Flaman Rentals Blog

RSS feed

Categories

Recent activity

- What's it like being a Flaman Rental Dealer?

- A Brief History of the Newest Flaman Store in Swift Current

- Disney's NEW Leadership Excellence Training Course

- Disney's Approach To Quality Service

- Disney's Approach To Quality Service

- Trailering 'Rules of the Road' Updated

- 10th Annual Frank J. Flaman Foundation Gala 2016

- Why Frank Cares

Authors

Archive

Choosing The Right Pressure Washer for Your Job

Posted by Jeff Brown Nov 19, 2025

Different Needs. Different pressure washers.

There are many units to choose from - gas or electric, cold water, with a range of flow rates, PSI ratings, sizes and features. Finding the best one for you comes down to what kind of cleaning you will need to do.

Start with the basics.

- "First do no harm" applies here as it does in medicine. Too much pressure, measured in pounds per square inch (PSI) and volume, AKA flow rate or GPM (gallons per minute), can tear through dirt, paint, or stain, then do the same to the fragile wood, plastic, or light metal surface you want to protect.

- Too little pressure can make removing serious grime from heavy equipment or concrete floors and walls impossible. Attempting heavy-duty cleaning jobs takes time that busy contractors and farmers can't afford.

The PSI rating alone can give you a good idea of what kind of washer you're looking for:

- Residential Light - Duty (Electric) 300- 1999 PSI

- Residential Medium - Duty (Electric) 2000- 3299 PSI

- Industrial Heavy-Duty Cleaning (Gas) 3300 - 4600+ PSI

Where will you be using your pressure washer?

- Will you be close to the house with access to power and water, or will you be out in the middle of nowhere with neither?

- Most electric-motor models can't range farther than the reach of their hose or power cord.

- Heavier gas-powered pressure washers have large built-in water and fuel capacities, allowing them to work in fields or on other remote job sites.

Other Advantages of Electric and Gas Washers

- Ease of use: Electric motors have the advantage of easier startup and a lightweight, compact build that makes them easier to move around and store. With no emissions and quieter operation, they reduce health risks and help you keep the peace with your neighbors.

- Toughness: In addition to durability and longevity, gas models' heavier construction, including solid steel cages, protects their components from damage. Features like flat-free tires make them easier to handle on uneven terrain.

Hot Water Pressure Washers vs. Cold Water Pressure Washers

- Hot water breaks down or "melts" grease, grime and other chemicals that cold water struggles to budge. It's generally considered the solution for tough cleaning jobs.

- Cold water removes dirt from more sensitive surfaces that hot water can damage. It also eliminates steam, which can obstruct your view of your work.

Call or visit your nearest Flaman location, and we'll help you zero in on the ideal unit for your home, farm, or business.

Posted in Product Information | More articles by Jeff Brown

An Unconventional Way to Dry Grain in A Wet Harvest Year

Posted by Jeff Brown Nov 05, 2025

When farmers are in a race to get remaining crops off the field, their go-to solution is grain drying. We offer the highly efficient AGI NECO Grain Dryer, which can be scaled to the size of your operation, Its innovative mixed-flow system sets the pace for quick drying, helping you minimize spoilage and maintain the grade of your grain. However, dryer installs rely on many environmental and logistical factors. These limit the likelihood of having a dryer up and running before the end of a harvest, particularly in a wet year.But farmers are nothing if not resourceful in the face of hardship, and they’ve shared some unconventional “in a pinch” grain drying methods online. Be advised that risks naturally apply when employing improvised ideas, so you’ll need to take some safety precautions if you try them.

One unconventional online farm solution inspired the idea of using the Frost Fighter Portable Heater (available only at our Saskatchewan locations) for a new and helpful use. This diesel-powered 350,000 BTU industrial heater is designed to heat remote construction sites and shops. They can be adapted to a bin aeration system and pump heat into two bins simultaneously. Again, this isn’t a perfect solution, nor is it manufacturer-recommended, but for some it has been an effective outside-the-box solution in desperate times.

If you find yourself in a wet harvest season and unable to use a grain dryer, this makeshift option could help you salvage a tough harvest.

Interested in learning more about grain drying? Speak with one of our agricultural specialists at your nearest Flaman location.

Posted in Product Information | More articles by Jeff Brown

Order Your Grain Cart Parts Early - Performance Checklist

Posted by Jeff Brown Jul 08, 2025

Combine inspections are important before harvest, but don’t forget about inspecting and test running your grain cart, as well. It could save you an emergency trip to purchase parts – especially in-demand items like PTO shafts, flighting, gearboxes, bearings, bushings.

Don’t forget the reason they’re in demand is because a lot of farmers will need them, so they might be out of stock by the time you get to your parts supplier.

So, it’s best to be proactive and make sure your grain cart is properly maintained, and you’ve identified the parts you might need to replace before the repair rush begins. Ordering them in advance of the busy harvest season can potentially save you time, money, and frustration.

.jpg)

Performance Inspection Checklist

Checking and testing your equipment during the summer can prevent issues in the field in October. Use this checklist to figure out which grain cart parts to replace or keep on hand before harvesting starts.

Pre-Startup Inspection:

Grease all grease points and visually inspect while greasing. Look for:

- Bearing wobble

- Missing Linkage

- Unaligned rollers

Check your auger tube

- With the auger folded up in the storage position, check the bottom flighting to make sure it's not too worn out or bent

- Check for possible leak spots in your tube. Bushels of grain can be lost through holes worn by the auger.

Check PTO

- If you have a new tractor, make sure it still fits. If you’ve upgraded, last year’s 540 RPM shaft could be a small 1000 now.

Check Gearbox

- Make sure there’s oil in it and it’s turning properly

Startup

Not everyone is able to do this, but if you can see what needs replacing in the yard, you won’t have to find out what needs replacing in the field.

Fire up your grain cart. Do a thorough walk-around and listen carefully for bearings making odd sounds.

Tow it around the yard to make sure:

- Its tracks are turning

- Nothing's seized

- Your gearbox isn’t piled up

Check your flighting. Make sure it’s spinning properly, and all the linkage is well-attached and free of damage or wear.

You can even check performance under load.

- Move a little bit of product through, whether you just rotate some grain out of a bin into the same bin or into another bin.

When should you inspect?

Between seeding and in-crop? Between in-crop and harvest? The best answer is the sooner the better – especially if you want to get ahead of parts demand and get in on shipping without freight charges.

Call or visit your nearest Flaman location to learn more about ensuring you’ll have the right harvest parts when you need them.

Posted in Product Information | More articles by Jeff Brown

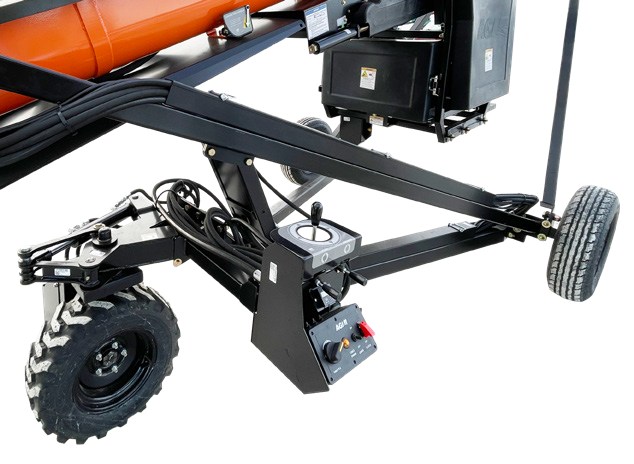

Is the J&M Inline Tandem Axle Grain Cart Right for You?

Posted by Jeff Brown Jun 30, 2025

J&M's inline tandem dual-axle grain cart demonstrates how tires can work on larger grain carts that usually run on tracks.

If you’re dealing with wet field conditions or have serious compaction issues, tracks are the answer. However, not every farm needs to go to the extra expense. That’s why J&M designed a model that offers the mobility and maneuverability of tires plus better floatation than single-wheel carts can deliver – at a lower price tag than you’d pay for tracks. But that’s not all.

.jpg) Steer in Reverse

Steer in Reverse

Unique Tandem Dual-Axle Benefits

Steer in Reverse! The tandem in-line design includes one steering axle. This in-line dual gives the grain cart much greater maneuverability, including the ability to steer while backing up. That’s a big help in fields shaped by surrounding brush and trees or in tight spots around the bin yard. It also helps you make sharper turns and eliminates tire drag when you do – increasing the lifespan of your tires and hubs.

Safe Road Travel. The above benefit also makes the tandem-axle cart even quicker and easier to control on roads between your fields – an advantage that grain carts with tires already held over track models.

“Last year, J&M brought us a prototype to test,” says Darrell Knash of Flaman Ag Sales. “I took it out to one of my customers so he could try it out. He really liked the turning axle because it made it easier to get around in the field.”

.jpg) Wider tires on a tandem axle also improve floatation and comfort.

Wider tires on a tandem axle also improve floatation and comfort.

Working Benefits

Increased Stability. The wide wheelbase provides greater stability on uneven or rough terrain, reducing the risk of rollovers. That’s whether it’s empty or completely full, so farmers can have more confidence hauling maximum loads.

Hydraulic Suspension. The J&M tandem travels smoothly over changing ground contours thanks to 16” of consistent vertical movement. This system automatically adjusts to compensate for gradual hydraulic oil leakage, so you won’t need to constantly check fluids or measure cylinder movement with a measuring tape.

Wider tires on a tandem axle also improve floatation and comfort. Two tires instead of one gives the cart a wider footprint and a nicer ride across the field.

Lower Price. More Mobility. Less Maintenance.

Interested in an economical alternative to tracks? Call or visit your nearest Flaman location to learn more about J&M’s Tandem axle features, available on 1732, 2032, and 2332 models. Our knowledgeable staff can help you find the right model for your farming operation.

Posted in Product Information | More articles by Jeff Brown

What You Need to Build Your Own Basic Fire Suppression Kit

Posted by Jeff Brown Jun 19, 2025

If your property is in a potential wildfire path, we can help you create a firefighting suppression system with these five essential items.

Tanks

It’s helpful to have a nearby body of water to draw from, but if you don’t, we have storage tanks in several styles and sizes.

- Turtle Tanks, Low-Profile Tanks, 1250-gallon tanks. Mounted on your truck or trailer, they offer the benefit of mobility. Just check your payload capacity to make sure whatever you mount it on can handle the weight of the water you carry.

- Stationary Tanks. If you’re drawing water from a lake, dugout, or other body of water, the closer, the better. A pump’s lift (water pressure) weakens after travelling a limited number of feet.

Mitch profiles turtle, low-profile, and 1250-gallon tanks.

Hoses

A Suction Hose draws water from one of the sources described above. It attaches to the inlet on the side of the pump.

An Outlet Hose attaches to the outlet on top of the pump and expels water, either as a spray hose for dousing flames or a transfer hose for moving water. Lay-flat hoses are always outlet hoses.

High-volume suction hoses and powerful pumps

Filter Floats

These are used when you’re drawing water from a body of water, as opposed to a clean water tank. Filtering prevents rocks, mud, sand, weeds, and other obstructions from being drawn into your line and plugging or damaging your pump.

- The filter screens out everything but water.

- The float keeps the filters from sinking into the mud.

- The backcheck valve allows outward flow while preventing water from coming back in. It also keeps your hose full of water so your pump stays primed.

Mitch discusses filter functions and features for water pumps.

Pumps

We offer two types of pumps, both of which are essential to firefighting.

- High-pressure pumps are used for firefighting, having two advantages that enable them to spray further and allow you to fight flames from a safe distance:

- They're more effective than low-pressure pumps using the same-size hoses and outlets.

- They yield higher PSI at lower flow rates (like 126 GPM), thanks to 197’ of total lift.

- Low-pressure pumps, also known as water transfer pumps, are designed to move larger volumes of water at higher flow rates, like 260 GPM. However, with a lower total lift, like 185’, they're more suited to running sprinklers than spraying flames. They are also significantly less expensive.

Firefighting pumps available from Flaman

Fittings and Valves

Fittings and Valves give you control over your chosen firefighting technique, whether you’re using a spray hose or sprinklers.

- Valves attach to your pump or tank bulkhead, provided they match your diameter. They open, shut off, or regulate water flow.

- Fittings can be used to neck down output diameters and use narrower hoses (even your garden hose). This also increases your pressure PSI, which can enable you to spray water from a low-pressure pump.

Mitch talks fittings, cam locks, inlets, and outlets.

Learn More About Creating your Own Fire Suppression Kit

Call or stop by your nearest Flaman location. Our friendly staff will be happy to talk with you about your requirements and help you find your best fire suppression solution. Looking for an all-in-one solution?

Ask about our Fire Suppression Skids – easily mounted on a truck or trailer for quick response in remote communities or on farms.

Posted in Product Information | More articles by Jeff Brown

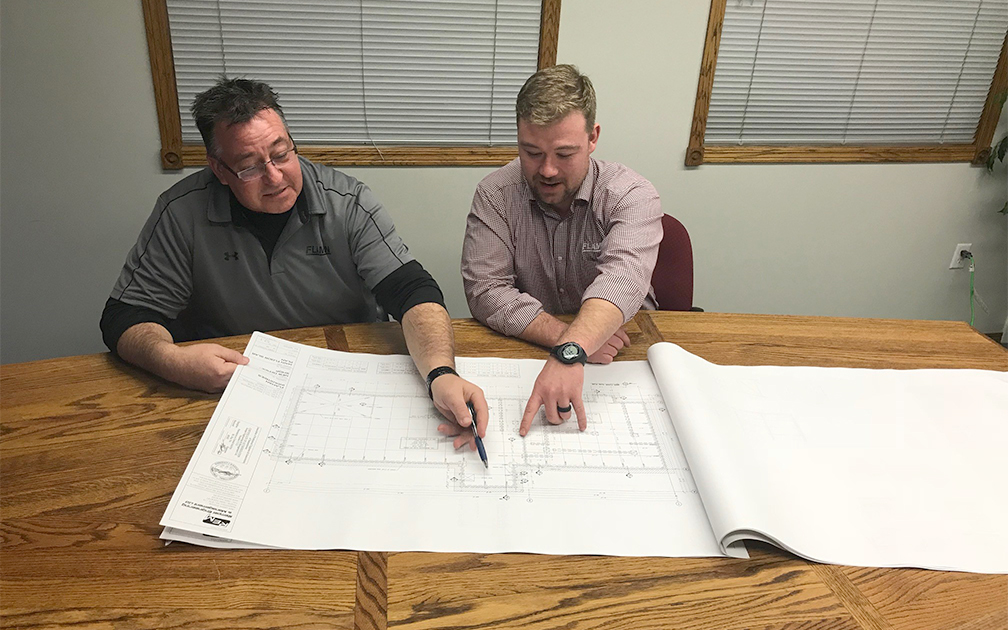

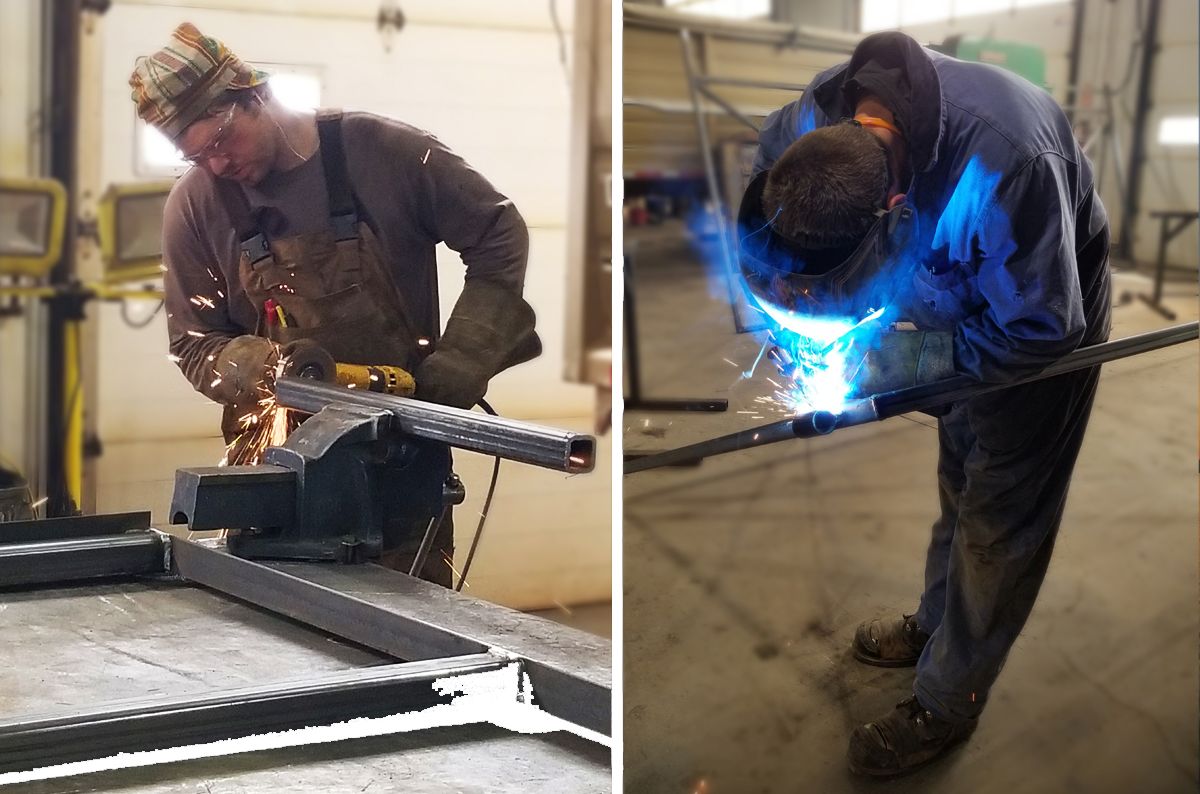

Bin Yard Automation Made Easy with Flaman

Posted by Jeff Brown May 06, 2025

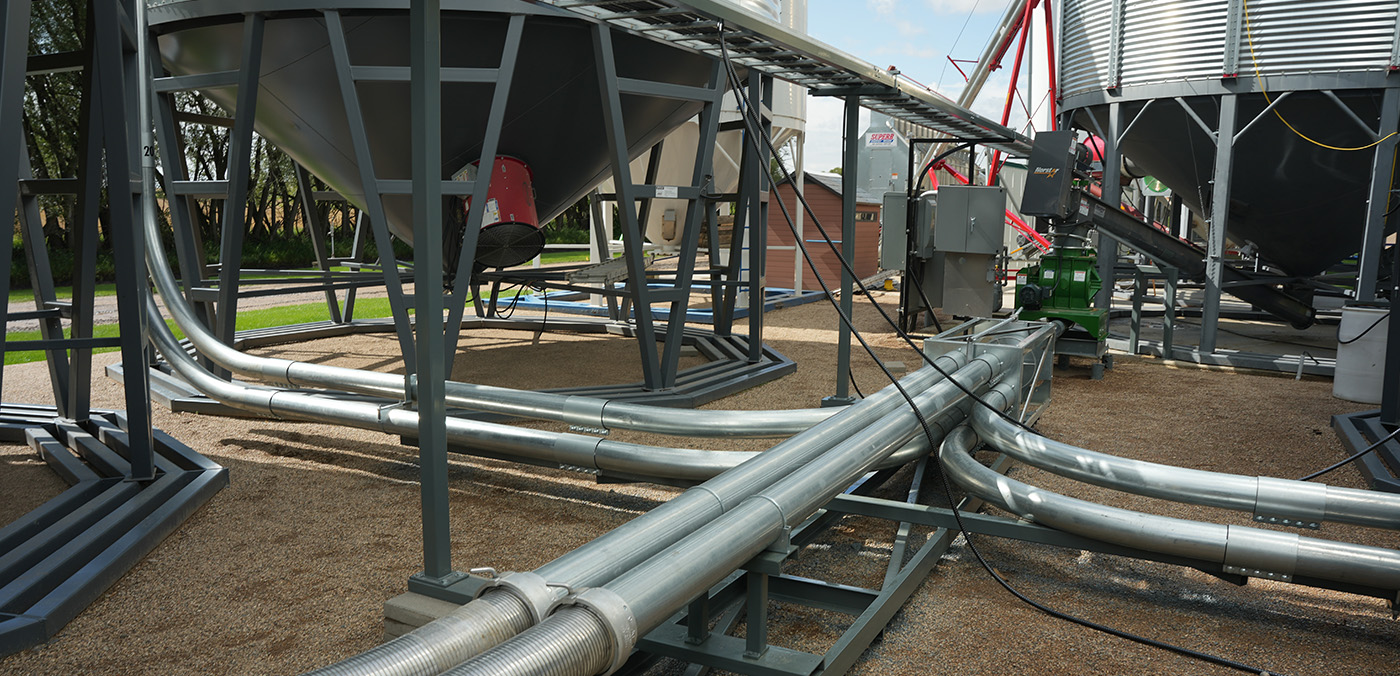

Automation Bin Yard

When customers identify new issues, we pursue innovative solutions.

It's how our Grain Systems team tackled mechanical problems like overloaded grain dryer motors or grain handling systems plugging. Inspired adaptation also helps customers resolve shortages of skilled help and scale bin yard operations with less trouble and expense.

Installing new technology has presented a unique challenge. When farm wiring was more straightforward, a local electrician could handle it while our team installed bins, ladders, dryers, and other equipment. But new complexities can cause errors, downtime, and hours of troubleshooting busy farmers can ill afford.

"We started thinking about solutions," says Grain Systems' Jeff Morrison. "How do we prevent this from happening again? Can we make it simple and repeatable for someone else?" That type of problem-solving inspired our service to make bin yard automation easy, dependable, and accessible to any farm operation.

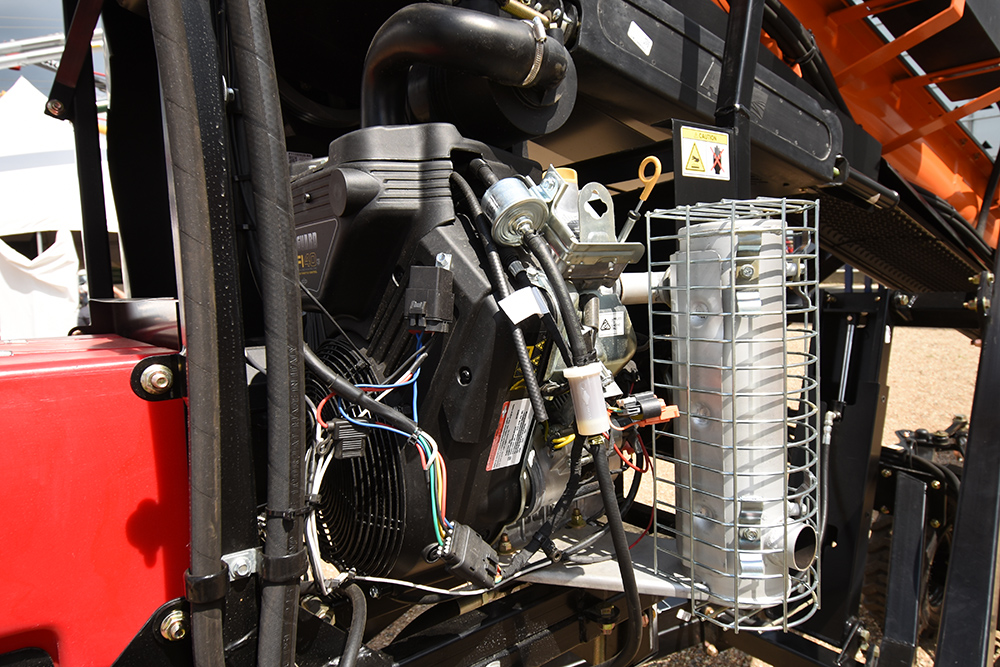

Automation Bin Yard - Dryer Transport Control Cabinet

We developed a pre-built cabinet with all the controls in one place. While this ready-to-go option made wiring safer and simpler, it also reduced installation from two weeks to two days. Customer concerns also inspired automated bin yard solutions like three-phase variable frequency drive (VFD) motors, a complete sensor kit, our new surge bin automator, and easy scalability to facilitate expansion.

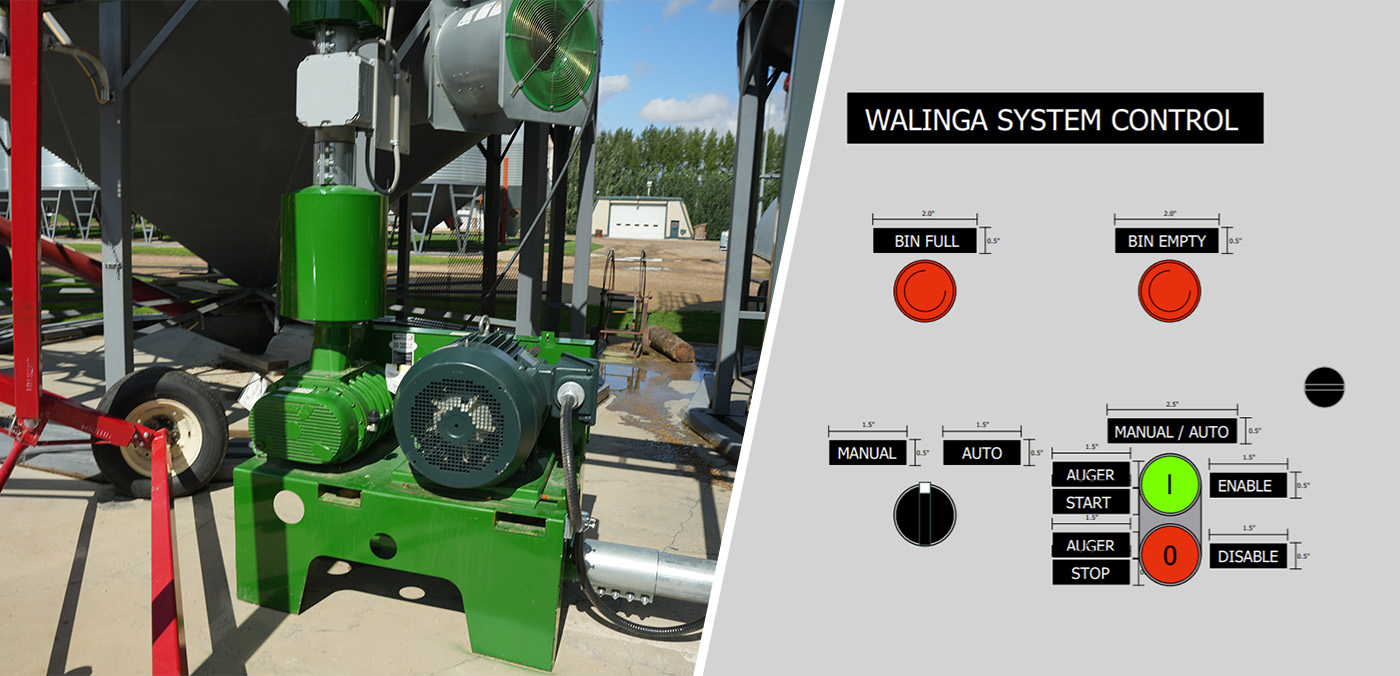

Automation Walinga System Control Cabinet

They all work together in one semi-autonomous system to save you downtime, repair costs, and the hiring of extra help for constant monitoring. And what are farmers saying?

"The funny and beautiful thing about the automation side is if it's working perfectly, you don't hear anything," Jeff says. So, our in-house automation department will keep providing more for them to not talk about.

"We'll take a look at any project. We'll do custom automation. We'll do anything we can to increase the efficiency on your farm to make your life a little easier."

Would you like to know more about what automation can do for your grain operation?

Contact your nearest Flaman location and talk to an automation expert today.

Posted in New Products | More articles by Jeff Brown

Three Ways Drone Technology Can Help Livestock Operations

Posted by Jeff Brown Mar 18, 2025

Drones find and check livestock faster, with less animal stress.

Drones have a lot to offer cattle and sheep operations. Here are three ways aerial observation, quick access to remote areas, multi-level zoom cameras, and thermal imaging can make livestock management much easier.

Keeping Tabs on Your Livestock

On a cold, snowy day, how would you prefer to check your cows?

- Bundling up for a long ground search that ends with you startling your herd and having to search for them again.

- Watching a broad aerial search on your remote control, easily finding your herd with thermal imagery, then zooming in on them from on high while they look up, showing you their clearly visible ear tags.

If you picked 2, you can also progressively lower your drone until your herd get used to posing for 4K video and photos. Accustomed animals are often more comfortable near drones than they are near humans. For this reason, drones are ideal for pen checks. For another reason, you won’t have to spend hundreds of dollars on fuel each week.

Zoom and thermal cameras for less invasive cow-calf observation.

Closer observation is a big help for cow-calf operators. You can use thermal imaging to sort your bred cows from those still in heat. You’ll be able to spot the signs that a cow or heifer is about to calve and observe behavior that tells you others may have trouble birthing. The ability to get close, zoom in, and view high-resolution images gives you an informative window on a cow-calf pair’s progress, with little distress to either animal.

Drones make it easy to check your herd three times a day, so you can catch problems as soon as possible. That’s even more important - and convenient - during winter.

Remote Infrared and zoom imaging reveal health issues early.

Monitoring Herd Health

This precise, non-invasive approach also provides a clearer view of wounds, weight loss, hair loss, labored breathing, sweating, drooling, discharge, or other signs of illness or injury. Your drone can take high-resolution photos you can send directly to your vet.

Infrared cameras can show hidden problems like a sore mouth, heat stress, or developing lameness; bright red heat signatures will indicate the warmth of increased blood flow to affected areas.

Observing animal behaviour can explain problems like poor health, weight loss, and straying. Animals typically bump, butt, or hook to establish a pecking order. Overly aggressive animals can cause injuries or force some animals outside the herd. Grazing alone could also indicate a health problem like mouth soreness and lead to weight loss.

Animal behaviour also speaks to your pasture conditions. You might see animals crowding one grazing spot, which could signal the rest of your pasture needs more seeding, weeding, or fertilization help.

Livestock may also prefer an area closer to a water source, so you can use fencing or mineral and salt distribution to get them chewing elsewhere. Speaking of water sources, drones can be used to read the level of ponds and check for leaking tanks or non-functional pumps and hoses.

Drones don’t just find cattle in dense brush. They also help bring them home.

Herding

A drone’s “eye in the sky” ability to scan broad areas takes the time and guesswork out of locating stray cows or sheep. Thermal imaging can quickly spot animals even in dense brush where human searchers would have great difficulty. Sorting livestock from wildlife is a matter of zooming in or swooping down to check.

You can use a drone to help move them home or to a new pasture, and you don’t have to scare the valuable cow-drone trust out of them doing it. Just swing the drone back and forth behind the herd to “harass,” not frighten, your animals along. Drones also work well alongside herding dogs.

How Flaman Can Help You Add Drones to Your Livestock Operation

Our aerial farming experts can show and tell you more about our available DJI agricultural drones. They can also help you find training and licensing options to pilot your drone safely and confidently.

Call or visit your nearest Flaman location to learn more.

Posted in Uncategorized | More articles by Jeff Brown

How a Rock Picker and Windrower in One Could Work for You

Posted by Jeff Brown Mar 06, 2025

Schulte’s inescapable 1935 is like RoboCop for rocks.

Schulte’s inescapable 1935 is like RoboCop for rocks.

A single rock picker/rock rower unit sounds great, but can it pay for itself? Here’s how the Schulte RW-1935 Spartan Rock Picker Windrower answers that question.

Consider rising repair costs.

“Equipment likes to run, and rocks like to break down equipment. That’s nothing new,” says Kevin Kulak, Flaman’s Territory Manager for Alberta’s Peace Country. “Fifteen to 20 years ago, a rock getting into a combine might cause a few hundred to maybe a couple thousand damage. You mainly lost time.

“But today’s equipment is intricately designed to run quicker with more efficient intake. If the header picks up a rock that goes through the combine, repairs could cost tens of thousands of dollars. They could even reach six figures.”

Doing two jobs at once saves you the extra pass.

More Speed for More Acres

Kevin sees some truth in the idea that bigger, faster, more sophisticated machinery is a response to bigger farms.

“Following seeding and harvesting equipment, rock pickers are getting bigger, wider, and faster. Farmers are looking for more of a quick, blanket approach to more efficient rock picking.”

That’s why Flaman locations, including Kevin’s store in Fairview, offer the Spartan. Its central rock picker is fed by two adjustable side rowers that can widen to 19 feet for quick field coverage. Or they can “wing in” to 16’ to corral heavier rock and net finer rock. You can also adjust a single rock rower for certain field conditions. Working depth settings down to 4.25” can dislodge partially exposed stones.

Bigger high-dump bucket means less rock pile runs.

“A rock rake and rock picker in one that can cover 16 to 19 feet in one pass is easily more efficient than the old way of raking and then going with the rock pickers,” Kevin says. “The other benefit of this rock picker is the size of the bucket- 3 ½ cubic yards, so you don’t have to spend a lot of time going back and forth, dumping. That also appeals to farmers who are picking smaller rocks, just to clear the path for harvesting or baling.”

Appreciable as these time savings are, Kevin still believes the 1935’s marquee feature is protecting your valuable harvesting and baling equipment from damage. It’s built to protect itself, too.

Damage resistance for years of service

Durability and Longevity

Rocks keep coming back every season. So will the Spartan. Schulte’s durable mowers and cutters have won praise from commercial users across North America, and this rock picker/windrower is built to do the same.

Damage-resistant features like hard-surfaced teeth and batt reels safely pick up rocks up to 27” in diameter. A T-iron gate and spring-loaded batts prevent rock jamming, while a hydraulic relief valve system bypasses clots of rocks and dirt until you remove them. It even features a military-grade oil cooler used in Iraq.

Schulte’s designers also addressed hillier terrain, like that found in the Peace country, with a tandem-axle walking wheel system for superior ground following and flotation.

“The settings on this Spartan unit can be set to handle hillsides,” Kevin says. “Not extreme hillsides, but it can handle the majority of land contours we find in Western Canada.”

Where to Find Long-Lasting, Time Saving Protection for Your Valuable Equipment

Call or visit your nearest Flaman location and ask our rock removal experts about the features that make Schulte’s innovative 1935 Spartan a great long-term investment.

Posted in Product Information | More articles by Jeff Brown

Flaman Answers Call for Northern Wildfire Response

Posted by Jeff Brown Mar 05, 2025

Hitting Northern Wildfires with 300 gallons of water and foam.

A lightning strike. A crown fire that jumps from treetop to treetop. Dropping embers fall to the ground and smoulder in a quick-drying peat layer up to five feet deep. They wait all winter to flare up through the forest floor or burn through tree roots and inside trunks. In the northern woods, fire is a different animal.

Tree stands are much sparser on the southern prairies. More people can spot and report blazes, and emergency response is less obstructed. Up north, fires are isolated – usually spotted first by provincial observation systems. Wildland Fire Service responds immediately by air, but high winds can push fires toward remote communities before that help arrives. Volunteer firefighters leave their full-time jobs to form the first line of defense for homes, businesses, infrastructure, and lives.

We have a ready-made solution for these dedicated firefighters and the communities they serve.

QR300 Fire Suppression Skid with cage and without

The Flaman QR300 Fire Suppresion Skid

Our QR300 Fire Skid began as a larger version of the customer-inspired, Flaman built QR150 unit designed for fighting combine fires. Mounted on a flatbed truck or a trailer, the QR300 includes a 300-gallon water tank, a powerful pump and Honda engine, a reel with 100 feet of hose that can spray 35 feet, and a solid Class A Scotty Firefighter Foam-Fast optional cartridge kit that can make water up to 10 times as effective extinguishing flames.

Cage protects tank and provides a rack for tools.

Equipped for Northern Firefighting

Our team modified the QR300 for remote communities, parks, and recreation areas. They added a cage to carry essentials like sprinklers, nozzles, extra hose, a toolbox, and hand tools. The unit has an extra discharge for a 1.5” fire line to boost your wildland grass firefighting and help protect exterior buildings.

The QR300 and its replacement parts are always handy.

More Benefits

The Canadian-made QR300 is designed so most needed parts can easily be retrofitted from materials available at nearby hardware and plumbing stores, saving the usual 6 to 8-week wait for parts from the U.S. or back east.

Ready for new challenges in even more communities

Preparing for the Future

Increasing fire risks are a common concern in Northern areas. First Nations and other communities in Western Canada are keen to learn more about training and equipment like our fire skid. Their requests, combined with a few of our own ideas, are spurring new innovations. Following the Q150’s effective example, we’re developing a 225-gallon fire skid option for fire services.

Considering the changing needs of fire departments, farmers, and other users has helped us make the QR300 more compact, comprehensive, effective, and easy to use.

Learn more about the QR300 and other customer-inspired, Flaman-built firefighting options, available exclusively from Flaman.

Posted in Product Information | More articles by Jeff Brown

How a Bench Custom Grain Cleaner More Than Pays for Itself

Posted by Jeff Brown Nov 19, 2024

It’s a scene that’s played out on farm after farm across Canada. Flaman Sales Specialist James Vanbeselaere positions your input and output augers, sets four levelling jacks, flips a switch on the central electric panel, and another farmer is in business.

If you’ve read our other Bench Custom Grain Cleaners Blog, you know that the business of on-farm grain cleaning makes good long-term economic sense. That blog discussed the savings you could bank, potentially over decades. With James’s help, this one details the ease, versatility, and benefits of operating your own personally customized cleaner.

Easy Start Up

“They usually reach us somewhat assembled, so we can pull it out to the customers already set up to go,” James explains. Very little time elapses between when it arrives in your yard and when it starts running - just enough to complete the wiring and the steps outlined above.

Ease of Use

The first goal of customizing a Bench cleaner is customer convenience. The central electric panel gives users quick, easy-to-reach, and unobstructed access to the Variable Frequency Drive (VFD) controls that govern their intake and output auger speeds.

Customers are also likely to admire the convenient method Bench devised for changing screens.

“The A1door latch system is unlike some cleaners that have grader shells you have to unbolt to take off,” James explains. “You wouldn’t have to do that with an Airens screen.” The Bench method is an easy slide-out, slide-back-in process, as James demonstrates in this video.

Dockage doesn’t stand a chance.

“The Bench 54 by 72-inch portable grain cleaner would probably be our most popular unit,” James says. That unit is equipped with components from another manufacturer, Premier Grain Cleaner of Minneapolis-Saint Paul, Minnesota. Like other Bench models, it does just about everything you could ask to winnow out everything but the top-quality grain you want.

Lighter material is immediately vacuumed away by the Cyclo air system pre-aspirator. Vibrating shaker shoes vibrate the scalp deck, grade deck, and sift deck. Each shoe sits above bouncing balls that help move materials to screens where they either fall through to the next layer or are taken off as dockage. That and a final round of Cyclo aspiration effectively removes everything from straw and rocks to fine chaff.

A Team of Machines

There’s even more you can do to deliver pristine commodities, thanks to Bench’s modular extensions. If you’re cleaning barley, you may want to start with a Bench de-bearder to improve your commodity’s flow-ability going into the grain cleaner - and its test weight afterward.

Once you’ve filtered the impurities out of your grain, you can take out the broken kernels using an indent screen. This screen is wrapped around a rotating drum, using centrifugal force to hold kernels of a desired length in the screen’s pockets while smaller kernels fall off the drum and are taken off as dockage. It’s a popular item, for good reason, as James explains.

“There were some grain cleaners we sold in La Crête, Alberta that had just Airens screens with indents because he’s mainly cleaning wheat. They grow a lot of wheat and canola up there.” Indent screens are ideal for longer-grain crops like wheat, which has been the commodity that creates the most demand for grain cleaning, James says.

Portable Possibilities

Wheat may be the crop most customers want to clean, but Bench provides options for a wide spectrum of cereal, oilseed, and pulse crops. Priding itself on versatility as well as portability, Bench offers cleaning equipment designed to handle barley, beans, canola, chickpeas, flax, oats, soybeans and sunflowers.

Flaman also has its own screen distribution facility in Saskatoon. Like Bench, we offer an inventory that’s carefully selected to take excellent care of the crops you put in your bins.

Kind to Your Commodities. Easy on Electricity.

“It’s a gentle feed,” James says of Bench cleaners’ easy-going stability. Those carefully set levelling jacks prevent a great deal of commodity damage by offsetting uneven terrain, but Bench took its smooth, crop-friendly operation an extra step.

“There are eccentrics underneath that provide a counterbalance,” James says, adding mention of another important benefit: “Once the shaker’s moving back and forth, little horsepower is required to move the tray, because of the momentum. So, guys don’t have to worry about having a big enough power supply to run these.”

Like to Know More about Operating Your Own Custom Grain Cleaner?

Flaman Grain Systems experts are ready to show you in-stock Bench Grain Cleaners and answer any questions you have. Call or visit your nearest Flaman location to discuss effective, economical solutions to your farm’s specific requirements.

Posted in Product Information | Tagged with Grain Cleaning | More articles by Jeff Brown

The Benefits of Customized On-Farm Grain Cleaning

Posted by Jeff Brown Nov 19, 2024

"Every farm’s going to be different,” says James Vanbeselaere. “Every area will be different, depending on what they're trying to clean.” As a Flaman Sales Specialist who’s installed and fired up a lot of customized Bench grain cleaners for enterprising customers, he should know.

What he’s showing farmers is a viable alternative to the transport distances, fuel costs, and unloading cues they can see taking their commodities to seed cleaning plants.

Grain Cleaning Comes Home

“You're just paying an expense to have the other guy clean it,” James says. “A lot of custom cleaners charge about a dollar a bushel. We have customers that clean 10 to 20,000 bushels a year. So, they're spending, you know, upwards of 20 or $30,000 just to have their own grain cleaned. So why not keep that money in your own pocket and put it towards your own system? You'll be building an asset out of it."

That’s why Flaman Grain Systems took the next logical step in the evolution of grain cleaning. It forged a partnership with Great Falls, Montana manufacturer Bench Industries to make on-farm grain cleaning a viable option for more producers.

“That relationship was already formed before I started at Flaman,” James says. “So, I guess I’ve just continued it. They fit our needs. We can sell on-farm units in the right sizes for on-farm use.”

Identifying Your Needs. Formulating Your Solutions.

Bench builds their quality grain cleaners to customer specifications, often using farmer-supplied commodity samples as a starting point. They offer a variety of mobile and mini grain cleaners, plus accessories like the popular Airens screens.

“Bench will do a lot of the customization themselves.” James explains. A customer’s specifically recommended combination could start with a portable or modular air screen machine, mini air screen machine, mid-size grain and seed cleaner, or mobile screen machine and include a vital accessory like a debearder/rethrasher, vibratory conveyor, or separator.

Long-Term Reliability

The tens of thousands of dollars farmers can save doing their own grain cleaning every year can multiply over decades. Flaman has a record of choosing grain cleaners based on their potential long-term durability – choices that have often panned out impressively.

“We’ve got a lot of cleaners that have been around for a long time,” James says. “Twenty, thirty, forty years old. They last.”

“VFD” spells power savings and convenience.

Bench custom grain cleaners feature a frequency drive (VFD) that can reduce power consumption by up to 70%. It’s connected to the electrical panel, a single central point of power connection that gives you speed control over your incoming and outgoing augers.

Nationwide Home Grain Cleaning

Wheat farmers are most likely to take up what Flaman and Bench have to offer. There is also demand for cleaning other commodities. Bench equipment can process other cereal crops like oats and barley, as well as oilseed crops like canola, flax, soybeans, and sunflowers, and pulse crops like peas, chickpeas, and beans.

With Flaman operating its own screen distribution facility in Saskatoon, the two-company partnership can help diverse farming operations across the Prairies – and beyond. We try to be coast to coast, all across Canada.” Wherever they go, these units carry their value with them.

Cost Savings, Care, and Convenience

“We’re pretty competitive in the price range,” James says. But he adds the real economic benefit is the money and time farmers can save. “They’re cleaning their own grain, so they’re not paying for it.”

That’s before a slew of design benefits that make grain cleaning a more pleasant process from the moment your unit arrives on your farm. You can read about them here.

James answers two final questions you might already be asking.

What kind of customer does Flaman believe is a good fit for a Bench custom grain cleaner? With the variety of options Bench offers and the spectrum of commodities and working conditions they can handle, there’s only one answer:

“We’re open to everyone.”

So, how do you find out if a Bench custom grain cleaner is right for you?

“Contact your local farm and sales Rep.”

You can do so by calling or visiting your nearest Flaman location. Our grain cleaning experts will be happy to introduce you to the convenience, benefits, and economy of owning your own Bench custom grain cleaning system.

Posted in Product Information | Tagged with Grain Cleaning | More articles by Jeff Brown

Schulte's Proven Design and Long History of Dependability

Posted by Jeff Brown Oct 23, 2024

When you’ve been around for 11 decades-plus, you must be doing something right. That’s especially true when your manufacturing company started in Englefeld, Saskatchewan and has now won over customers from way down the southern states, who are saying things like this:

“After our company switched to Schulte, our revenue per cutter went up 33%... We think the Schulte cuts better, period. It’s unbelievable the quality of cut that we can get at what we would call a high rate of mowing speed. We get paid by the acre, so productivity is a big deal for us, ground speed is a big deal for us”

- Roman Albert, Owner of Lot Maintenance of Oklahoma Inc., Tulsa, OK

“I cut water levies around the Everglades in Florida and have put this Schulte mower through its paces. It has never let me down and outperforms any cutter I have ever used before. The quality and strength of this cutter is second to none.”

– John Pellicone, Mower Operator, West Palm Beach, FL

There’s only one way to keep your customer base growing and enthused for over a century – continual improvement. It’s something Schulte’s laser-focused on.

Evolving Strength and Features

“The rental department's been working with Schulte mowers, rock pickers and rock rakes since the mid-1990s,” says Ken Barlott, who heads up the Flaman Rentals Department in Nisku, Alberta.

“We've seen the evolution of five different series of mowers and the constant ease-of-use and durability improvements over the years.” He points to Schulte's Series 5 mowers, including the XH1500 “batwing shredder” model, beefed up by the overall weight of the machine with reinforced strength in all the right places.

“The PTO drive line design, including the clutch system, has evolved over the years into a simpler, easier system to work with and maintain onsite,” Ken says. Being in rentals, he’s also duly impressed with the larger rim and higher tire spec, which make transport smoother.

More than Mowers

Flaman also rents and sells Schulte’s likewise durable and efficient rock removal equipment. Meanwhile, an old favourite has been reintroduced to the lineup. Like the manufacturer’s mowers and rock pickers, it’s coming back stronger than ever.

“Schulte was in the tillage business back in the 80s,” Ken says. “Within the last few years, they've gotten back into tillage with their DHX line of disk harrows and a couple other products. The DHX disc harrows have been successful for both our Sales and Rentals departments.

“It's another product they've Built really tough and strong with a lot of steel to be a long-lasting, durable product that that does a good job at the same time.

“It's a pretty crowded market, with a lot of the high-speed tillage tools out there. But. Schulte’s come to offer a somewhat unique disc harrow design that's heavier than most, does a good job and holds up very well.”

Where to Find Schulte Equipment

Looking to buy or rent a mower, rock picker, or disk harrow that’s winning admirers across North America? Our Schulte experts can walk you through the features and durability of the outstanding line of farm equipment. Call or visit your nearest Flaman location to learn more.

Posted in Product Information | Tagged with Schulte | More articles by Jeff Brown

The Benefits that Set Schulte Equipment Apart

Posted by Jeff Brown Oct 11, 2024

Schulte "Batwing" Cutters Provide an Innovatively Narrow Transport Profile.

The equipment that gets the job done. It’s what customers from Florida to Northern Alberta have had to say about Schulte’s line of durable, dependable farm implements. That isn’t by accident, as Ken Barlott can tell you. As Department Head of Flaman Rentals in Nisku Alberta, he has a unique vantage point between Schulte’s product development process and a large chunk of its customer base.

Here are four benefits Ken sees contributing to Schulte’s well-earned international reputation.

1. Built in Canada - and Built Heavy

Schulte industries began in Englefeld, Saskatchewan in the homesteading days of 1912. So, matching the toughness of the ground you're opening is second nature to the company.

Schulte Walking Axles Provide More Stability on Uneven Terrain.

"Just being Canadian-made, the mowers are made for our climate. They're built for our condition," Ken observes. "The thickness of the deck. The transport undercarriage has been modified and beefed up over the years. The hitch continues to be strong and they're definitely not cutting weight in any critical spots like some manufacturers may do to save costs. Schulte is definitely not afraid to keep steel in in their product.

"We work in a pretty tight timeline. When our customers are renting, they want to be working. We want to save them as much downtime as possible to make sure they’re getting their jobs done. So, we need to make sure that we're offering product that'll last. Mowers live a pretty hard life, regardless of what they're doing."

2. Constantly Evolving Product Based on End-User Suggestions.

“I've seen nothing but improvements along the way” Ken says of Flaman’s 30-year relationship with Schulte. “Any issues that have happened along the way have been addressed and improved upon. It's good to deal with the manufacturer that stands behind its product and strives to make them better.”

According to Ken, those changes come from the ground up.

“Over the years, a lot of Schulte representatives have come out with us into the field.” Those reps have also worked directly with end users, demonstrating demo units – sometimes working side-by-side with competitor products – and troubleshooting problems. Issues are identified and questions answered while the equipment is operating in the field. It’s a direct line to end user and distributor observations and suggestions for improvement.

“Complaints are addressed, and the changes are made that will make sense when the equipment is operating in the field,” Ken says. “They're not just a change on paper a CAD design. Customers understand that and like the results that that offers.”

Those results are solid, tangible changes to the equipment’s design and how it operates. Ken cites the change in tire options as a good example:

Schulte Offers Tire Options for Varying Jobs and Field Conditions.

“It may seem like a small issue for some, but a flat tire means downtime or trouble on the side of the road or even in the field.” Schulte responded to customer and distributor feedback by expanding available options. “Previous mowers had two options,” Ken explains. “An aircraft tire or a laminated tire. Laminated was great in the field, but not so great on the road at speed. Aircraft tires were good on the road and okay in the field.”

Schulte expanded its options to include severe duty and forklift style tires, along with a range of transport speeds, price points, and in-field durability flotation levels to cover a wider array of transport distances, uses, terrain, and working conditions. The company also offered configuration options like walking axles with two extra tires per mower.

Customers have liked the changes, and so have rental dealers.

“A change like that is important for us,” Ken says. “It makes doing business easier and more efficient.”

3. Strong Manufacturer Support, Knowledge, and Training

Having Schulte reps out for demos isn’t just market research.

“They’re making sure the end user has a level of comfort with the proper use of the item and that it’s doing the job they want done,” Ken says. They’re also helping customers, dealers, and service departments make sure the warranty process is conducted fairly. “We’ve always felt that they do a good job of that.”

Schulte Field Demos Inform Customers While Providing Valuable Feedback.

To make sure every member of these sectors can stay informed, Schulte’s website offers easy-to-find resources for dealers and the general public alike. These include not only manuals, warranties, and parts, safety, and financing information, but also service videos and docs for mowers, tillage, and rock and snow removal.

“We've had staff watch their training seminars,” Ken says. “And customers, whether they’re custom cutters or MDs and counties, are involved in not just watching those videos, but making them. And they put on sessions on how to maintain their product and really do a strong job of supporting that and making sure that the end user knows how to properly use equipment, fix it, and keep it in good working order. They definitely offer a great level of support.”

4. Quick Access to Parts for All Models

“Parts availability is probably one of the biggest advantages Schulte has over competitors,” Ken says. “At Flaman, we stock a lot of parts ourselves. With Schulte being a Canadian company based out of Saskatchewan, and not far from our Saskatoon location, it's quick to get parts. There's good knowledge in their parts departments with all series going right back to the 90s. So, we can supply parts, support, and service for older mowers, too.

Need Parts? Schulte and Flaman Can Get Them to You, Typically Within Two Days.

“If we don't have something, Schulte has it and they can get a part to us basically within a day or two. A lot of our outlying stores, like up in the Peace Country, can usually source parts through our store here in Nisku. But even if it has to come from Englefeld, it's often a two-day turnaround, maximum. So, it's quite fast to get parts. That’s something I think few other manufacturers and networks can offer.”

Schulte Philosophy in One Word

“If I had to sum it up in one word,” Ken says of Schulte’s relationship with its customers and distributors, “I would say, ‘responsive.’” I've always felt that they listen to their dealer network, they listen to end users. And then they take back that feedback, be it good or bad, and develop their product further.

“I think that’s what separates them from many manufacturers - their process for improving product, training the dealer network and training customers and making sure that everyone's happy with the job and what their units are doing out in the field.”

Where to Find Schulte Equipment

Interested in learning more about Schulte mowers like the “batwing shredder” XH1500, Rock removal implements like the Giant 2500 Rock Picker, or tillage equipment like the Schulte Soilstar DHX Disc Harrow? Our expert staff will be pleased to provide details about this internationally respected line of farm and maintenance equipment. Call your nearest Flaman location to get the conversation started.

Posted in Product Information | Tagged with Schulte | More articles by Jeff Brown

Kwik Kleen Grain Separators. More than Dockage Removal.

Posted by Jeff Brown Oct 07, 2024

When you’re trying to take off a crop in a limited amount of time, there are some things you just don’t want in your bin or your transport truck. Dockage and small seeds from weeds like Kochia or volunteer canola can compromise the condition of your harvest while costing you extra time and money. But there’s something you can do about it.

Removing small seeds will increase airflow, which will speed up your drying time and reduce your risk of heating. Taking out chaff, thin kernels, and other forms of dockage will increase your bushel weight and quality, lowering your transport costs.

Kwik Kleen's high-capacity five-auger 572 and seven-auger 772 grain separators handle these tasks quickly and efficiently. They also help with farming techniques that maximize your land’s productivity.

They remove what you don’t want. The Kwik Kleen system is ideal for separating large and small materials, earning it a reputation for superior dockage removal. It’s designed to separate light product with advanced features for tasks like sizing barley and taking thins out of cereals. This will increase your bushel weight, and lower transport costs, because you’re carrying only the grain you want to ship and nothing else.

They’re made for intercropping. Planting two compatible crops in the same ground at the same time can yield several nutritional benefits. When the time comes to separate them, a Kwik Kleen is well suited to separating large and small commodities like barley and canola, chickpeas and flax, and peas and canola. They’re also helpful if you’re sorting out biproducts for other uses, like dockage for livestock feed.

Cost-effective, high-capacity, and efficient Kwik Kleen grain cleaners excel at dockage separation but can be easily adjusted to perform multiple grain separating tasks.

There’s much more to the Kwik Kleen. Mitch from Flaman walks you through the electrical or hydraulic drive option, available auger sizes, and the variety of screen options available. For more information, call or visit your nearest Flaman location.

Posted in Product Information | Tagged with Kwik Kleen Grain Cleaning | More articles by Jeff Brown

How the Schulte XH1500 Rotary Mower Tames Overgrown Land

Posted by Jeff Brown Sep 13, 2024

When land sits idle for years, it can become fierce to contend with – a tangle of grass, brush and weeds that defies you to make it fertile and productive again. Fortunately, Schulte’s XH1500 rotary mower has stepped up to ably meet the challenge. Now, its latest version makes a seemingly impossible task even quicker and easier.

Schulte features that farmers have come to depend on. The XH1500 was Canadian-made to put the hurt on overgrowth without hurting itself. It’s 3-rotor design conquers tenacious brush with a 7-gauge steel deck, high-torque, self-adjusting clutches, ¼" stump jumper plates, a floating hitch, walking tandem axles, heavy-duty tires, High HP gearboxes, center suspension, and a mower flex arm for steep ditches. Quite an arsenal, but Schulte always aims to do better.

The new Series 5 takes it up a notch. Schulte engineers used airflow testing to identify ways to increase cutting chamber depth and blade tip speed, so farmers could pick up ground speed and get more done. Meanwhile, double chains and half belting over better protection from thrown objects. Series 5 models are also lower maintenance, thanks to thicker, longer lasting nickel-plated pins and fibre-wound interior bushings that don’t require greasing.

No matter how daunting your overgrowth might seem, the Schulte XH1500 gives you the confidence to tackle it.

Let Wayne from Schulte walk you through the Series 5’s innovative new efficiency, safety, convenience, and durability features, including super-suction updraft blades, swing-out hose holder, wing lift cylinder, main section support tower, updated safety lights, scrub-resistant turf shoe design, and various configurations of six or eight 27” skid steer tires.

Visit your nearest Flaman location or shop all Schulte rotary cutters - now at special prices.

Posted in Product Information | More articles by Jeff Brown

Three reasons why a Magnum fuel trailer is worth a second look.

Posted by Jeff Brown May 14, 2024

The more acres you have to till, seed, and harvest, the less time you’ll want to spend refueling. The Magnum Tandem Fuel Trailer and Tridem Fuel Cannon Gooseneck allow you to bring 660 or 1,000 imperial gallons of fuel with you, so you can concentrate on getting the job done. That’s one reason to add a fuel trailer to your farm fleet. Here are three more from our team:

Field Ready. Built to Last.

Our Transport Canada-approved trailers feature durable tanks, solid construction, two-part coating, and 7,000 lb. Torflex axles. They’re more than ready for repeated field use.

Fuel trailers never see good roads. The quality of the Magnum build is impressive. These fuel trailers are rugged and built to last.”

Zane (Swift Current)

Organize Your Tools and Store Essential Equipment.

Our Fuel trailers carry more than fuel. Kevin Heaney of Flaman Southey says you can also find room for other necessities that keep your equipment moving in the field.

“Built to get fuel to the field, they are a well-made self-contained fuel solution that also has great storage options. The cabinet and toolbox options mean you can organize your tools the way you want, keep a needed compressor or generator close at hand, or store parts for your equipment.”

Kevin (Southey)

.jpg)

Size and Budget Options

With its 1,000-gallon capacity, our Magnum Tridem Gooseneck Fuel Trailer can keep three combines and one tractor working. If you don’t need to go big, our mid-size 660-gallon unit is an economical solution.

“The 660-gallon mid-size is a rugged, well-built option that is well-sized for the field. Simple to use, it is a good mid-price option.”

Kevin (Moosomin)

.jpg)

Learn More About Magnum Fuel Trailers

Call or visit your nearest Flaman location and ask our trailer experts to tell you more about the benefits of a Magnum Fuel Trailer. They’ll be happy to discuss available options to create the field-ready trailer you need.

Posted in Product Information | More articles by Jeff Brown

Choose Your Harrow. RiteWay 5 Bar or 7 Bar.

Posted by Jeff Brown Apr 12, 2024

If you’ve heard good things about RiteWay tine harrows, and you’re thinking of buying one, you might be wondering if the HH8200 5-bar or MH7200 7-bar model is right for you.

Both are designed to best serve the needs of customers but in different ways to suit different purposes. Let’s start by looking at the most important working feature of both harrows.

.jpg)

Tines

The five-bar harrows are equipped with 25 28” tines –longer than the 26” tines you usually see in competitor models. The HH8200 offers two tine thickness options – the standard 9/16” or the stouter-than-usual 5/8”. Whichever thickness you choose, you can upgrade your tines with Riteway’s “Max-Life” high-wear edge.

The MH7200’s carbide-tipped tines are smaller than the 5-bar at 24” long and ½" thick, but with two more rows, there are 49 of them – almost twice as many as the HH8200’s 25. They’re also closer together, with only 1.43” of space between them, as opposed to the 5-bars 2.64”. Last but not least, they come standard with the high-wear edge.

Which is better for you? The answer depends on what you need to do with your harrows.

Two Harrows. Two Purposes

The 5-bar model is a heavy harrow, designed to endure tough going. If you stand the harrows straight up, those thicker, more durable tines can dig in like a chisel plow. They can also help remove certain weed seedlings and enhance your herbicide penetration. You can also fill in ruts and level your field, but you may lose moisture doing it.

The 5-bar's main feature is its aggressive approach to crop residue management. It shatters heavy straw for more even re-integration back into your soil. The RiteWay HH8200 excels at raking and disturbing the soil, blackening your field, and leaving a firmer soil pack.

If you’re mission is better trash management, the 7-bar is your ultimate seed bed prep tool. Its more-numerous ½" tines produce more whipping action than the rigid 9/16” or 5/8” of the five-bar, doing a better job of breaking up of your soil’s top crust. You’ll free up more soil absorption, clear the path for plant emergence, and create a more uniform dispersal of crop residue, seed, and chemicals.

More tines, more flexibility, and shallower harrow depth also mean less “down pressure.” Because its down force is more spread out, the Riteway MH7200 leaves the soil less compacted and easier to penetrate. Some users prefer that feature because it allows them to reduce the pressure setting on their seed drills.

Once you’ve decided what kind of field work you need to do, RiteWay offers the harrow to get it done.

Flaman is the right place to find your Riteway Harrow

You’ve just read a few of the features and benefits of the RiteWay MH7200 and HH8200 harrows. There are many more you can discover by calling or visiting your nearest Flaman location. Our tillage experts will be glad to tell you about RiteWay’s heavy-duty construction advantages, its downforce-enhancing parallel linkage system, and more.

Posted in Product Information | Tagged with RiteWay Harrows | More articles by Jeff Brown

You Asked for Diesel.

Posted by Jeff Brown Mar 14, 2024

.jpg)

The Flaman Custom-Build team has finished work on our first Hatz Diesel powered Meridian 12 x 39 Auger. We’re excited to say that the test results have been impressive. Everything ran smooth as silk – operating quietly, while delivering loads of power. So, this Spring, we’ll build more diesel ready Meridian augers and conveyors for our customers.

You’ll soon be able to see them at select stores. For now, we wanted to share our excitement with a sneak peek, along with some of our team's favourite features.

In the words of Curtis Trumier from the production team,

” Every time the conversation comes up with customers about cold starts, the answer is always, ‘We should have bought a diesel engine.’ Well, now they can!”

.jpg)

Cold Weather Start

Engine intake pre-heater and circulating block heater.

"A diesel engine has twice the torque as a gas engine. That’s a huge plus, and the inline-block heater will be excellent for cold-weather starts. Customers tell me their diesel engine will, on average, outlast three-grain augers.

Sheldon Sleeva (Yorkton)

.jpg)

Real Power

24.7 HP Hatz diesel with 90ft/lbs of torque delivers over twice as much torque as a 40 HP gas option.

"My customers have been asking for a diesel option for forever. Gas engines don't like to start in the winter, they blow seals, and bigger augers are underpowered with gas. A diesel option just has more power. This is a unique option at a great price point."

Phil Flaman (Southey)

Robust Auger Frame

A reinforced auger frame designed to handle the weight of a powerful diesel engine.

"For years, my customers have asked for an affordable load-out auger option with a diesel engine. It’s great knowing we can offer this option to customers frustrated with their gas engines. I know a diesel engine will outlast the auger, and I appreciate our build team reinforcing the auger frame for added stability.

Darrell Knash (Yorkton)

.jpg)

No Fail Hand Clutch

Soft start hand clutch for years of bulletproof operation. No expensive electric clutch to fail.

I always get phone calls about the electric clutches quitting. Whether it’s due to the clutch or the soft start module failing, replacing these parts is very expensive. Having the manual hand clutch eliminates all electrical problems and will save money down the road.

Curtis Trumier (Prince Albert)

Our production team in Prince Albert has done an incredible job with our first diesel-powered auger and will begin building more for sale at select stores. Interested in seeing one in action? Contact your local Flaman representative.

Posted in Product Information | Tagged with Meridian Diesel Auger | More articles by Jeff Brown

A Quick Response Solution to Combine Fires

Posted by Jeff Brown Jan 11, 2024

.jpg)

Quick Response Fire Suppression Skid

Combine fires can start in a fraction of a second and burn for up to 30 minutes before they’re noticed, damaging farm livelihoods, and economies. “It seems like every trade show I'm at, every customer I talk to knows somebody who’s had a fire on a combine,” says Ryan Flaman, at Flaman Group of Companies. “All it takes is one bearing to heat up, and those bearings are usually covered in dust or have dust all around.” Combines are often destroyed before a fire truck can arrive, adding callout costs of up to $10K.

Inspiration

Ryan focused on two words, “quick response.”

He sought to improve on the idea of mounting a quick response unit on the combine’s mobile shadow, the grain cart. Flaman already sold tanks, pumps, hoses, and other components they would need. Early in December, 2022, Ryan started envisioning fire protection that was more effective, comprehensive, affordable and accessible than what farmers could rig for themselves. Their input would prove invaluable.

.jpg)

Built-in fork pockets allow you to move the 48” wide skid to your half-ton truck or grain cart easily.

Finding the Right Components

Ryan studied available options and reviewed them in meetings with the Parts and Hardware department throughout the winter. There were units powered by rechargeable 12-volt batteries. Other small electric units offered a 35-gallon tank. Gas-powered kits offered 60 US gallon tanks and either mounted on grain carts or sat in the back of an RV or pickup truck. But many farmers were asking for more spray volume.

.jpg) A 150-gallon tank that fits neatly out of the way on a grain cart.

A 150-gallon tank that fits neatly out of the way on a grain cart.

Unfortunately, 250-gallon tanks took up too much space and weighed up to 3000 pounds with the necessary mounting hardware. The customers he talked to had their own number in mind – 150 Imperial gallons or 180 US gallons. The closest Ryan could source were 125 gallon tanks.

That tank was part of a prototype Ryan showed to his uncle Don Flaman. Don was excited, but Parts and Hardware thought they could come closer to the volume customers had asked for. So, they had a tank molded that could hold 150 gallons and fit neatly out of the way on a grain cart. It’s a uniquely Flaman component, unavailable any place else.

The skid plate was a slightly different story. Ryan had envisioned a hanger system to hold the unit from the top, but he needed a strong plate underneath that could support everything and be compact enough to fit in a tight space. This would also make it easy to transport and store. He scribbled the dimensions on a napkin diagram, scanned it, and sent it off to an engineer. That began a process of back-and-forth tweaks, honing a skid plate that met all the necessary criteria.

.jpg)

3/16” powder-coated steel skid. Ruggedly built to handle heavy use.

The final skid plate uses 3/16” thick metal, protected by Powdercoat. Similar products settled for a 1/16” thickness can be squished even flatter when the bolts are tightened. The Flaman skid also features fork pockets, so it can be easily moved to your grain cart, the back of a pickup truck, or any storage space when not in use.

.jpg) Cost-effective, reliable, and user friendly cartridge based foam delivery system.

Cost-effective, reliable, and user friendly cartridge based foam delivery system.

Fire Suppression

Next, Ryan and the team looked at fire-suppression foam. Direct-injection liquid foam systems seemed promising. Their foam mixing system was ideal for several home applications, but was it right for Flaman’s new firefighting unit?

Liquid foam has a limited shelf life, and it requires agitation once a month. With harvest coming once in a busy farm year, it was easy to forget the monthly maintenance. Ryan didn’t want his customers depending on something that had any chance of failing them at the exact wrong moment.

So, he opted for a solid foam cartridge system that restricts water flow. This creates more back pressure, so the stream can spray farther and hit flames harder. The cartridges don’t require shaking or have a predetermined expiry date. You can keep them in your pickup’s glove box until you need one.

.jpg) 100 feet of 3/4 inch 150 PSI hose on an industrial cox reel

100 feet of 3/4 inch 150 PSI hose on an industrial cox reel

Reliable Hose Access

Other firefighting units Ryan has seen have opted for clear air seeder (PVC) hose looped around two small hooks, which looked likely to tangle up at the worst possible moment. The Flaman Firefighter uses a black rubber hose rated at 150 PSI and spooled around a trusty Cox hose reel. Ryan chose it because it was compact, well-built and able to hold 100 feet of hose – putting plenty of reach in a small space.

.jpg) 2” Aluminum Pump with Honda GX200

2” Aluminum Pump with Honda GX200

The Pump for the Job

“The only thing that we readily had in stock was the pump,” Ryan says. The popular BE WP-2065HL general purpose water pump was ideally suited to the job. Equipped with a cast-iron impeller, it’s lightweight. Powered by a Honda GX200 Engine, it has the power to go all day every day.

But will it work?

After a winter of planning and assembling all the components, the team took the prototype out for field testing. To everyone’s gratification, there was no need to adjust its operation.

“We took the prototype number one and filled it up with water and throttled it up and water would shoot like 30 feet,” Ryan says. That’s some heavy pressure, but you’ll have a good 20 minutes of continuous flow without draining your tank, thanks to constriction at the nozzle.

The only necessary changes were to the tank's shape and the width of the skid. Those alterations made, the Flaman Firefighter was ready to report for duty – or more correctly, duties.

.jpg) Built-in fork pockets

Built-in fork pockets

More Uses than One

The Firefighter may be designed for combine fires, but its quick response capabilities lend themselves to other emergency applications, like grass and brush fires. Mounted on the back of a pickup truck, it can provide a first line of defense for more remote communities.

Value for Money

“I looked at what customers could get and what they would have to pay for it,” Ryan says. “I figured we could give them something better at a more affordable price.” That took a lot of planning, shopping around and testing, but the end product delivered the safety and functionality the customers wanted at the right size and price.

“Our customers’ feedback identified the issues we needed to address. They asked us to deliver a bigger tank, a heavier skid, a pump with a bigger motor, and a hose reel that’s compact but still heavy-duty. They answered the question, ‘How can I make something better?’ I think I made more work for myself than I needed to, but I’ve enjoyed this.”

See the Future of Farm Firefighting at Your Nearest Flaman Location

The Flaman Quick Response Fire Suppression Skid is one of many farm, home and business safety solutions we offer. Drop by and see this Inhouse-designed unit at any of our seven Flaman Sales locations in Saskatchewan and Manitoba.

Call or visit your nearest location – Swift Current, Swan River, Prince Albert, Saskatoon, Southey, Yorkton, or Moosomin. Our fire suppression experts will be happy to show you the many features that could make all the difference one day.

Posted in Product Information | Tagged with Combine fires firefighting Quick Response Fire Suppression Skid | More articles by Jeff Brown

Three Phase Electricity for Grain Handling

Posted by Jeff Brown Nov 06, 2023

Three-Phrase Grain Handling Power. Doable. Valuable.

More acres seeded might mean more bushels brought into your bin yard. But it doesn't have to mean more work and expense. As farming grows, new technologies emerge to boost your grain operation's speed and efficiency.

Technology Boosts Productivity.

Grain Dryers like our AGI NECO and Oakland models are designed to run continuously and safely. There's no need for you to spend your time or hire a hand to supervise them. And with remote monitoring systems, you can spend more time working in the field.

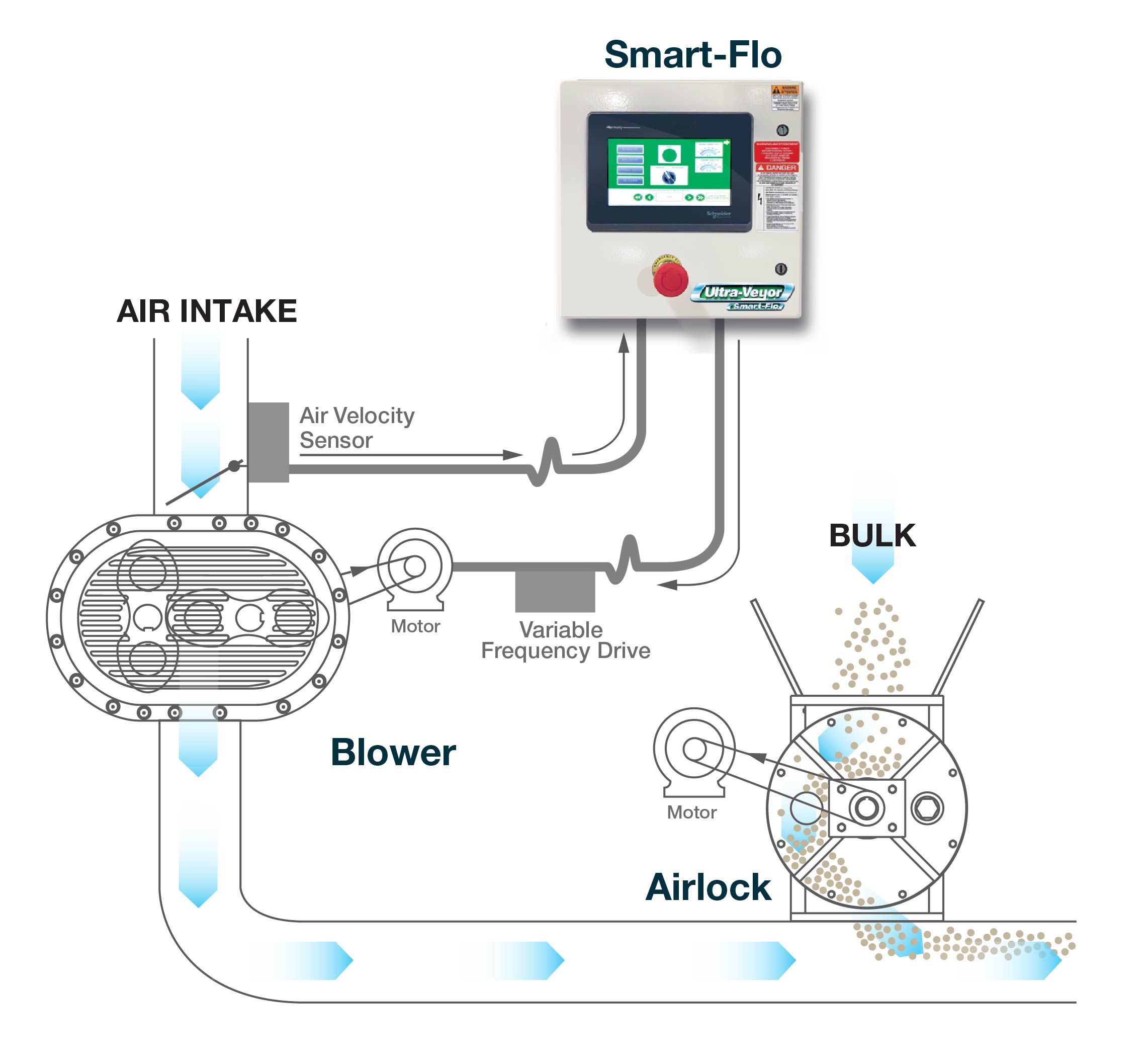

The same goes for the Walinga Blower System. Its airflow can move dried grain to your dry bins at rates of up to 2,000 bushels an hour. Achieving those higher volumes depends on the size of your piping and your motor's horsepower. The latter can be a sticking point for many farmers.

Amping Up Your Operation

Most farming operations are still wired for single-phase power. The high-volume systems mentioned above require three-phase power, which hits its peak amplitude three times as often as single-phase for three times the power output. It’s the optimum circuit for power generation. Higher-phase systems prove too complicated and expensive to be worth pursuing.

Despite its benefits, Farmers aren't often eager to rewire their farms to facilitate three-phase. Fortunately, they don't have to.

How to Convert from Single to Three-Phase Power Safely and Affordably

Walinga Blower Systems and AGI NECO and Oakland grain dryers all employ VFD technology. Variable Feed Drives have two outstanding features. First, they allow your motor to slow down and speed up, limiting energy consumption to reduce your power bill.

Walinga's Variable Frequency Drive Systems monitor and automatically adjust motor speeds

Walinga's Variable Frequency Drive Systems monitor and automatically adjust motor speeds

More importantly, they can be set up to draw current from your existing single-phase power source and convert it to three-phase electricity. So, you don't have to change your farm's entire power supply to run one or two bigger machines.

It's worth noting that not every variable frequency drive motor can deliver these results, but AGI, Oakland, and Walinga have engineered their motors with the farmer's single-phase/three-phase dilemma in mind.

Savings and Convenience to Help You Get Growing

There’s a big benefit to this small-scale phase shift. It removes a giant obstacle to building up your bin yard. Instead of waiting until you’ve saved up for a big change, you can increase your grain handling capacity in stages. More high-quality grain in your bin allows you to purchase more components down the road.

Ready to Lower Grain Handling Electricity Costs and Boost Production?

Get in touch with your local Flaman dealer and ask our bin yard experts how you can convert single-phase to three-phase power, add valuable components, and get your bin yard humming.

Posted in Product Information | Tagged with grain handling three phase power walinga neco oakland | More articles by Jeff Brown

Farmer-Approved Moisture Testing from Perten

Posted by Jeff Brown Jul 11, 2023

In agriculture, nothing is ever absolutely certain. However, farmers who’ve used the Perten AM 5200-Farm Moisture Meter say its instantaneous accuracy comes impressively close.

“When you have so many different people around - four different people using it - it was nice not to use the scale,” says Bruce Elke of Jansen, Saskatchewan. “Everybody puts it in and gets the same result.”

Bruce Elke shares the benefits of the Perten 5200-Farm

It’s not the first moisture tester to have its accuracy praised, not even the first one Bruce has praised. His previous tester was also bang-on, but the 5200-Farm brings something extra to the table. “I think really it was the ease of use and just taking out the possibilities of error,” he says.

“Customers like that,” observes Shaun Gettis, Vice President of Sales at Flaman. “No need to weigh or take temperature tests.”

A Simple Process

For a machine that delivers precise moisture reports for various grains, oilseeds, pulses, beans, lentils, seeds, and more the 5200-Farm is a breeze to operate.

Just select the grain type you’re analyzing from an extensive onscreen menu showing virtually every type available in North America. You can then enter ID info for your sample, saving your bin number, test date, and time for future reference.

-2 Edit B copy.jpg)

Then scoop your sample in until the 5200’s cup is full and click GO. The tester intuitively takes the prescribed weight it needs and removes the excess. After a 25-second analysis, your sample’s moisture, bushel weight, and temperature all show up on the 5200’s colour touch-screen display. Every kernel in the machine drops into a clean-out drawer for easy removal. Need to do another sample? Just hit NEXT.

“There was no chance of finding the wrong page in the book or using the wrong weight and having mistakes made,” says Bruce Elke. “That was one of the things that I really liked.”

Reliable Readings. Customer Confidence.

The moisture curve remains accurate throughout a wide range of temperatures. That’s critical for farmers drying grain or harvesting on hot days. Not surprisingly, it’s one of the benefits potential users are most curious about.

Some have seen the Perten 5200-Farm at work in their local elevator. Others have had a Flaman rep bring one out to their farm to demonstrate the tester’s advanced accuracy sampling their own grain, and the response has been positive.

Ask your local Flaman sales rep about an on-farm demo

“Farmers like that the test data is logged,” says Shaun Gettis. “The bushel weight gives them more insight into their grain.” That, along with consistent, reliable moisture testing results – even in extreme temperatures – allows producers to make their combining and grain drying decisions with confidence, which is value for money.

Experience Perten AM 5200-Farm Accuracy at Flaman

Call or visit your nearest Flaman location to discuss how the 5200 can give you confidence in your crop’s readiness. Talk to a moisture-testing expert at any of our 11 locations across Manitoba, Saskatchewan, and Alberta.

Posted in Product Information | Tagged with perten grain analysis moisture testing | More articles by Jeff Brown

Five Reasons to Upgrade Your Grain Handling

Posted by Jeff Brown Jun 20, 2023

Wish managing your bin yard was a little less complicated? A tied-in grain-handling system can make that happen. Flaman offers several innovative components that can eliminate the effort, expense, and inconvenience of getting your grain safely in your bins. Bringing them together in one place yields a bumper crop of benefits.

1. Reduce Manpower and Save on Labour Costs

Consider all the moving parts involved in traditional grain handling – augers, tractors, and semis to drive in and unload, plus the manpower to keep them moving. Setting up a grain handling system can save you the time it takes to move and operate equipment plus the expense of hiring help.

Options like belly dumping or side dumping grain into a pit that feeds a bucket elevator can be done by one person – saving you a lot of hiring, hollering, and hand signals.

2. Minimize Maintenance Costs

You’re probably all too aware of the cost of running a tractor back and forth to your grain bins. In addition to fuel, extra operating time will also mean more wear and maintenance. Your auger flighting can also wear out, suffering more metal-on-metal damage as time goes by.

A self-propelled, belt-driven bucket elevator is designed to avoid impact points, and a pit system can eliminate the need for a tractor to move or power anything.

copy.jpg)

3. Eliminate Seed and Grain Damage

Of course, if metal can damage metal, it can easily crush any seed that gets caught between an auger’s flighting and its tube. Brittle pulses like lentils and peas are particularly vulnerable to significant and costly damage.

A gentler handling option makes good economic sense. You could employ a low-cost Hutchinson Chain Loop system, operating like a sideways-mounted bucket elevator, or you could opt for the bucket elevator itself, which carries your grain in plastic buckets for minimum damage.

Walinga’s air system takes seed and grain protection even further. Its vacuum intake and blower combo gives your crop an air-cushioned ride to the bin.

4. Invest in the Future Growth of Your Operation with a Staged Expansion Approach

Not everyone can afford to set up a state-of-the-art grain handling system on day one. Fortunately, Flaman can help you structure a budget-friendly plan to expand your grain operation whenever and however you feel comfortable.

You can build up in stages over a number of years. For instance, Stage 1 might mean setting up a reliable bin-and-auger process. Your second stage might include tying all your bins together with a grated pit and bucket elevator system. In stage 3, you might add grain storage or introduce a truck scale or an overhead unload bin you can drive your truck under. Your fourth stage might see the addition of cleaning and processing equipment.

This is just an example. You could switch it up to expand your operation as you see fit. Every customer is different, and Flaman helps each one find an individual solution.

5. Increase Efficiency

Nothing saves time and money like speed and volume. Flaman offers both. Our low-maintenance grain handling equipment is proven to provide a high degree of safety for your crop and yourself. These include grain-moving options with impressive capacities of up to 20,000 bushels an hour.

From Start to Finish, We Have It Handled