Flaman Rentals Blog

RSS feed

Categories

Recent activity

- What's it like being a Flaman Rental Dealer?

- A Brief History of the Newest Flaman Store in Swift Current

- Disney's NEW Leadership Excellence Training Course

- Disney's Approach To Quality Service

- Disney's Approach To Quality Service

- Trailering 'Rules of the Road' Updated

- 10th Annual Frank J. Flaman Foundation Gala 2016

- Why Frank Cares

Authors

Archive

Five Reasons to Upgrade Your Grain Handling

Posted by Jeff Brown Jun 20, 2023

Wish managing your bin yard was a little less complicated? A tied-in grain-handling system can make that happen. Flaman offers several innovative components that can eliminate the effort, expense, and inconvenience of getting your grain safely in your bins. Bringing them together in one place yields a bumper crop of benefits.

1. Reduce Manpower and Save on Labour Costs

Consider all the moving parts involved in traditional grain handling – augers, tractors, and semis to drive in and unload, plus the manpower to keep them moving. Setting up a grain handling system can save you the time it takes to move and operate equipment plus the expense of hiring help.

Options like belly dumping or side dumping grain into a pit that feeds a bucket elevator can be done by one person – saving you a lot of hiring, hollering, and hand signals.

2. Minimize Maintenance Costs

You’re probably all too aware of the cost of running a tractor back and forth to your grain bins. In addition to fuel, extra operating time will also mean more wear and maintenance. Your auger flighting can also wear out, suffering more metal-on-metal damage as time goes by.

A self-propelled, belt-driven bucket elevator is designed to avoid impact points, and a pit system can eliminate the need for a tractor to move or power anything.

copy.jpg)

3. Eliminate Seed and Grain Damage

Of course, if metal can damage metal, it can easily crush any seed that gets caught between an auger’s flighting and its tube. Brittle pulses like lentils and peas are particularly vulnerable to significant and costly damage.

A gentler handling option makes good economic sense. You could employ a low-cost Hutchinson Chain Loop system, operating like a sideways-mounted bucket elevator, or you could opt for the bucket elevator itself, which carries your grain in plastic buckets for minimum damage.

Walinga’s air system takes seed and grain protection even further. Its vacuum intake and blower combo gives your crop an air-cushioned ride to the bin.

4. Invest in the Future Growth of Your Operation with a Staged Expansion Approach

Not everyone can afford to set up a state-of-the-art grain handling system on day one. Fortunately, Flaman can help you structure a budget-friendly plan to expand your grain operation whenever and however you feel comfortable.

You can build up in stages over a number of years. For instance, Stage 1 might mean setting up a reliable bin-and-auger process. Your second stage might include tying all your bins together with a grated pit and bucket elevator system. In stage 3, you might add grain storage or introduce a truck scale or an overhead unload bin you can drive your truck under. Your fourth stage might see the addition of cleaning and processing equipment.

This is just an example. You could switch it up to expand your operation as you see fit. Every customer is different, and Flaman helps each one find an individual solution.

5. Increase Efficiency

Nothing saves time and money like speed and volume. Flaman offers both. Our low-maintenance grain handling equipment is proven to provide a high degree of safety for your crop and yourself. These include grain-moving options with impressive capacities of up to 20,000 bushels an hour.

From Start to Finish, We Have It Handled

If you’d like to make life on the farm more than kinda laid-back, Flaman proudly offers the best-in-class industry experts to help you do it.

You can count on our team of certified technicians. Their collective grain-handling expertise, service, and support are yours throughout the setup, optimization, and maintenance of your operation.

Get efficient this year. Talk to Flaman about the grain handling options that can start saving you money – and about the expansion you can achieve with the money you save.

Start your better bin yard conversation here.

Posted in Product Information | Tagged with grain handling walinga bucket elevator hutchinson grain pump | More articles by Jeff Brown

Move your grain with the all-new AGI Hutchinson Double Run Chain Conveyor

Posted by Paul Boechler Sep 14, 2020

The AGI Hutchinson Double Run Chain Conveyor is a brand new product to the Flaman lineup. It is built in Western Canada with the prairie farmer in mind. Manufactured at AGI’s plant in Swift Current, SK, it is designed to handle delicate crops grown on the prairies, like pulses, far more gently than an auger would.

The UHMW plastic paddles gently convey grain

Maneuverable in Tight Spaces:

Modeled after the clean grain elevator on your combine, its UHMW plastic paddles convey crops to your bin in a gentle manner. A huge benefit of this is the ability to operate at full capacity from nearly any angle, fitting into tighter spaces.

Another feature of the Double Run is the easy to use swivel arc kit, which makes the unit highly portable around the yard. You can move it from bin to bin or dryer, by simply swapping a few pins.

The swivel arc kit allows for easy maneuverability

Low Power Requirements:

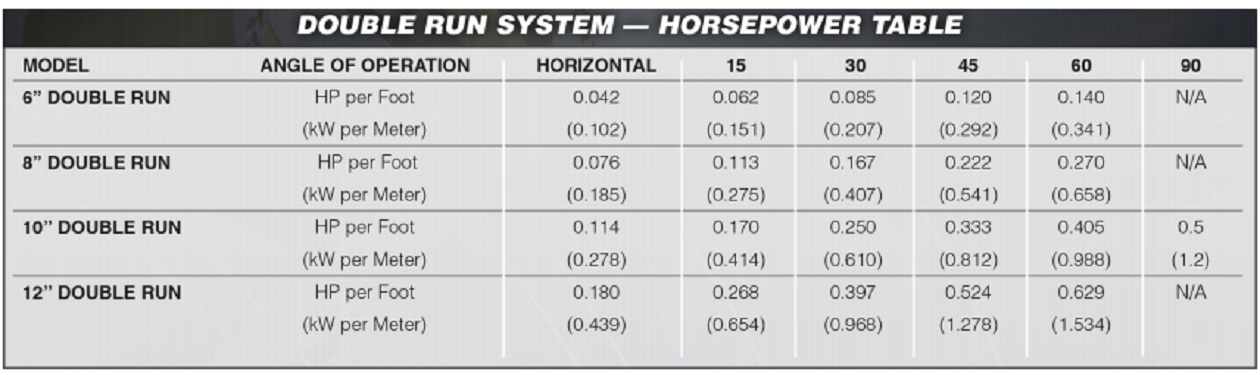

While the Double Run is powerful in getting your grain into the bin, it has a low horsepower requirement compared to alternative grain handling equipment. As an example, 8” model with a length of 82’ requires just 18 HP at a 45° angle (see chart below). These units are available with an electric motor or PTO drive, giving you plenty of power options.

Proven Reliability & Longevity:

We all know an unreliable auger can be a huge problem for your operation at harvest time. The Double Run was designed as a solution to this problem. The chain conveyor requires less maintenance and has more longevity than your typical auger. Keep the chain running straight and tensioned properly, and these units will just run. And run. And run.

Travis Frey of AGI walks us through exactly what makes this unit different:

The Double run comes in lengths of up to 82’ on the 8” and 10” models, with up to 4,000 BPH capacity on the 8” and 6,000 BPH on the 10”. It is also available in a 12” model, which has a 10,000 BPH capacity and lengths up to 130’.

Stop by your local Flaman Ag store or give us a call for more information on this unit.

Posted in New Products | Tagged with AGI Hutchinson Double Run chain conveyor grain handling grain systems Flaman | More articles by Paul Boechler

Locations

Locations