your NECO dryer install with Flaman today

Posted by Calla Simpson Jun 26, 2020

There are many advantages to owning a grain dryer. As we learned last year in Western Canada, harvest 2019 had its challenges; most of which showed up when the crop needed to come off the field. Being able to dry your grain allows you to better manage your timeline and start combining as soon as it’s time to go! The earlier you can get started, the less likely you are to get caught with crop out in the field over winter.

NECO Mixed Flow Grain Dryers are designed to easily and efficiently condition all types of grain for storage. With no screens to clean or unplug, this industry-leading grain dryer is designed not only for its performance, but also its versatility.

The flexible, modular design of these grain dryers make for easy installation and can be customized and expanded to suit any farming operation.

A time lapse of a NECO Grain Dryer installation near Saskatoon

The NECO Grain Dryer’s mixed flow operation ensures even heating and cooling to provide consistent, high-quality grain. The improved air flow, quieter fans, and unequalled fuel efficiency make this dryer a valuable addition to any farming operation.

NECO dryers use Commander Control with a Dryer Master moisture control system to protect the quality of your grain and prevent over- or under-drying. The COMMANDnet system allows remote access to your NECO Grain Dryer to monitor its performance from your smartphone or computer – providing you with total control over your dryer wherever you may be.

It is never too early to start planning for harvest, as we never know what mother nature has in store for us. Bookings are filling up fast, but there are still a few spots left to get your name on a dryer for fall. Our Grain Systems team can customize a complete grain drying system to suit your needs, guiding the setup and installation, and providing service and maintenance along the way.

Hear first-hand from Flaman customers what a NECO dryer can do for your operation

Be ready to get ahead of harvest this year – contact us to book your dryer install with Flaman today.

-----

For more information on our grain handling and grain drying solutions, talk to one of our agriculture specialists at your nearest Flaman location.

Posted in Product Information | Tagged with grain systems grain handling grain drying NECO grain dryer | More articles by Calla Simpson

Dry your grain with ease: Get ahead of harvest this year and book your NECO dryer install with Flaman today

Posted by Calla Simpson Jun 26, 2020

There are many advantages to owning a grain dryer. Being able to dry your grain allows you to better manage your timeline and start combining as soon as it’s time to go! The earlier you can get started, the less likely you are to get caught with crop out in the field over winter.

NECO Mixed Flow Grain Dryers are designed to easily and efficiently condition all types of grain for storage. With no screens to clean or unplug, this industry-leading grain dryer is designed not only for its performance, but also its versatility.

The flexible, modular design of these grain dryers make for easy installation and can be customized and expanded to suit any farming operation.

A time lapse of a NECO Grain Dryer installation near Saskatoon

The NECO Grain Dryer’s mixed flow operation ensures even heating and cooling to provide consistent, high-quality grain. The improved air flow, quieter fans, and unequalled fuel efficiency make this dryer a valuable addition to any farming operation.

NECO dryers use Commander Control with a Dryer Master moisture control system to protect the quality of your grain and prevent over- or under-drying. The COMMANDnet system allows remote access to your NECO Grain Dryer to monitor its performance from your smartphone or computer – providing you with total control over your dryer wherever you may be.

It is never too early to start planning for harvest, as we never know what mother nature has in store for us. Bookings are filling up fast, but there are still a few spots left to get your name on a dryer for fall. Our Grain Systems team can customize a complete grain drying system to suit your needs, guiding the setup and installation, and providing service and maintenance along the way.

Hear first-hand from Flaman customers what a NECO dryer can do for your operation

Be ready to get ahead of harvest this year – contact us to book your dryer install with Flaman today.

-----

For more information on our grain handling and grain drying solutions, talk to one of our agriculture specialists at your nearest Flaman location.

Posted in Product Information | Tagged with grain systems grain handling grain drying NECO grain dryer | More articles by Calla Simpson

Be ready for harvest 2020: Summer is the time to build your bins & install your grain handling equipment

Posted by Calla Simpson May 29, 2020

As seeding is coming to a close throughout the province, you may be starting to think about the next steps in your farming operation for 2020. This likely includes thoughts of additional Grain Storage, Grain Handling, and even Grain Drying equipment.

It may seem early to plan for harvest, but summer is a great time to build your bins and install your grain handling equipment to move the crop come harvest time. Buying now will ensure your equipment is installed and ready to go in the fall – so you can have peace of mind all season long.

Lean on the Pros

At Flaman, our Grain Systems team is equipped to work with you on developing your yard for the future. Let one of our industry experts come to your yard to measure, draw, and discuss your needs for the coming year. Our tactical approach provides you with various drawings and site layouts that can utilize your existing equipment, and plan for future expansion in a multi-phased strategy.

Our Specialists can create a yard design based on your operational needs and the desired function of your site.

Our Specialists can create a yard design based on your operational needs and the desired function of your site.

We specialize in full grain handling setups, including a wide range of bucket elevators and pneumatic conveyors – such as the Walinga Ultra-Veyor. Our turn-key offering also includes grain dryer systems, like the NECO Mixed Flow Dryer, as well as grain cleaning and processing facilities, automated bin sites, and producer loading sites. Our team is here to guide the entire setup and installation process of your grain handling system and provide maintenance and service for every item that goes in and out of our doors.

Schedule your appointment today for a free, no commitment site assessment.

-----

For more information on our grain handling and grain drying solutions, talk to one of our agriculture specialists at your nearest Flaman location.

Posted in Ag news | Tagged with grain systems grain handling grain drying grain cleaning turnkey bin site NECO Walinga | More articles by Calla Simpson

Locations

Locations

.JPG)