Flaman Rentals Blog

RSS feed

Categories

Recent activity

- What's it like being a Flaman Rental Dealer?

- A Brief History of the Newest Flaman Store in Swift Current

- Disney's NEW Leadership Excellence Training Course

- Disney's Approach To Quality Service

- Disney's Approach To Quality Service

- Trailering 'Rules of the Road' Updated

- 10th Annual Frank J. Flaman Foundation Gala 2016

- Why Frank Cares

Authors

Archive

Reclaim land with a Kello-Bilt Disc Ripper from Flaman

Posted by Mitch Flaman Oct 14, 2021

It’s time to get ripping this fall and reclaim that land that hasn’t been seeded in years.

When the fall weather permits, tillage and other end-of-season work is necessary to get a jump start on prepping next year’s seedbed before the spring rush. Disc ripping is a great tillage method that you can use to break up hardpan and compaction layers, manage trash and crop residue, and increase acres by reclaiming some of the low spots in your field.

In-field product demo at the Discovery Farm site in Langham, SK

Given the dry conditions this year, the opportunity to reclaim low spots and disc dried-up sloughs is available. Using a Kello-Bilt Disc Ripper from Flaman allows you to improve moisture retention and root development by digging deeper into the ground.

Kello-Bilt Disc Rippers feature five adjustable ripping shanks that allow for depths of 12”, 15”, and 18”, setting them apart from conventional tillage or other types of tillage practices. The heavy-duty shanks on this machine dig below the compaction layer beneath the soil’s surface and demolish the hardpan.

Effectively shattering the hardpan with a Kello-Bilt 275DR allows plant roots to penetrate the soil further while accessing additional nutrients and moisture.

An interesting analogy when trying to understand how disc rippers reclaim land in dried-up slough bottoms is to think of a pool liner. After years of water sitting in a low spot on your field, the water saturation in the soil tightens up and creates a layer much like a pool liner. Disc ripping a dried-up slough bottom penetrates this liner, aerating the soil and allowing it to breathe again.

This increases soil efficiency with better moisture retention, microbial activity, and balanced pH levels to help reduce saline patches. In other words, “healthier soil” that will produce healthier plants.

The beauty of seeding into a low spot (once the slough bed has been properly disc ripped) is the likelihood of that land seeing moisture in the following crop year. In dry growing seasons, this additional moisture can be the difference between a heavy, high-busheling crop and a below-average yield.

For more information on how a Kello-Bilt Disc Ripper can help with seedbed preparation, managing post-harvest crop residue and trash this fall, or increasing acres next year by reclaiming land that hasn’t been seeded in years, talk to one of our ag specialists at your nearest Flaman location.

Shaun walks through the features of the Kello-Bilt 275 Disc Ripper

-----

Interested in trying out the Kello-Bilt 275DR on your farm but not ready to purchase? We offer short-term rentals of tillage and field prep equipment, as well as grain handling equipment, hay and livestock equipment, trailers, and more. Contact your local dealer for rental inquiries and current product availability.

Posted in New Products | Tagged with Kello-Bilt disc disc ripper disc ripping tillage | More articles by Mitch Flaman

Heavy harrow meets high speed tillage: Why the Schulte SoilStar Disc Harrow is the best of both worlds

Posted by Mitch Flaman Jun 03, 2021

There are a lot of different discs and harrows on the market, but there is nothing quite like the Schulte SoilStar Disc Harrow.

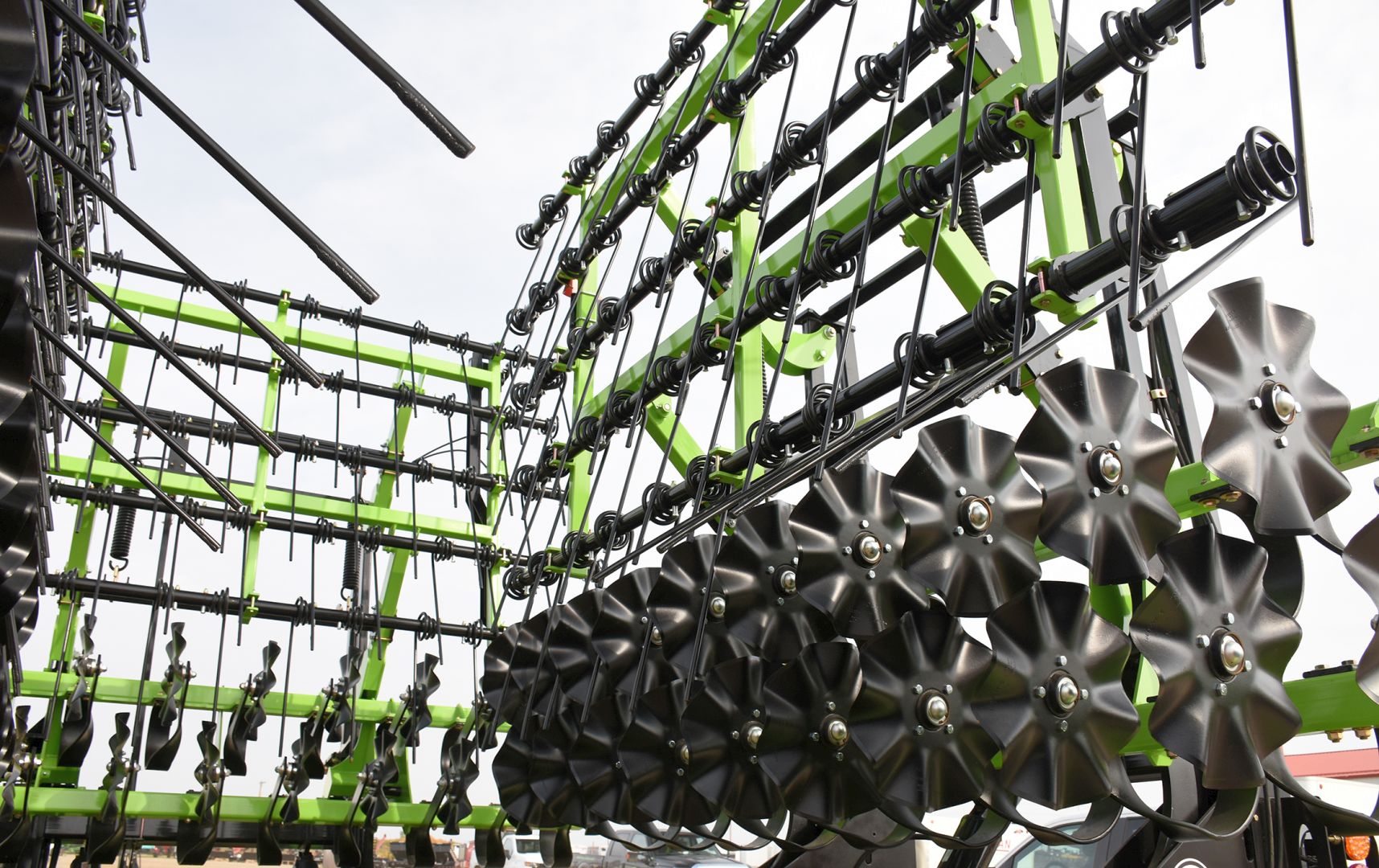

Whether you are cleaning up after a bumper crop or dealing with pulse residue post-harvest, properly managing the trash in your field is important prior to seeding. The Schulte DHX combines a 5-bar heavy harrow and a double row of wavy coulter discs. This unique design is engineered to properly size straw and manage it in the top 1.5” – 2” of the soil.

Pictured above: 5-bar heavy harrow & wavy coulter discs

Although traditional discs can be effective at leveling a field, they are also known to bury heavy straw residue down into the soil and not properly size it. The result of this is that the field may look like it has been left clean, but the straw remains intact below the surface. The problems arise when the air seeder brings the straw back to the surface in spring and creates trash piles.

Harrowing can also prove effective in providing a finer finish to the field prior to seeding, but heavy trash that remains after a large-yielding crop can bunch up and create substantial piles of material behind the equipment.

Schulte 60' Disc Harrow in action

The Schulte Disc Harrow is the best of both worlds. The 18” double row of wavy coulter discs are spaced at 7.2” and are available in 8 wave and 13 wave options – effectively sizing the straw in the top 1.5” – 2” of the soil. This levels the soil without being overly aggressive and without over-disturbing the topsoil like a concave disc.

The coulter discs move independently from the main frame, which allows the operator to either maximize the weight of the machine on the cutting edge of the discs or lift them completely and use the DHX as a 5-bar harrow.

The Schulte SoilStar is available in 36’ and 60’ widths and requires a minimum of 8 HP per foot. Depending on the stubble and soil conditions, the DHX can be pulled between 7-10 mph.

DHX-600 (60' model)

DHX-360 (36' model)

DHX-360 (36' model)

Whether you are prepping the field in late fall or early spring, the Schulte DHX is proven to get you in the field sooner and maximize your time. With the ability to adjust the disc depth and tine angle from 35 degrees to 90 degrees, you no longer have to wait for ideal conditions to get rolling – the Schulte Disc Harrow is just as effective in wet conditions. When used in the springtime, the DHX can warm up the soil and speed up weed seed germination to promote a proper pre-seed burn off for producers hitting the field with a sprayer.

The versatility of the Schulte Disc Harrow is what sets it apart from the competition in the tillage world.

Reagan from Schulte Industries walks us through the features of the DHX-360

-----

For more information on how the Schulte DHX can help you manage post-harvest trash and straw residue in your field this fall or quicken soil warming and increase water penetration next spring, talk to one of our ag specialists at your nearest Flaman location.

Posted in Product Information | Tagged with Schulte DHX disc harrow soilstar 5-bar coulter discs | More articles by Mitch Flaman

After 50 years, Kello-Bilt discs remain innovative, family-manufactured, and built to stand up

Posted by Mitch Flaman Feb 03, 2021

When buying a field disc, you need the confidence to know that it is going to work the way you expect when you need it and not break down, leaving you stranded with work to be done. This is why Flaman chose to team up with Kello-Bilt products over 40 years ago. Like Flaman, Kello-Bilt remains a family-owned business that keeps quality and reputation top of mind. A field disc is meant to be put through tough conditions. Continued innovation is what has kept Kello-Bilt tillage equipment ahead of the curve and outlasting its competitors.

Kello-Bilt Tandem Disc - Model 225TSW

For over 50 years, Kello-Bilt discs have been Canadian-made to “be better”. They’re built heavy and designed to last in the toughest conditions. The company has continued to evolve with experience and improve the things that “didn’t work” or simply didn’t stand up to other discs in the tough Canadian environment. This is how the idea for the self-lubricating oil-bath bearing was born. The self-lubricating oil-bath bearing proved to be superior to traditional greaseable ball bearings.

Today, regardless of price, Kello-Bilt discs are still manufactured to the highest standard with Canadian and North American steel. They are constructed with high-strength steel tubing, heavy gussets, and powder-coated components to ensure best-in-class quality and performance. This ensures the longevity of your purchase for years to come. The oil-bath bearings and boron steel blades are designed and sourced from Brazil and Argentina specifically for Kello-Bilt. Boron steel blades are less brittle than traditional carbon steel blades.

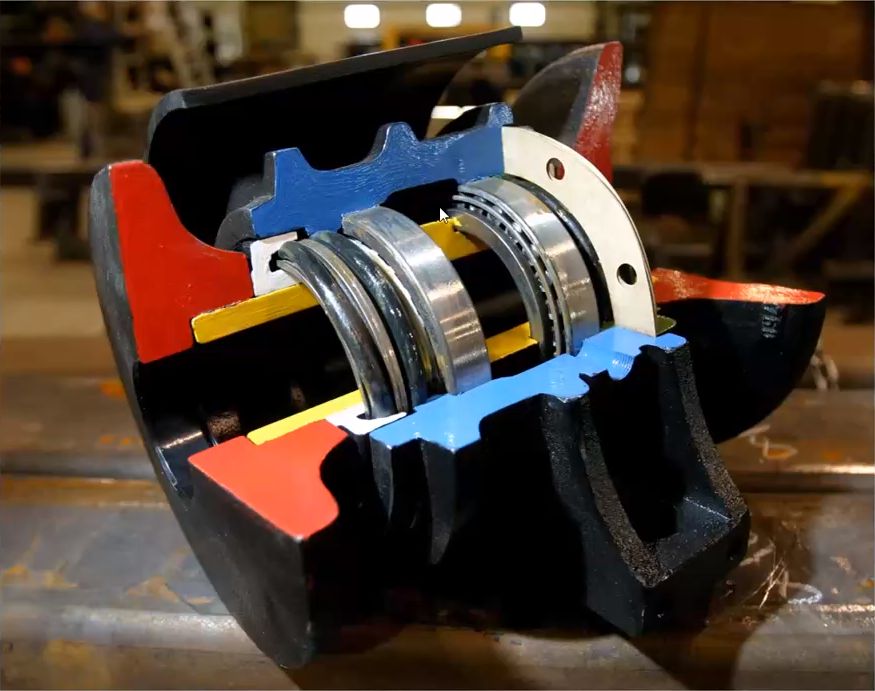

Oil-Bath Bearing Interior

Oil-Bath Bearing InteriorThe oil-bath bearing uses two tapered roller bearings mounted in a cast housing. The dual-cone seal constantly lubricates the bearing. They sit on the interior axle, which is never in contact with the actual gang shaft. Tapered roller bearings are ideal for a disc application because they are designed for side thrust. Most of the pressure a disc blade faces is side pressure, NOT radial pressure. Ball bearings are designed for radial pressure. Oil-bath bearings are extremely low maintenance. Testimonials show Kello-Bilt discs from the 1980s are still operating with their original bearings after over five or more sets of replacement blades. The beauty of the oil-bath bearing is that they’re rebuildable. As long as you make sure not to run the blades too loose, as it will put pressure on the housing and cause leakage, the bearings can last for decades.

Kello-Bilt Offset Disc - Model 275

If you’re serious about purchasing a quality field disc, contact your local Flaman dealer today. A Kello-Bilt disc with oil-bath bearings might be as serious as you are.

Posted in New Products | Tagged with Kello-Bilt disc field disc tillage | More articles by Mitch Flaman

Locations

Locations