Flaman Rentals Blog

RSS feed

Categories

Recent activity

- What's it like being a Flaman Rental Dealer?

- A Brief History of the Newest Flaman Store in Swift Current

- Disney's NEW Leadership Excellence Training Course

- Disney's Approach To Quality Service

- Disney's Approach To Quality Service

- Trailering 'Rules of the Road' Updated

- 10th Annual Frank J. Flaman Foundation Gala 2016

- Why Frank Cares

Authors

Archive

AGI Batco UCX3 Conveyor. U-Trough Convenience. All Commodities.

Posted by Jeff Brown May 08, 2023

We could speak volumes about the volumes the all-commodity AGI Batco UCX3 U-Trough Belt Conveyor can process. It’s powerful, high-capacity, and fast. In ideal conditions, it can move up to 12,500 bushels (about 340 tons) of canola in a single hour.

At that rate, it’s not sheer fantasy to imagine loading a Super B in 10 minutes. Even heavier crops like wheat and peas still whistle through at about 10,000 BPH.

Fast as that ride might be, the cereals, pulses, oilseeds, or fertilizers you put through it come out hardly the worse for wear. Gentle handling is the beauty of a U-trough system – especially one with the UCX3’s problem-solving design. It focuses on eliminating points where spillage, crushing, and other damage can occur, from intake to spout.

Advanced Leakage Protection

That starts with the redesigned collapsible hopper. It’s built low, so you can be sure it will fit easily under any bin. The new, reinforced design also maximizes grain flow by minimizing potential leakage and grinding along its sides.

A double-lip sealed edge keeps your commodities tightly in place as they travel up the conveyor’s 15” Direct X belt. It’s a U-trough-ready update of the chevron pattern used in the successful AGI Batco BCX3 tube conveyor.

Sticking With What Works

The BCX3 design worked so well that many of its features have been incorporated into, or adapted to, the UCX3. These include:

Turbo clean wash system, two belt scrapers, and belt brush. Working together in one remarkably easy clean-out process, they keep your belt debris-free and oilseed-friendly.

Redesigned S-Drive. Easily adjusted with normal tools, this feature keeps your belt running straight and true without the risk of overtightening your pinch-roller bearings.

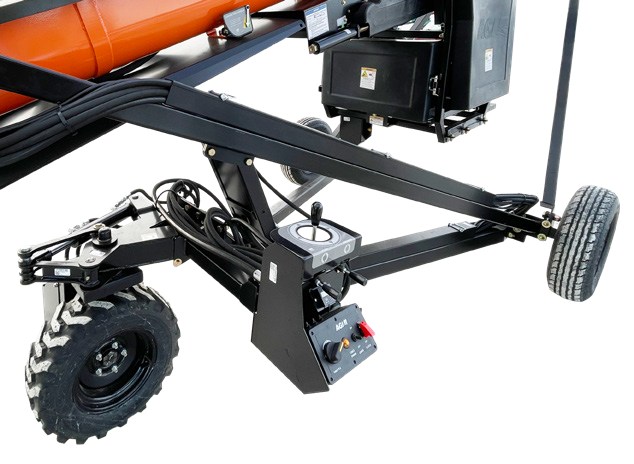

IBEX Mover Kit. Redesigned with a built-in braking system and a 160° turning radius, the IBEX is powerful and easy to maneuver whether you’re on a flat, dry surface or navigating deep muck. Two features provide the outstanding traction you’ll need to get you through a rain or snow-drenched day in your bin yard: Skid steer-style tires for better traction and single-wheel drop-and-go convenience and balance.

More Power to U.

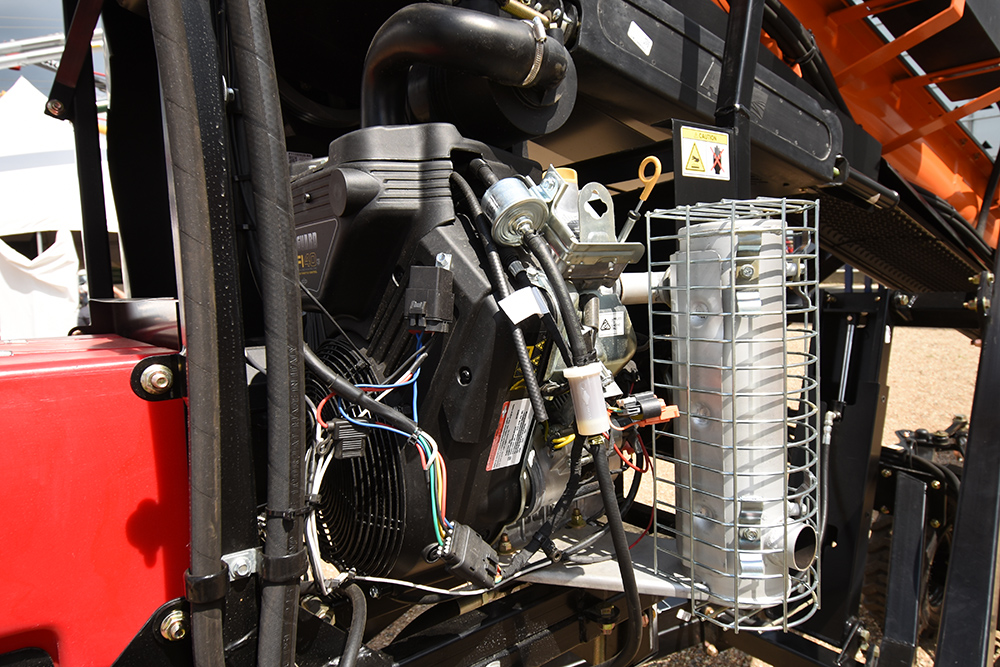

One notable difference between the U-Trough Conveyor and the BCX3 is the size of their engines. The BCX3 offers a choice of two gasoline engines – the 32HP Kohler or the 33HP EFI Vanguard. The UCX3 bumps the power up with a 40HP EFI Vanguard motor and upgraded drive components to further increase hydraulic performance and longevity.

Learn what the UCX3 can do for you at Flaman.

Want to know more about the AGI Batco UCX3 U-Trough Conveyor? You can find expert advice at 11 Flaman dealers across Manitoba, Saskatchewan, and Alberta. Drop by your nearest Flaman location and get an up-close look at features like the ergonomic command centre, IBEX Mover Kit, and spillage control.

Ask our knowledgeable sales staff how the UCX3 or any of our other equipment can help your farming operation.

Posted in Product Information | Tagged with agi batco u-trough conveyor belt oilseed | More articles by Jeff Brown

When the elevator calls on a cold day, will your auger be ready? Take these tips for a dependable cold weather start

Posted by Mitch Flaman Feb 11, 2021

With the cold weather snap we've been having, I'm reminded that my dad always said, "Things just start breaking down and don't work well after -25". That being said, you don't always have the luxury of taking a day off when the elevator calls for grain in the middle of winter. In case you're in a rush and it's too cold to fire up the auger to load the trucks, take a few minutes and remind yourself of a couple of key tips to ensure that your auger or conveyor starts when you need it to..jpg)

Fuel

Fuel problems always seem to show up when the cold hits. The two most common fuel problems are:

1. Old/dirty fuel

2. Water in the fuel

Make sure you are always using good clean fuel. Check your fuel filters often, and replace them when necessary. It's the easiest way to ensure the auger engine will start easy and run clean at a cold, crucial time. The last thing you want when you're in a rush is pausing to clean the carb or rip the engine apart. If you're not sure how old the fuel is in the jerry can you're about to use, you're better off using it for a bonfire. Go get some new stuff and prevent the headache.

Water in fuel is as bad as dirty or old fuel, and sometimes worse. Because water is heavier than fuel, it will usually find its way to the bottom of the tank, often where the fuel line feeds the carburetor. And you can be sure that it will either freeze up when it's cold or prevent the motor from igniting when you need it to most. If there is a drain valve on your auger, it is recommended you periodically drain the fuel in the spring or when the unit is warmed up in the shop. Fuel additives such as Sea Foam or isopropyl-based gas line antifreeze can also help mitigate the problems old or water-based fuel can pose on engines.

EFI vs Carbureted EnginesMost farms have augers or conveyors with both carbureted and EFI (electronic fuel injection) motors. Although they operate very much the same, the starting procedure may differ.

On a carbureted engine, add a small amount of throttle to ensure the engine will idle, pull the choke fully out and start to crank the motor over. Be sure not to over-throttle and flood the engine. Once the motor fires and runs for a few seconds, you can usually push the choke in half-way and let the engine warm-up for 5-15 minutes. After the engine is good and warm, you can push the choke in all the way and you should be good to go.

When cold starting an EFI engine, there are a couple other things to consider. Set the throttle to approximately one-third open (between idle and one-half throttle), turn the key on, and watch for any lights on the control panels. This will ensure everything is powering up. Listen for a humming sound to confirm the electric fuel pump is working. After the pump kicks in, fully turn the key to the start position and start cranking the engine over. If it stalls or does not start after a few seconds, cycle the key to the off position, and repeat this step. Wait for the electric pump to kick in again and start cranking the engine over. This may need to be repeated multiple times. Once the engine is idling and running, allow 5-15 minutes for it to warm up before putting any load on it.

Following the tips above will ensure you the best chance of making sure your auger/conveyor starts in the cold weather. Sometimes it is just too cold for an engine to start regardless of what prep work you do. In that case, it might be time to go inside where it's warm, and browse here for a new auger with modern technology and new, clean fuel in the tank!

-----

For more information on our grain handling equipment, auger accessories, or to learn more about cold starting an engine, talk to one of our agriculture specialists at your nearest Flaman location.

Posted in Product Information | Tagged with auger conveyor engine EFI carburetor cold start | More articles by Mitch Flaman

Three reasons the Batco BCX3 needs to be your next conveyor

Posted by Mitch Flaman Jan 21, 2021

It’s here. The legendary orange “gentle giant” from AGI/Batco has received more than a facelift for 2021. After a complete redesign from hopper to downspout, the BCX3 conveyor has a few new features worth bragging about. Aside from the redesigned S-Drive, new Turbo-Clean Wash System, and remodeled fuel tank, there are still 3 big upgrades that make this the most versatile conveyor yet.

- Move All Commodities - Most notably, the biggest feature of 2021 is the BCX3 conveyor’s ability to move all farm commodities - that’s right, INCLUDING CANOLA. Gentle on pulses, quick on cereals, and capable of oilseeds, you now have one tool for all your jobs. This has been made possible with a redesigned hopper & downspout, plus the new Turbo-Clean wash system with multiple scrapers & brushes. As with the use of any oilseed, additional maintenance and cleaning is required to ensure the longevity of your conveyor.

- Multiple Controls, One Location - Redesigned, with functionality and safety in mind, you will find all the controls in one location. This means you can adjust the throttle, engage the clutch, change the height for both hopper & discharge, and drive all from one spot. No more reaching. The conveyor’s control center has been relocated to provide better ergonomics and visibility as you drive, as well as additional clearance when setting up underneath your hopper.

Ergonomic Command Centre

- Move with Ease - A completely redesigned mover adds substantial traction and maneuverability for your conveyor. The new all-terrain tire design has been coupled with an internal braking system to prevent rollback. The drop-and-go design is simple and safe - no more engaging or locking hubs. The drive wheel has been relocated to better utilize the weight distribution of the conveyor. This adds strength and exceptional traction. Did we mention the increased turning radius? The new mover design offers unparalleled maneuverability and versatility.

Redesigned Mover Kit

You need to see it to believe it.

For more information on our AGI Batco BCX3 conveyors, talk to one of our ag specialists at your nearest Flaman location or give us a visit and we would be happy to show you what all the buzz is about! We may even let you take it for a spin. Even with winter conditions, we can assure you that you won’t need to worry about getting it stuck!

Posted in New Products | Tagged with conveyor Batco BCX3 grain handling | More articles by Mitch Flaman

Move your grain with the all-new AGI Hutchinson Double Run Chain Conveyor

Posted by Paul Boechler Sep 14, 2020

The AGI Hutchinson Double Run Chain Conveyor is a brand new product to the Flaman lineup. It is built in Western Canada with the prairie farmer in mind. Manufactured at AGI’s plant in Swift Current, SK, it is designed to handle delicate crops grown on the prairies, like pulses, far more gently than an auger would.

The UHMW plastic paddles gently convey grain

Maneuverable in Tight Spaces:

Modeled after the clean grain elevator on your combine, its UHMW plastic paddles convey crops to your bin in a gentle manner. A huge benefit of this is the ability to operate at full capacity from nearly any angle, fitting into tighter spaces.

Another feature of the Double Run is the easy to use swivel arc kit, which makes the unit highly portable around the yard. You can move it from bin to bin or dryer, by simply swapping a few pins.

The swivel arc kit allows for easy maneuverability

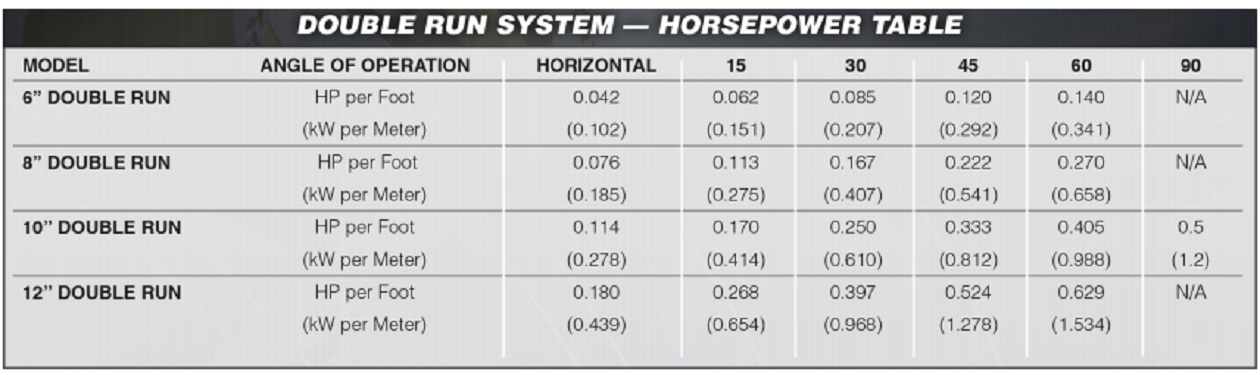

Low Power Requirements:

While the Double Run is powerful in getting your grain into the bin, it has a low horsepower requirement compared to alternative grain handling equipment. As an example, 8” model with a length of 82’ requires just 18 HP at a 45° angle (see chart below). These units are available with an electric motor or PTO drive, giving you plenty of power options.

Proven Reliability & Longevity:

We all know an unreliable auger can be a huge problem for your operation at harvest time. The Double Run was designed as a solution to this problem. The chain conveyor requires less maintenance and has more longevity than your typical auger. Keep the chain running straight and tensioned properly, and these units will just run. And run. And run.

Travis Frey of AGI walks us through exactly what makes this unit different:

The Double run comes in lengths of up to 82’ on the 8” and 10” models, with up to 4,000 BPH capacity on the 8” and 6,000 BPH on the 10”. It is also available in a 12” model, which has a 10,000 BPH capacity and lengths up to 130’.

Stop by your local Flaman Ag store or give us a call for more information on this unit.

Posted in New Products | Tagged with AGI Hutchinson Double Run chain conveyor grain handling grain systems Flaman | More articles by Paul Boechler

Move your auger or conveyor safely with the Lift-EZ Hydraulic Jack

Posted by Jennifer Thompson Jun 30, 2020

If you’ve ever moved grain with a conveyor or auger, you know that standard screw jacks can be inconvenient and a hassle to hook up and connect with your tractor. And if you’ve ever said to yourself “there has to be a better way,” then you’re not alone. The Lift-EZ Hydraulic Jack is a safe and convenient way to connect your auger or conveyor to your tractor

We spoke with the product’s inventor, Bret Watson, the operations manager at Flaman’s Swift Current location, about where the idea for this product came from, and why every farmer could use one.

Tell me where the idea for this hydraulic jack came from?

Bret: I invented it two years ago with Bob Schafer. Bob has a service company that deals with farmers, and his customers were having trouble with their jacks getting damaged. They needed another option.

Bob and I were having coffee one day and we said to ourselves, “this is something we could do.” Bob is a mechanic by trade, and I have an engineering degree and manufacturing background. Hydraulics are readily available on back of a tractor so that’s why we chose that route.

What was the creation process like?

Bret: We started with some drawings on a piece of paper, then I used CAD to develop it and make a prototype. Then we fine-tuned it to make sure it was user-friendly. From concept to completion it took about 3-4 months.

Tell me about the jack and what makes it different.

Bret: With this jack, the farmer can back up to auger/conveyor, connect the jack hoses and then safely lower/raise the unit from the cab of his/her tractor. They can easily get everything aligned, then slide in the implement pin, raise the Lift-EZ jack and then they’re good to go. It uses the hydraulics that tractors already have, so it’s easy to add on. I haven’t seen anything like this for farm use before.

Tell me about the added safety features of this hydraulic jack.

Bret: The jack comes with a hydraulic safety valve, so if there is any damage to any hydraulic hose the jack won’t come down. You can adjust the jack from your seat safely. When you get out of the tractor, you don’t have to worry about the jack creeping down, the valve locks it and won’t allow it to come down unexpectedly, which of course could be very dangerous.

Can this jack go on any auger or conveyor?

Bret: Yes, it can be retrofitted to any auger or conveyor. The jack stub can be mounted at any height in order to replace any standard screw jack. It’s very user-friendly.

What inspires you to invent products like this?

Bret: I’m driven by solving problems and safety. This product came right from a farmer’s need. It’s a safer product and something that will help them.

The Lift-EZ Hydraulic Jack will be available at most Flaman locations in Saskatchewan. Please call your local Saskatchewan store to ask about availability or to speak to a product specialist.

Posted in Product Information | Tagged with jack hydraulic jack auger conveyor safety | More articles by Jennifer Thompson

Locations

Locations