Flaman Rentals Blog

RSS feed

Categories

Recent activity

- What's it like being a Flaman Rental Dealer?

- A Brief History of the Newest Flaman Store in Swift Current

- Disney's NEW Leadership Excellence Training Course

- Disney's Approach To Quality Service

- Disney's Approach To Quality Service

- Trailering 'Rules of the Road' Updated

- 10th Annual Frank J. Flaman Foundation Gala 2016

- Why Frank Cares

Authors

Archive

Tips and Resources for a Safe Harvest

Posted by Jennifer Thompson Aug 17, 2020

As harvest begins to start in many parts of Western Canada, Flaman is here to provide the tools and equipment you need to get your crop off quickly and safely. Along with our wide variety of Harvest Helpers to aid you in your work, we’ve collected some important and useful safety tips for harvest time. We want to make sure all our customers return safely from the field and have the resources to support their employees and family members on the farm.

This post will look at 4 main types of safety:

- Grain bin entrapment

- Fire safety and prevention

- Machinery and power lines

- COVID-19 safety

Grain Bin Entrapment

Tough grain is one of the leading causes for producers to enter a bin. Many studies have shown that entering a bin to break up spoiled grain while operating unloading equipment is the leading cause of grain entrapment. A person could become completely covered within 20 seconds. Across Canada, there’s an average of six fatalities every year from grain entrapment or engulfment.

If you need to enter a bin to asses grain, there is a Grain Bin Assessment chart from the Canadian Agricultural Safety Association you can use to assess if it’s safe to enter the bin.

This fact sheet from the Canadian Centre for Health and Safety in Agriculture also has some helpful information about how grain entrapment occurs, as well as preventative and safety measures.

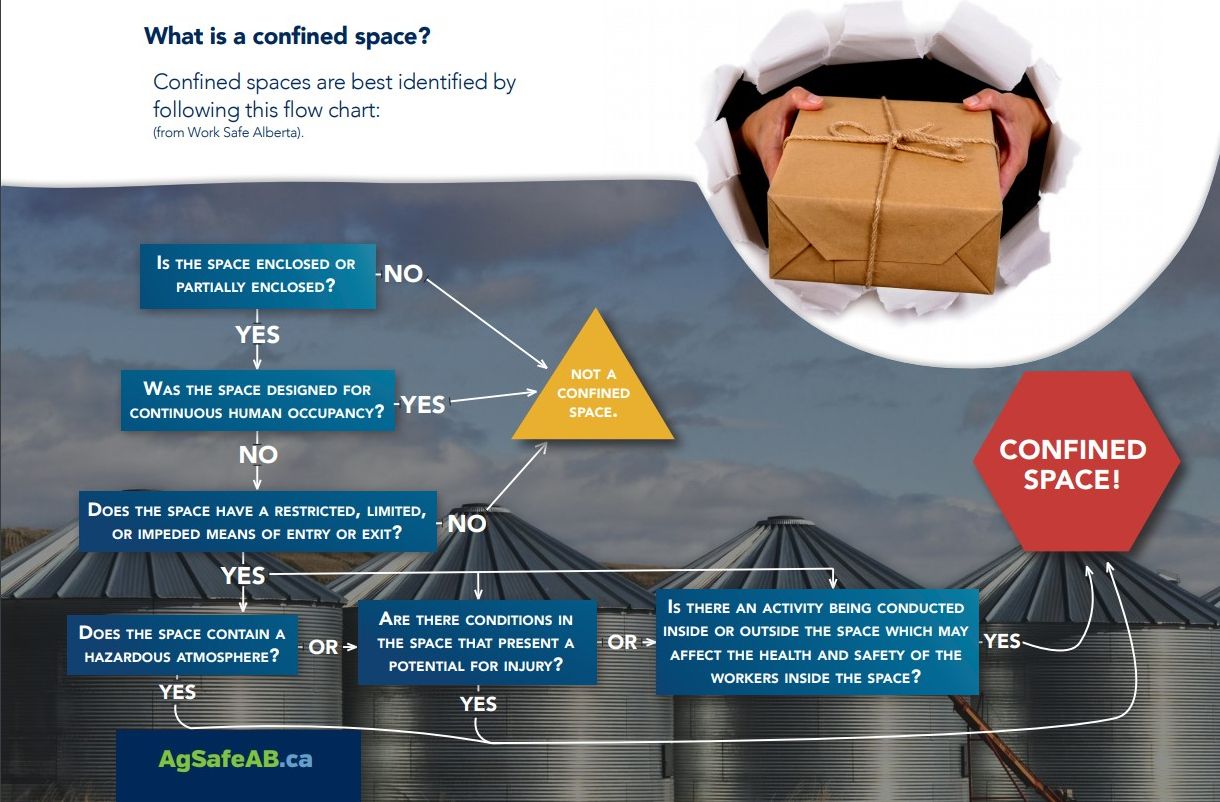

And finally, if you wish to create a Confined Space Management Program for your farm, this quick start guide from Ag Safe Alberta is a useful tool. Along with grain bins, confined spaces also include sumps, wells, feed bins, attics and even some equipment.

Fire Safety and Prevention

Fires in the field can happen all too suddenly when working with dry, flammable material and hot mufflers and electrical wiring. There are some simple pre-cautionary measures you can take to help avoid the risk of injury or loss of equipment due to fire.

- Have working fire extinguishers mounted on equipment, ideally one in the cab and one accessible from the ground. Alberta Agriculture recommends a 10 pound dry chemical, multi-purpose ABC extinguisher and a 2.5 gallon pressurized water extinguisher on combines.

- Remove crop residue, dust, debris, dirt and excess lubricant around all heat sources regularly. Check for a buildup of combustible crop residue around engines and exhaust systems, concealed drive belts and pulleys that can overheat due to friction.

- Be careful when using low clearance vehicles in fields, as exhaust pipes and catalytic converters can ignite dry grass or stubble.

- Check exposed wiring and fuel/hydraulic lines for damage, wear and deterioration.

- Allow engines to cool before refueling.

And for added safety, Flaman carries a variety of firefighting pump and tank units, such as the Enduraplas Fire Ranger or the BE Fire Cart, to allow you to quickly put out any fires in the field while harvesting.

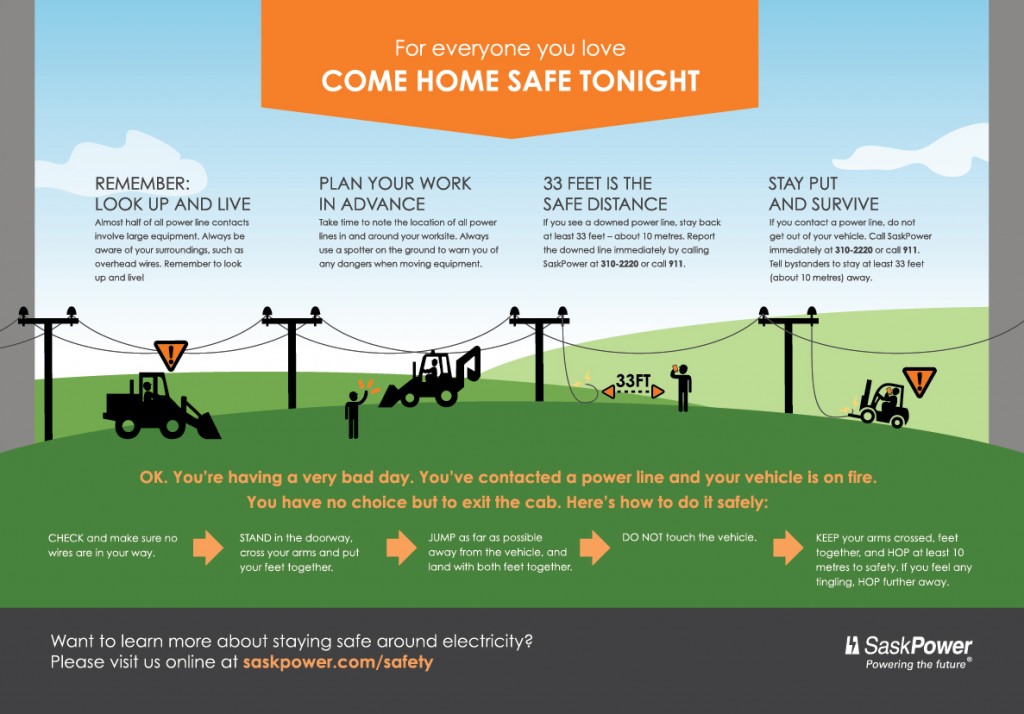

Machinery and Power Lines

Electrical safety is another important area to be aware of when working with large machinery on a farm. More than 40% of agricultural workers in Canada have reported direct hits or near misses with power lines. In 2019, there were 326 farm safety incidents reported to Sask Power. The most common causes of electrocutions on the farm are portable grain augers, large combines, high clearance sprayers and other tall equipment that can come into contact with overhead power lines.

There are two types of electrical injury that can occur:

- Electric shock, when electric current passes through the body causing injury or death.

- Arc flashes: a blast of energy caused by an electric arc, which can produce sounds waves, extreme heat, shrapnel and more, This can lead to lung injuries, ruptured ear drums, burns, blindness or death.

This guide “Electrical Safety on Saskatchewan Farms" from Sask Power talks about potential risks and hazards and offers safety tips, guides and checklists to make sure you and your workers come home safe. Or you can print out this Farm Safety Checklist to make sure everyone knows how to avoid overhead lines and what to do if an accident occurs.

COVID-19 Safety

This year, farming operations will have the added tasks of protecting workers and their family from COVID-19. As an essential service, we recognize that farmers must continue to work to grow our food and feed our country.

Along with the general pre-cautions such as hand washing, physical distancing, cleaning of work attire and wearing gloves, this fact sheet from the Canadian Centre for Occupation Health and Safety offers many safety tips specifically for the agricultural industry in areas such as:

- Transportation

- Sanitation

- Group Living and Residence Recommendations

- Team and Site Management

- And much more.

For those interested in creating an overall safety plan for their operation, this workbook from Ag Safe Alberta lays out the steps to create your own Farm Safe Plan.

Posted in Ag news | Tagged with harvest safety farming grain bins electrical safety | More articles by Jennifer Thompson

NECO Grain Dryer Build

Posted by Paul Boechler Jun 12, 2019

We recently had the opportunity to build the largest private NECO grain dryer in Western Canada – a NECO Mixed Flow 6 Burner D24380 -- for a large farming operation outside of Edmonton, AB. It was a complex endeavour with many moving parts, and it required many hours of planning to execute..jpg)

We had help from several outside sources: Freeway Transport, who were responsible for the dryer delivery; Xcaliber Crane & Rigging who handled the hoisting of the dryer; and Continental Bins, who provided assembly services. Additionally, Ron Kleuskens from NECO supervised the build and many members of the Flaman Nisku team assisted throughout the day where they were needed. And most importantly, the 4 owners of the farm and their sons, daughters, grandchildren & significant others were all present at one time or another throughout the day. They were the real supervisors!

.jpg)

Build Day was kicked off with the delivery of the dryer. This consisted of 7 truckloads originating in Omaha, Nebraska. Each delivery was staggered by 2 hours, which allowed enough time for our crane and assembly teams to position and install each section before the next was delivered.

.jpg)

With the help of our partners and employees – more than 20 people in total -- we were able to install this behemoth of a dryer in one jampacked, 10 hour day.

.jpg)

The dryer will serve as a flagship operation in the area and will likely create business not only for our customer’s farm, but others in the area as well. It’ll be an economic driver in the area for many years to come. We're thankful to be a part of this project and meet the needs of our customer. Customer service is one of the core beliefs Flaman was founded on and it’s why we’re celebrating 60 years in the agriculture industry in Western Canada.

Posted in Ag news | Tagged with grain dryer farming neco flaman install | More articles by Paul Boechler

Locations

Locations