Flaman Rentals Blog

RSS feed

Categories

Recent activity

- What's it like being a Flaman Rental Dealer?

- A Brief History of the Newest Flaman Store in Swift Current

- Disney's NEW Leadership Excellence Training Course

- Disney's Approach To Quality Service

- Disney's Approach To Quality Service

- Trailering 'Rules of the Road' Updated

- 10th Annual Frank J. Flaman Foundation Gala 2016

- Why Frank Cares

Authors

Archive

Reduce labour when filling bins: Automate your grain handling site with a Walinga Blower System

Posted by Calla Simpson Aug 31, 2020

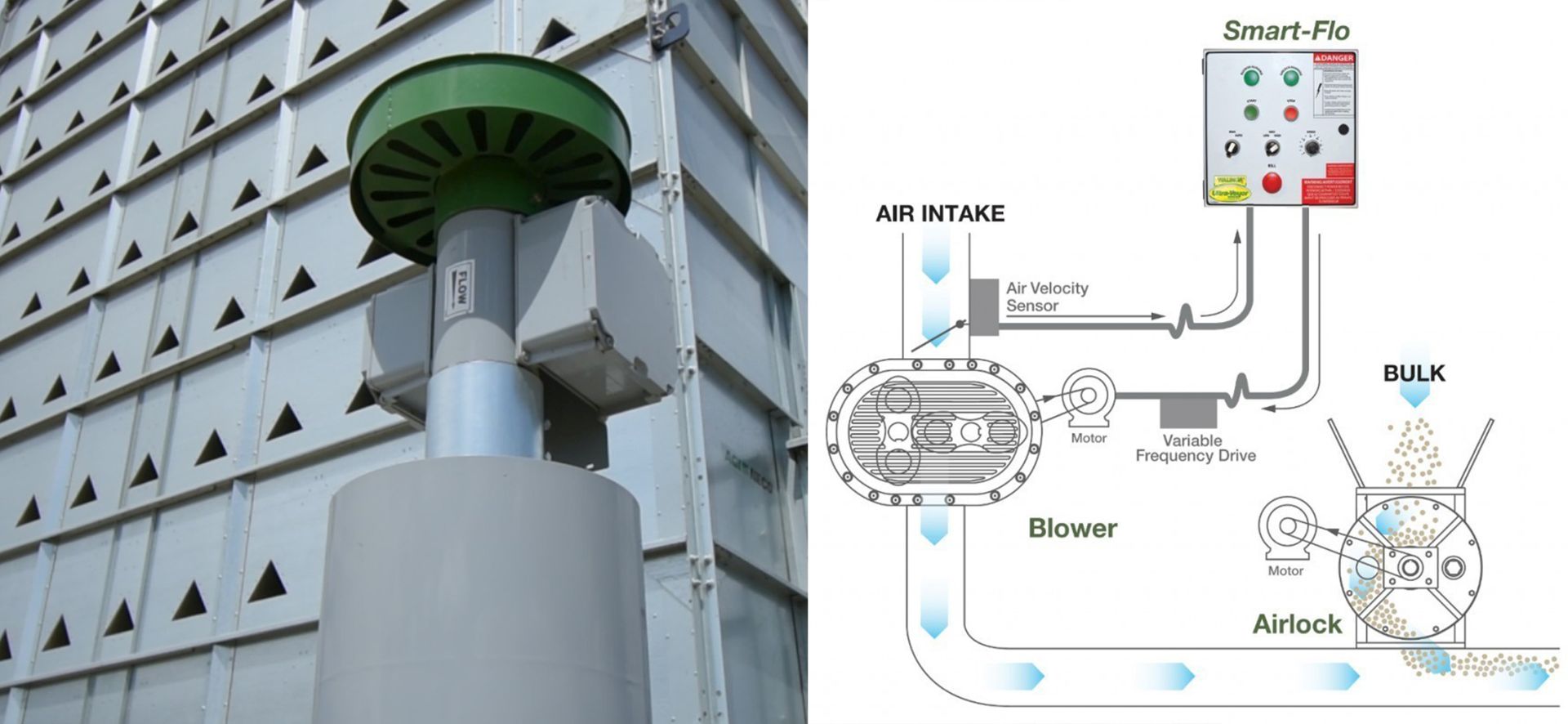

A Walinga Pneumatic Blower System may be one of the most versatile pieces of equipment you can add to your Grain Handling lineup. The Ultra-Veyor is designed to fill bins of various heights and distances from the ground up, allowing you to easily add the system to any pre-existing site.

Walinga Sales Rep Doug Termeer explains how a blower system works

Many yard sites weren’t originally designed with the thought of adding a grain handling system or grain dryer down the line. As farms continue to grow, larger bins are being installed and grain storage is being built further and further away. The only way to hit all these bins of different sizes and distances economically is with a blower system. By allowing you to keep the current bins and other infrastructure you have already invested in, a Walinga Ultra-Veyor prevents you from having to redesign your entire yard site – saving you a lot of money in the long run.

A grain handling setup in Saskatchewan utilizing a Walinga blower system to reach bins of various heights

A grain handling setup in Saskatchewan utilizing a Walinga blower system to reach bins of various heights

Walinga blower systems are also very flexible and expandable, so you don’t need to have your whole yard designed and planned out ahead of time. You can easily expand down the road as your business grows and you start to add more acres or dry more grain. These systems can be installed under driveways to reduce the risk of damaging any pipes as you load/unload trucks in your yard.

The Walinga Ultra-Veyor is also a great add-on to any grain dryer, especially continuous flow dryers like NECO. Automating your grain dryer and grain handling reduces the number of augers, legs, and additional trucking necessary to move grain around your yard. This maximizes accessibility to any drying or storage facility. Your grain can go straight from the dryer into the final storage bin, so you don’t have to move it around multiple times before you get it where you want it in the end. It’s faster, more efficient, and most importantly, safer.

A NECO Grain Dryer unloading into a Walinga system

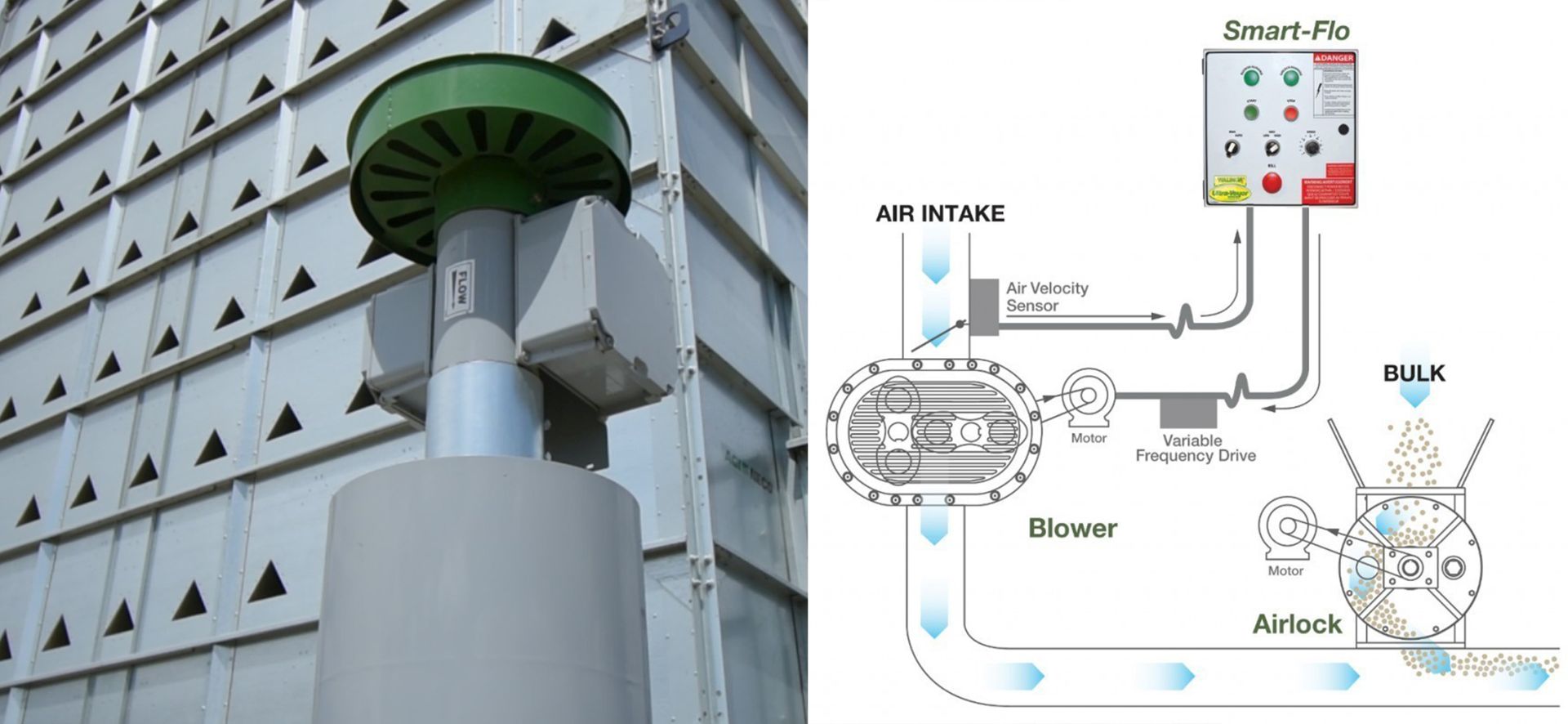

With the Smart-Flo feature on your Walinga blower, you have the ability to control the airspeed which reduces unnecessary damage to product and piping. This Variable Frequency Drive (VFD) system monitors and adjusts motor speeds depending on crop type, volume of product, and distance – optimizing performance and reducing energy costs. The Smart-Flo system can also be wired into your continuous flow grain dryer to speed up and slow down as necessary.

A blower system is not only an economic and affordable solution for long-distance conveying, it is also simple to install and is gentle on product – moving grain virtually dust and damage-free. Walinga Ultra-Veyors can move anywhere from 400 bushels/hour to 2,100 bushels/ hour, depending on the size of your operation.

Hear first-hand how a Walinga Ultra-Veyor made a positive impact on this customer's operation

Want to invest in a Walinga Pneumatic Blower system and automate your grain handling site this year? Contact us to schedule a free, no-commitment site assessment today.

-----

For more information on our grain handling and grain drying solutions, talk to one of our agriculture specialists at your nearest Flaman location.

Posted in Product Information | Tagged with grain systems grain handling Walinga Ultra-Veyor blower system NECO grain dryer | More articles by Calla Simpson

Reduce labour when filling bins: Automate your grain handling site with a Walinga Blower System

Posted by Calla Simpson Aug 31, 2020

A Walinga Pneumatic Blower System may be one of the most versatile pieces of equipment you can add to your Grain Handling lineup. The Ultra-Veyor is designed to fill bins of various heights and distances from the ground up, allowing you to easily add the system to any pre-existing site.

Walinga Sales Rep Doug Termeer explains how a blower system works

Many yard sites weren’t originally designed with the thought of adding a grain handling system or grain dryer down the line. As farms continue to grow, larger bins are being installed and grain storage is being built further and further away. The only way to hit all these bins of different sizes and distances economically is with a blower system. By allowing you to keep the current bins and other infrastructure you have already invested in, a Walinga Ultra-Veyor prevents you from having to redesign your entire yard site – saving you a lot of money in the long run.

A grain handling setup in Saskatchewan utilizing a Walinga blower system to reach bins of various heights

A grain handling setup in Saskatchewan utilizing a Walinga blower system to reach bins of various heights

Walinga blower systems are also very flexible and expandable, so you don’t need to have your whole yard designed and planned out ahead of time. You can easily expand down the road as your business grows and you start to add more acres or dry more grain. These systems can be installed under driveways to reduce the risk of damaging any pipes as you load/unload trucks in your yard.

The Walinga Ultra-Veyor is also a great add-on to any grain dryer, especially continuous flow dryers like NECO. Automating your grain dryer and grain handling reduces the number of augers, legs, and additional trucking necessary to move grain around your yard. This maximizes accessibility to any drying or storage facility. Your grain can go straight from the dryer into the final storage bin, so you don’t have to move it around multiple times before you get it where you want it in the end. It’s faster, more efficient, and most importantly, safer.

A NECO Grain Dryer unloading into a Walinga system

With the Smart-Flo feature on your Walinga blower, you have the ability to control the airspeed which reduces unnecessary damage to product and piping. This Variable Frequency Drive (VFD) system monitors and adjusts motor speeds depending on crop type, volume of product, and distance – optimizing performance and reducing energy costs. The Smart-Flo system can also be wired into your continuous flow grain dryer to speed up and slow down as necessary.

A blower system is not only an economic and affordable solution for long-distance conveying, it is also simple to install and is gentle on product – moving grain virtually dust and damage-free. Walinga Ultra-Veyors can move anywhere from 400 bushels/hour to 2,100 bushels/ hour, depending on the size of your operation.

Hear first-hand how a Walinga Ultra-Veyor made a positive impact on this customer's operation

Want to invest in a Walinga Pneumatic Blower system and automate your grain handling site this year? Contact us to schedule a free, no-commitment site assessment today.

-----

For more information on our grain handling and grain drying solutions, talk to one of our agriculture specialists at your nearest Flaman location.

Posted in Product Information | Tagged with grain systems grain handling Walinga Ultra-Veyor blower system NECO grain dryer | More articles by Calla Simpson

Early season utilization: Increase the grade of your grain with a NECO Grain Dryer

Posted by Calla Simpson Aug 26, 2020

As harvest is well underway in most areas of the province, many producers are utilizing their grain dryers early on this season and increasing the available window to combine. Some farmers have even noticed increases in their durum quality as their grade improves after drying.

20% moisture durum before going into the NECO grain dryer (left) and 14.5% moisture durum after being dried (right)

20% moisture durum before going into the NECO grain dryer (left) and 14.5% moisture durum after being dried (right)

Nolan Gettis, a farmer in central Saskatchewan, discusses how his NECO Grain Dryer has improved his operation:

“Two years ago, I would have been waiting to combine saying, ‘It’s getting close’. Right now, I’m full on harvesting because I have this dryer as a tool. I’m not waiting to use it. I’m literally taking off 20% durum and it’s coming out dry and just shining. It’s amazing how much better this durum looks once it comes out of that dryer. When you have a crop of unicorn #1 amber durum, you’ve gotta go get it.

I’d have to say the biggest benefit of this NECO dryer is that we’ve taken on more acres this year and I’ve already conquered that land without buying another combine. I have three bins on the go; a dry bin, an aeration bin, and the dryer. It’s a total harvest management tool.”

Nolan's grain drying setup in Semans, SK

Mixed flow dryers reduce the risk of crop damage, resulting in higher test weights. This drying process helps mature the kernels and brings out the rich colour evenly, producing higher quality grain with more consistent results. This dramatic difference in quality increases profitability and improves yield.

It's not too late – contact us to book your dryer install with Flaman today.

-----

For more information on our grain handling and grain drying solutions, talk to one of our agriculture specialists at your nearest Flaman location.

Posted in Product Information | Tagged with grain systems grain handling grain drying NECO grain dryer mixed flow continuous flow | More articles by Calla Simpson

Early season utilization: Increase the grade of your grain with a NECO Grain Dryer

Posted by Calla Simpson Aug 26, 2020

As harvest is well underway in most areas of the province, many producers are utilizing their grain dryers early on this season and increasing the available window to combine. Some farmers have even noticed increases in their durum quality as their grade improves after drying.

20% moisture durum before going into the NECO grain dryer (left) and 14.5% moisture durum after being dried (right)

20% moisture durum before going into the NECO grain dryer (left) and 14.5% moisture durum after being dried (right)

Nolan Gettis, a farmer in central Saskatchewan, discusses how his NECO Grain Dryer has improved his operation:

“Two years ago, I would have been waiting to combine saying, ‘It’s getting close’. Right now, I’m full on harvesting because I have this dryer as a tool. I’m not waiting to use it. I’m literally taking off 20% durum and it’s coming out dry and just shining. It’s amazing how much better this durum looks once it comes out of that dryer. When you have a crop of unicorn #1 amber durum, you’ve gotta go get it.

I’d have to say the biggest benefit of this NECO dryer is that we’ve taken on more acres this year and I’ve already conquered that land without buying another combine. I have three bins on the go; a dry bin, an aeration bin, and the dryer. It’s a total harvest management tool.”

Nolan's grain drying setup in Semans, SK

Mixed flow dryers reduce the risk of crop damage, resulting in higher test weights. This drying process helps mature the kernels and brings out the rich colour evenly, producing higher quality grain with more consistent results. This dramatic difference in quality increases profitability and improves yield.

It's not too late – contact us to book your dryer install with Flaman today.

-----

For more information on our grain handling and grain drying solutions, talk to one of our agriculture specialists at your nearest Flaman location.

Posted in Product Information | Tagged with grain systems grain handling grain drying NECO grain dryer mixed flow continuous flow | More articles by Calla Simpson

Dry your grain with ease: Get ahead of harvest this year and book your NECO dryer install with Flaman today

Posted by Calla Simpson Jun 26, 2020

There are many advantages to owning a grain dryer. As we learned last year in Western Canada, harvest 2019 had its challenges; most of which showed up when the crop needed to come off the field. Being able to dry your grain allows you to better manage your timeline and start combining as soon as it’s time to go! The earlier you can get started, the less likely you are to get caught with crop out in the field over winter.

NECO Mixed Flow Grain Dryers are designed to easily and efficiently condition all types of grain for storage. With no screens to clean or unplug, this industry-leading grain dryer is designed not only for its performance, but also its versatility.

The flexible, modular design of these grain dryers make for easy installation and can be customized and expanded to suit any farming operation.

A time lapse of a NECO Grain Dryer installation near Saskatoon

The NECO Grain Dryer’s mixed flow operation ensures even heating and cooling to provide consistent, high-quality grain. The improved air flow, quieter fans, and unequalled fuel efficiency make this dryer a valuable addition to any farming operation.

NECO dryers use Commander Control with a Dryer Master moisture control system to protect the quality of your grain and prevent over- or under-drying. The COMMANDnet system allows remote access to your NECO Grain Dryer to monitor its performance from your smartphone or computer – providing you with total control over your dryer wherever you may be.

It is never too early to start planning for harvest, as we never know what mother nature has in store for us. Bookings are filling up fast, but there are still a few spots left to get your name on a dryer for fall. Our Grain Systems team can customize a complete grain drying system to suit your needs, guiding the setup and installation, and providing service and maintenance along the way.

Hear first-hand from Flaman customers what a NECO dryer can do for your operation

Be ready to get ahead of harvest this year – contact us to book your dryer install with Flaman today.

-----

For more information on our grain handling and grain drying solutions, talk to one of our agriculture specialists at your nearest Flaman location.

Posted in Product Information | Tagged with grain systems grain handling grain drying NECO grain dryer | More articles by Calla Simpson

Dry your grain with ease: Get ahead of harvest this year and book your NECO dryer install with Flaman today

Posted by Calla Simpson Jun 26, 2020

There are many advantages to owning a grain dryer. Being able to dry your grain allows you to better manage your timeline and start combining as soon as it’s time to go! The earlier you can get started, the less likely you are to get caught with crop out in the field over winter.

NECO Mixed Flow Grain Dryers are designed to easily and efficiently condition all types of grain for storage. With no screens to clean or unplug, this industry-leading grain dryer is designed not only for its performance, but also its versatility.

The flexible, modular design of these grain dryers make for easy installation and can be customized and expanded to suit any farming operation.

A time lapse of a NECO Grain Dryer installation near Saskatoon

The NECO Grain Dryer’s mixed flow operation ensures even heating and cooling to provide consistent, high-quality grain. The improved air flow, quieter fans, and unequalled fuel efficiency make this dryer a valuable addition to any farming operation.

NECO dryers use Commander Control with a Dryer Master moisture control system to protect the quality of your grain and prevent over- or under-drying. The COMMANDnet system allows remote access to your NECO Grain Dryer to monitor its performance from your smartphone or computer – providing you with total control over your dryer wherever you may be.

It is never too early to start planning for harvest, as we never know what mother nature has in store for us. Bookings are filling up fast, but there are still a few spots left to get your name on a dryer for fall. Our Grain Systems team can customize a complete grain drying system to suit your needs, guiding the setup and installation, and providing service and maintenance along the way.

Hear first-hand from Flaman customers what a NECO dryer can do for your operation

Be ready to get ahead of harvest this year – contact us to book your dryer install with Flaman today.

-----

For more information on our grain handling and grain drying solutions, talk to one of our agriculture specialists at your nearest Flaman location.

Posted in Product Information | Tagged with grain systems grain handling grain drying NECO grain dryer | More articles by Calla Simpson

NECO Grain Dryer Build

Posted by Paul Boechler Jun 12, 2019

We recently had the opportunity to build the largest private NECO grain dryer in Western Canada – a NECO Mixed Flow 6 Burner D24380 -- for a large farming operation outside of Edmonton, AB. It was a complex endeavour with many moving parts, and it required many hours of planning to execute..jpg)

We had help from several outside sources: Freeway Transport, who were responsible for the dryer delivery; Xcaliber Crane & Rigging who handled the hoisting of the dryer; and Continental Bins, who provided assembly services. Additionally, Ron Kleuskens from NECO supervised the build and many members of the Flaman Nisku team assisted throughout the day where they were needed. And most importantly, the 4 owners of the farm and their sons, daughters, grandchildren & significant others were all present at one time or another throughout the day. They were the real supervisors!

.jpg)

Build Day was kicked off with the delivery of the dryer. This consisted of 7 truckloads originating in Omaha, Nebraska. Each delivery was staggered by 2 hours, which allowed enough time for our crane and assembly teams to position and install each section before the next was delivered.

.jpg)

With the help of our partners and employees – more than 20 people in total -- we were able to install this behemoth of a dryer in one jampacked, 10 hour day.

.jpg)

The dryer will serve as a flagship operation in the area and will likely create business not only for our customer’s farm, but others in the area as well. It’ll be an economic driver in the area for many years to come. We're thankful to be a part of this project and meet the needs of our customer. Customer service is one of the core beliefs Flaman was founded on and it’s why we’re celebrating 60 years in the agriculture industry in Western Canada.

Posted in Ag news | Tagged with grain dryer farming neco flaman install | More articles by Paul Boechler

Locations

Locations