Flaman Rentals Blog

RSS feed

Categories

Recent activity

- What's it like being a Flaman Rental Dealer?

- A Brief History of the Newest Flaman Store in Swift Current

- Disney's NEW Leadership Excellence Training Course

- Disney's Approach To Quality Service

- Disney's Approach To Quality Service

- Trailering 'Rules of the Road' Updated

- 10th Annual Frank J. Flaman Foundation Gala 2016

- Why Frank Cares

Authors

Archive

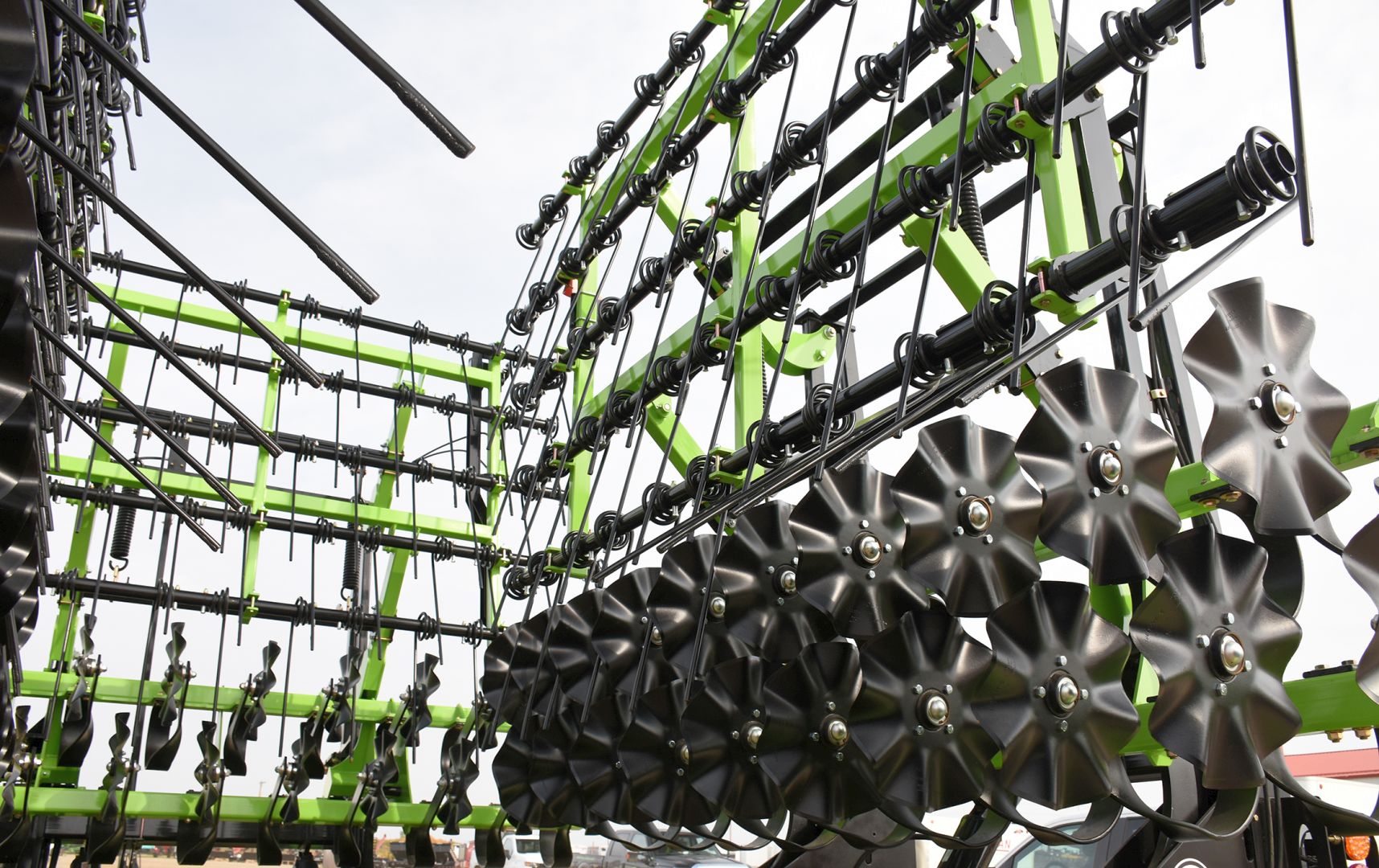

6 Reasons to Use a Riteway 7-Bar Harrow This Year

Posted by Mitch Flaman May 06, 2022

When it’s time to get your fields prepped for seeding, there are a few different equipment options to choose from.

For many years, harrows have been used to prepare fields in different capacities. Whether you are levelling off ruts, busting up hardpan, or removing trash before seeding, both the Riteway 5-bar and 7-bar harrows have a specific purpose in the tillage cycle. With low-till or zero-tillage farming practices gaining popularity in the last decade, you need a way to create ideal seedbeds for your crop.

Riteway 5-Bar Heavy Harrow in use

Heavy harrows, often known as 5-bar harrows, are very common and do a great job moving dirt, even in wet conditions. The Riteway 7-bar harrow is lighter than a traditional heavy harrow and has twice as many tines, offering you the flexibility you need to deal with excess straw post-harvest and residue management before seeding.

.jpg)

Riteway 7-Bar Harrow

We put together six reasons why you should consider using a Riteway 7-bar harrow this year.

1. Trash and Residue Removal

“At its most basic point: if you’re looking to move soil – stick with your 5-bar, but if you’re looking for trash management there’s no better way to go than the 7-bar harrow.”

Brad Grass, Territory Sales Manager at Riteway Manufacturing

Think about how you use a large fan rake to clean up all the leaves in the fall. You go over the surface of your lawn, gently collecting the leaves and removing them. When using a garden rake, you collect everything from the roots of your grass – eliminating everything that protects the soil.

7-bar harrows work much the same as a large leaf rake, cleaning up and breaking down straw residue, while leaving the soil mildly agitated. Featuring twice as many tines as a heavy harrow, the 7-bar’s ½” tines provide better agitation as the harrow floats over the field – allowing for greater trash removal and distribution.

.jpg) 24" long 1/2" tines on the Riteway 7-Bar Harrow

24" long 1/2" tines on the Riteway 7-Bar Harrow

2. Moisture Retention

The smaller diameter tines on the 7-bar harrow provide greater agitation while disturbing less ground. By only mixing up the top layer of the soil, it allows the moisture to stay in the ground. The goal is to remove extra trash on the surface, not dry out the soil.

3. Less Soil Compaction

The 82’ Riteway 7-bar harrow weighs 19,900 lbs and is the heaviest and strongest 7-bar in its class. Despite its weight, the 7-bar won’t compact the soil down as much as a heavy harrow because it floats over the topsoil instead of digging down. Less compaction, combined with better moisture retention, creates a better environment for plant development.

Riteway 7-Bar Harrow in use

4. Seed Bed Prep

Remove all the trash and debris left from harvest and prepare your seedbeds without removing soil. This allows the seed drills to move easily through the field with less straw build-up around the knife. After using a 7-bar harrow, you’ll end up with a nice, clean surface for a fresh start in the spring.

Riteway 7-Bar Harrow field demo

5. Herbicide Application

As some weeds become resistant to certain herbicides, older chemicals are making a comeback. Because granular herbicide mixes well with topsoil, the 7-bar harrow can effectively protect your crops from invasive weeds. The 7-bar helps introduce the granular chemical into the soil just enough so that it can be evenly distributed throughout the field.

6. Mechanical Weed Removal

The 7-bar’s lightweight spring tines help manage weeds that start to thrive in your field after harvest. By damaging these weeds enough so they stop growing, your crops have less competition for nutrients in the soil.

.jpg) Spring Pressure Kit on the Riteway 7-Bar Harrow

Spring Pressure Kit on the Riteway 7-Bar Harrow

As you can see, there are many advantages to using a Riteway 7-bar harrow to prepare your fields for seeding and manage the crop residue after harvest.

Brad, Riteway Manufacturing, walks through the features on the 7-Bar Harrow

------

If you have any questions about our Riteway 7-Bar, Heavy, or Rotary Harrows, or any of our other tillage equipment, contact us or visit your nearest Flaman location.

Posted in Product Information | Tagged with Riteway harrow 7-bar heavy harrow tillage field prep seeding | More articles by Mitch Flaman

Maximize efficiency during your planting window with a seed tender from Flaman

Posted by Mitch Flaman Mar 24, 2022

Timing is everything. In the farming world, it is important to be ready to go when nature calls. Seed tenders are great tools to maximize efficiency and reduce downtime during the planting window. Similar to how grain carts keep the combines rolling at harvest time, seed tenders are designed to keep the drills in the field and maximize available seeding hours in the spring.

Some of the main reasons seed tenders are growing in popularity include:

- Speed & Efficiency

- Convenience, Versatility & Portability

- Scale Benefits

Speed & Efficiency

Speed and efficiency are often the deciding factors that influence producers to purchase a seed tender. By reducing downtime when filling and maximizing the available hours to plant, farmers will notice the immediate benefits of owning a seed tender. There are only 24 hours in a day, and when utilized properly, more work can get done in less time. Seed tenders are often able to load an air cart faster and safer than a stand-alone seed truck and traditional auger.

Convey-All CST-1550

Convenience, Versatility & Portability

Convenience, versatility, and portability are all key aspects to improving efficiency. Seed tenders give you the ability to load up seed in advance and strategically position your fill site where it needs to be. This can reduce the manpower needed to move seed around the countryside if your farmland is scattered. One person can independently use the onboard conveyor to conveniently load the drill with the ease of a remote, reducing the need for extra bodies to move around in trucks and start/stop the fill auger before it overflows the tank.

Scale Benefits

Scale systems allow producers to precisely meter products when filling and emptying the seed tender and when filling the air cart or planter. This ensures operators know exactly how much seed is being allocated to which compartment This also allows for even distribution when filling the air cart to ensure there is no excess product left in one tank and not the other.

Whatever your reason for wanting to improve efficiency, the time is now to visit your local Flaman dealer and learn how to maximize your planting window with a new seed tender.

-----

At Flaman, we offer three options of seed tenders in our product lineup – the Convey-All Commercial Seed Tender, Convey-All Seed Cart, and the Haul All Side Draw Seed Tender.

New to our product offering: Side Draw Seed Tenders from Haul All Industries

There are many different options and features to be aware of when considering a seed tender, including size, capacity, and functions. For more information on these three seed tenders options or to learn which one would best suit the needs of your operation, talk to one of our ag specialists at your nearest Flaman location.

Posted in Product Information | Tagged with seeding planting seed tender J&M Convey-All Haul All | More articles by Mitch Flaman

Heavy harrow meets high speed tillage: Why the Schulte SoilStar Disc Harrow is the best of both worlds

Posted by Mitch Flaman Jun 03, 2021

There are a lot of different discs and harrows on the market, but there is nothing quite like the Schulte SoilStar Disc Harrow.

Whether you are cleaning up after a bumper crop or dealing with pulse residue post-harvest, properly managing the trash in your field is important prior to seeding. The Schulte DHX combines a 5-bar heavy harrow and a double row of wavy coulter discs. This unique design is engineered to properly size straw and manage it in the top 1.5” – 2” of the soil.

Pictured above: 5-bar heavy harrow & wavy coulter discs

Although traditional discs can be effective at leveling a field, they are also known to bury heavy straw residue down into the soil and not properly size it. The result of this is that the field may look like it has been left clean, but the straw remains intact below the surface. The problems arise when the air seeder brings the straw back to the surface in spring and creates trash piles.

Harrowing can also prove effective in providing a finer finish to the field prior to seeding, but heavy trash that remains after a large-yielding crop can bunch up and create substantial piles of material behind the equipment.

Schulte 60' Disc Harrow in action

The Schulte Disc Harrow is the best of both worlds. The 18” double row of wavy coulter discs are spaced at 7.2” and are available in 8 wave and 13 wave options – effectively sizing the straw in the top 1.5” – 2” of the soil. This levels the soil without being overly aggressive and without over-disturbing the topsoil like a concave disc.

The coulter discs move independently from the main frame, which allows the operator to either maximize the weight of the machine on the cutting edge of the discs or lift them completely and use the DHX as a 5-bar harrow.

The Schulte SoilStar is available in 36’ and 60’ widths and requires a minimum of 8 HP per foot. Depending on the stubble and soil conditions, the DHX can be pulled between 7-10 mph.

DHX-600 (60' model)

DHX-360 (36' model)

DHX-360 (36' model)

Whether you are prepping the field in late fall or early spring, the Schulte DHX is proven to get you in the field sooner and maximize your time. With the ability to adjust the disc depth and tine angle from 35 degrees to 90 degrees, you no longer have to wait for ideal conditions to get rolling – the Schulte Disc Harrow is just as effective in wet conditions. When used in the springtime, the DHX can warm up the soil and speed up weed seed germination to promote a proper pre-seed burn off for producers hitting the field with a sprayer.

The versatility of the Schulte Disc Harrow is what sets it apart from the competition in the tillage world.

Reagan from Schulte Industries walks us through the features of the DHX-360

-----

For more information on how the Schulte DHX can help you manage post-harvest trash and straw residue in your field this fall or quicken soil warming and increase water penetration next spring, talk to one of our ag specialists at your nearest Flaman location.

Posted in Product Information | Tagged with Schulte DHX disc harrow soilstar 5-bar coulter discs | More articles by Mitch Flaman

From start to finish, the Flaman Grain Systems team is right beside you

Posted by Mitch Flaman Apr 07, 2021

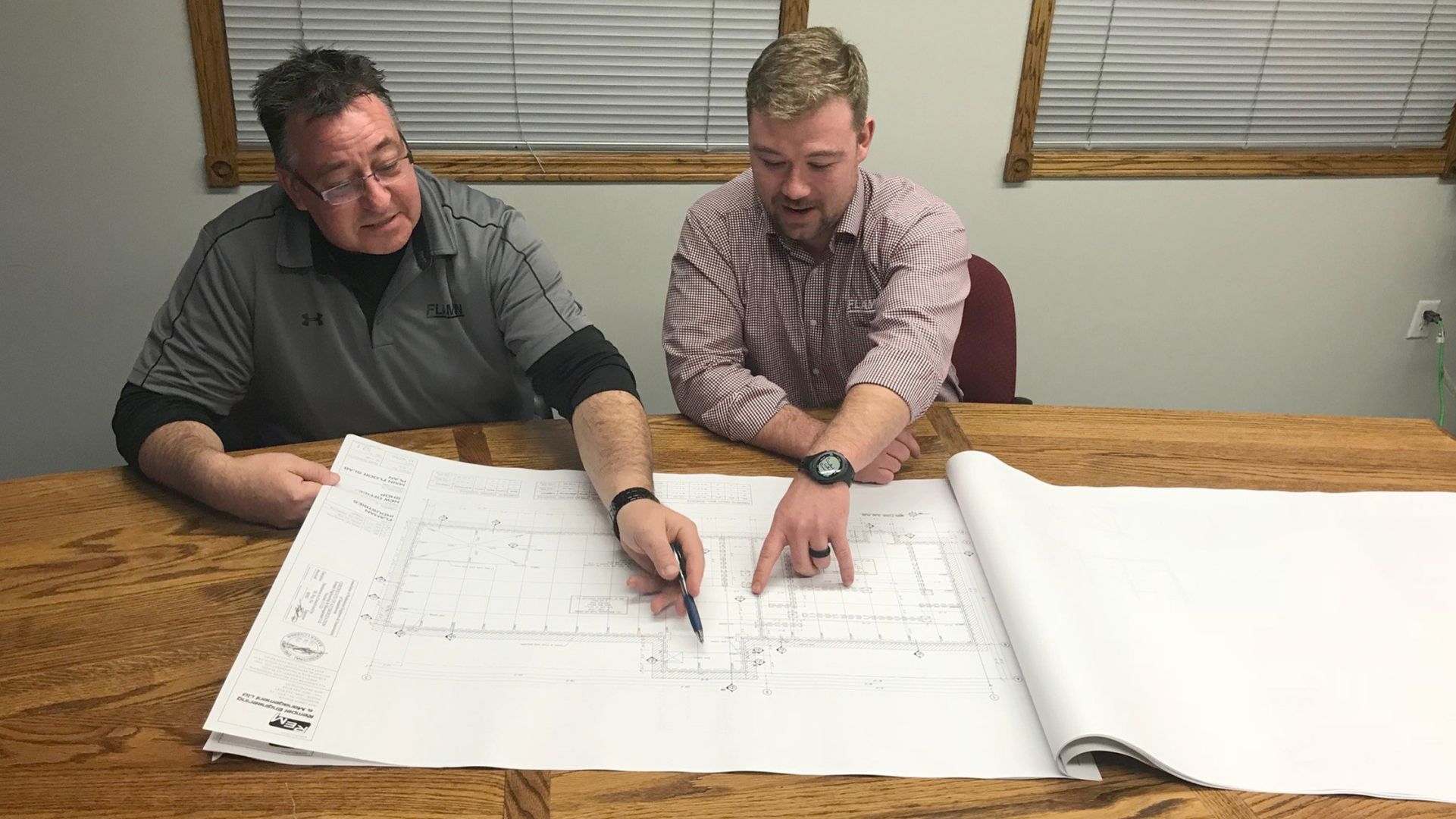

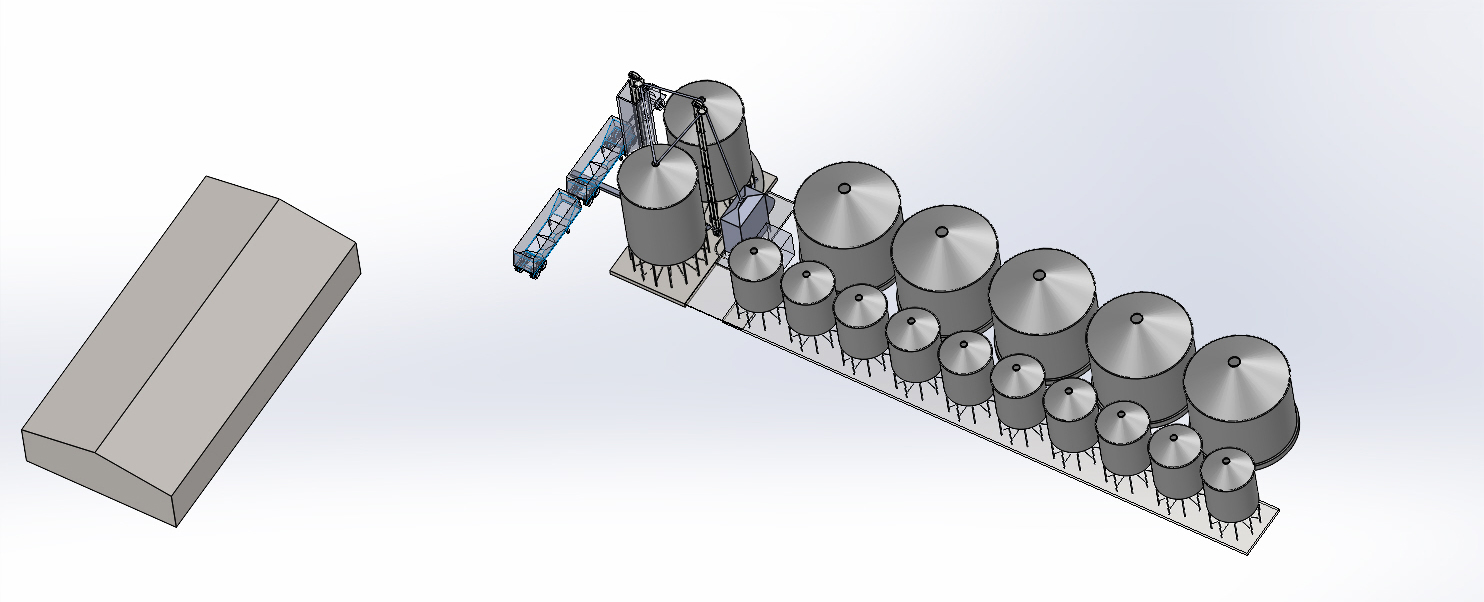

At Flaman, we understand that investing in your farming operation and expanding your yard site is important for continued growth and efficiency. That’s why we believe in supporting you from start to finish.

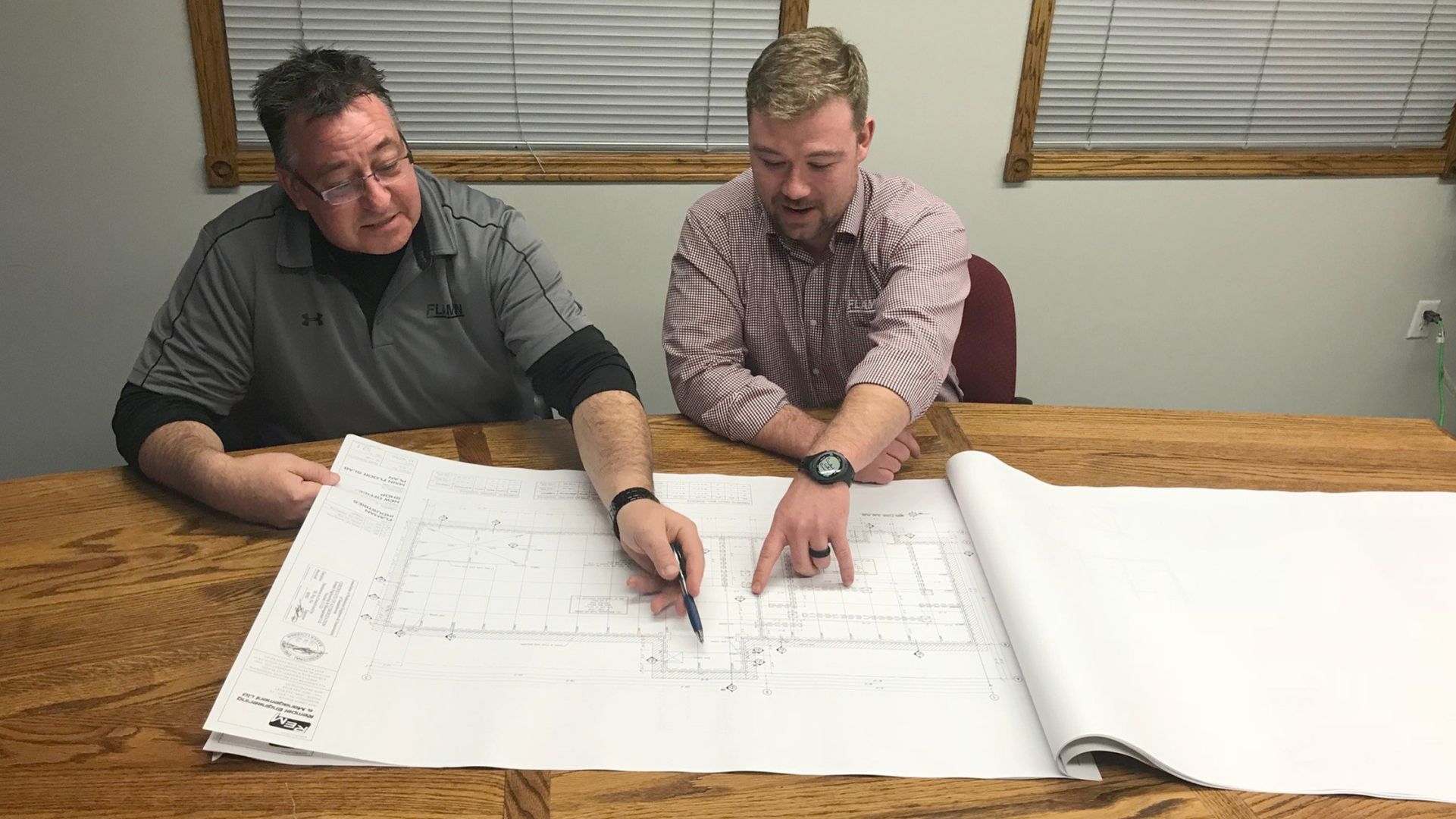

Customers share their experiences working with the Flaman team for their drying & handling setups (above)

Our Grain Systems team are experts in grain handling, grain drying, and grain cleaning. When you buy from us you are not just buying a product, you are gaining the ongoing support of a team with over 50 years of experience.

From Start to Finish

One of our industry experts will sit down with you to discuss and understand what your needs are for the coming year, as well as any future plans you may have. From there we will design a phased approach, with future expansion in mind.

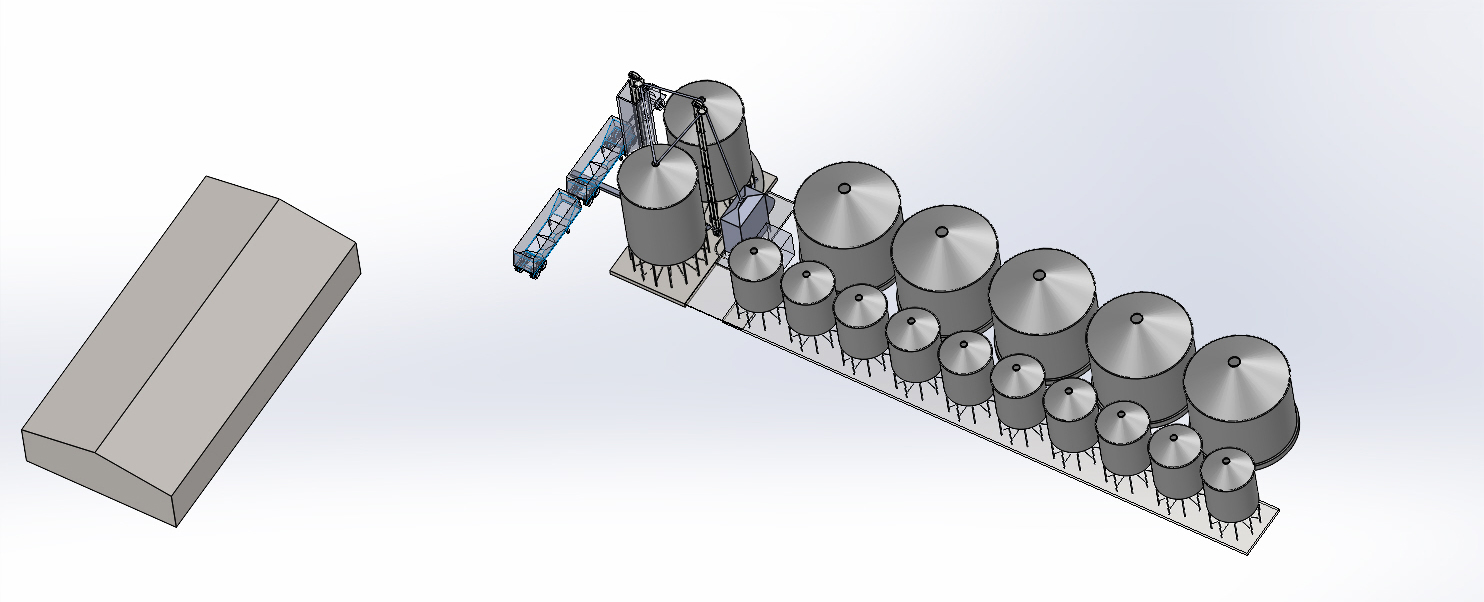

We provide complete engineered drawings constructed in-house, with multiple alternatives to come up with a solution that works for your operation.

Once the equipment is decided on, we will continue to work with you through the site preparation and construction. Our job is not done until your equipment is handling grain the way you expect it to. And even then, we don’t consider our job to be done. Rather, we shift our focus to make sure you remain satisfied with the performance of your equipment.

That’s where our Service Team comes in. This dedicated team of certified technicians specializes in after sales support including warranty, pre-season and post-season maintenance, optimization, and commissioning of your machines to ensure your equipment is always running at peak performance.

Our Service Team Lead explains what you can expect from our team even after the sale (above)

We also offer access to a customer service hotline with live tech support after hours (in season only).

When you buy from us you are not just buying the equipment, you are buying the total solution. We have been here for over 60 years and we look forward to continuing to grow with you as your farming operation grows.

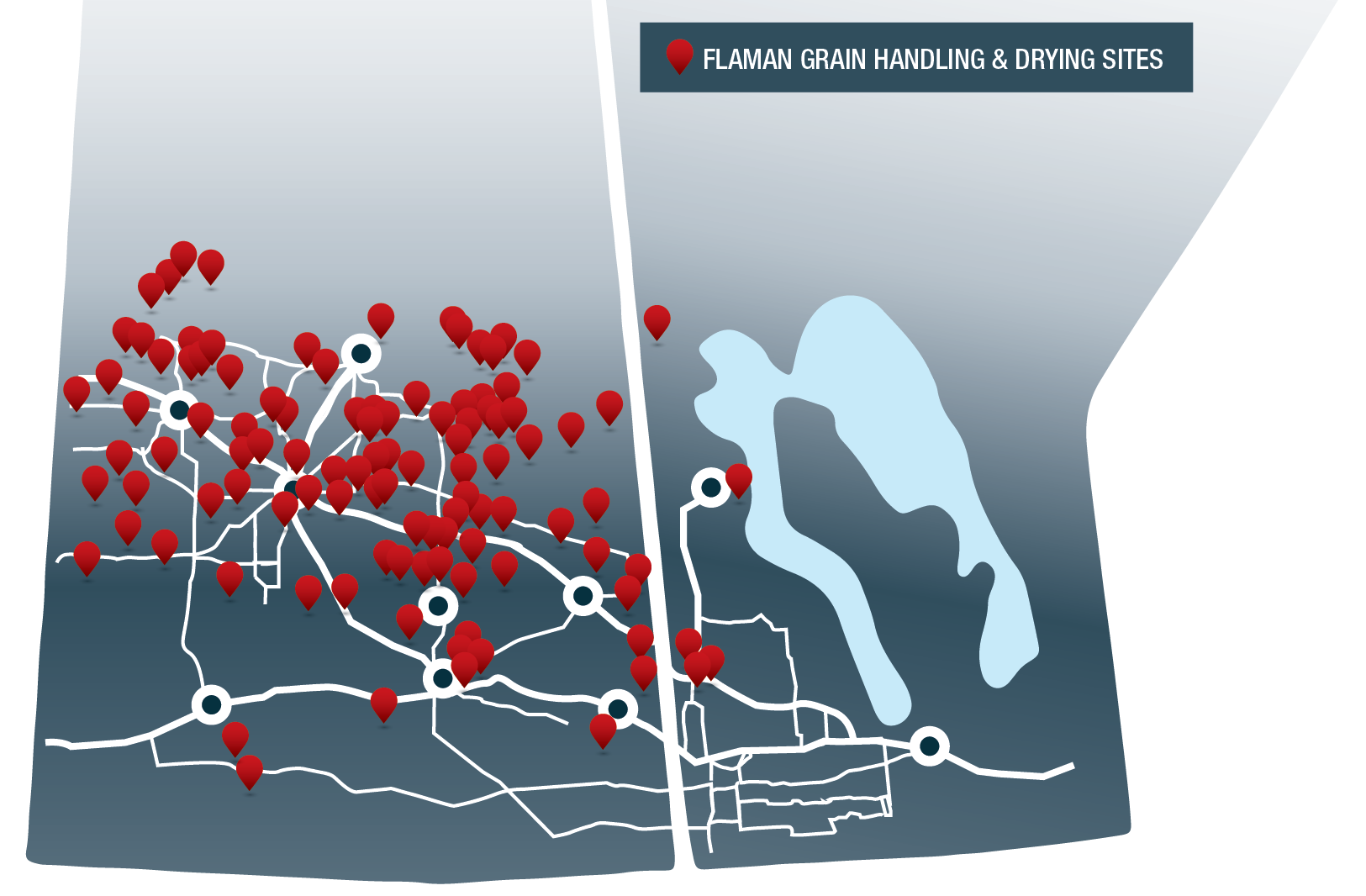

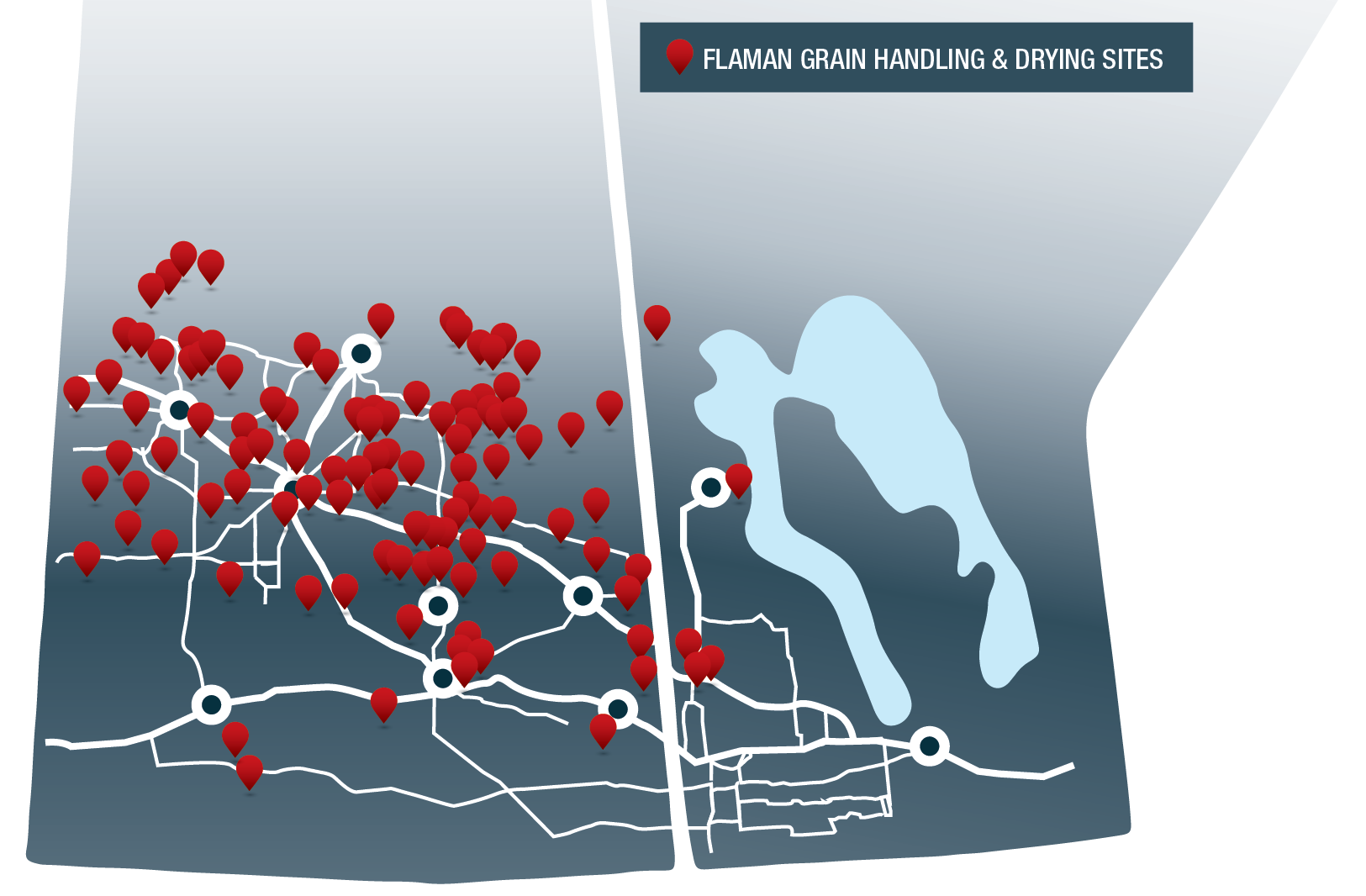

Map of Flaman Grain Handling and Drying sites throughout Saskatchewan & Manitoba (2021)

-----

If you are considering adding grain handling, drying, or cleaning equipment to your farm, give us a call or talk to one our Grain Systems specialists at your nearest Flaman location.

Posted in Division News | Tagged with grain systems grain handling grain drying grain cleaning optimization site drawings yard planning | More articles by Mitch Flaman

From start to finish, the Flaman Grain Systems team is right beside you

Posted by Mitch Flaman Apr 07, 2021

At Flaman, we understand that investing in your farming operation and expanding your yard site is important for continued growth and efficiency. That’s why we believe in supporting you from start to finish.

Customers share their experiences working with the Flaman team for their drying & handling setups

Our Grain Systems team are experts in grain handling, grain drying, and grain cleaning. When you buy from us you are not just buying a product, you are gaining the ongoing support of a team with over 50 years of experience.

From Start to Finish

One of our industry experts will sit down with you to discuss and understand what your needs are for the coming year, as well as any future plans you may have. From there we will design a phased approach, with future expansion in mind.

We provide complete engineered drawings constructed in-house, with multiple alternatives to come up with a solution that works for your operation.

Once the equipment is decided on, we will continue to work with you through the site preparation and construction. Our job is not done until your equipment is handling grain the way you expect it to. And even then, we don’t consider our job to be done. Rather, we shift our focus to make sure you remain satisfied with the performance of your equipment.

That’s where our Service Team comes in. This dedicated team of certified technicians specializes in after-sales support including warranty, pre-season and post-season maintenance, optimization, and commissioning of your machines to ensure your equipment is always running at peak performance.

Our Service Team Lead explains what you can expect from our team even after the sale

We also offer access to a customer service hotline with live tech support after hours (in season only).

When you buy from us you are not just buying the equipment, you are buying the total solution. We have been here for over 60 years and we look forward to continuing to grow with you as your farming operation grows.

Map of Flaman Grain Handling and Drying sites throughout Saskatchewan & Manitoba (2021)

-----

If you are considering adding grain handling, drying, or cleaning equipment to your farm, give us a call or talk to one our Grain Systems specialists at your nearest Flaman location.

Posted in Division News | Tagged with grain systems grain handling grain drying grain cleaning optimization site drawings yard planning | More articles by Mitch Flaman

Increase efficiency & reduce downtime during spraying this year

Posted by Mitch Flaman Mar 05, 2021

What started in the fall of 2020 as an idea to build an innovative sprayer trailer designed with functionality and convenience at the top of mind has resulted in the ST series of agriculture sprayer tender trailers from Flaman.

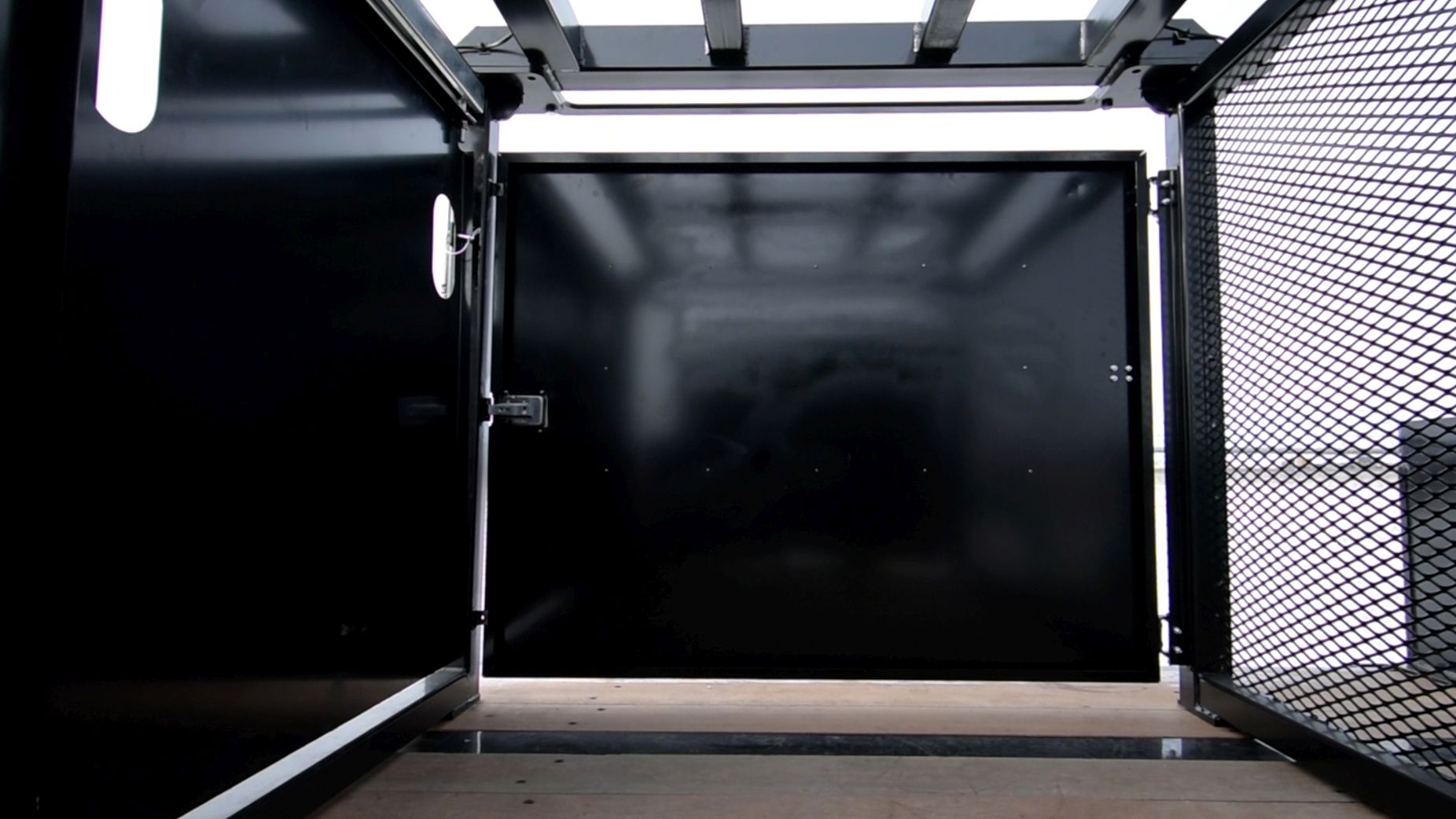

Model ST-9100

With safety, speed, and ease of use as the three pillars of design, these trailers were created to efficiently mix different batches of chemicals and quickly fill your sprayer – all with minimal downtime.

Now that all the planning and engineering has been completed, we are excited to have these units rolling through our production lines and hitting the market for the spring 2021 and 2022 seasons.

“We listened to our customers and put together all their best ideas into these all-new, all-encompassing sprayer tailers. Giving the customer all the features that they have always wanted to have – all in one unit. Flaman is proud to bring this product offering out to the marketplace just in time for the busy spring farming season.”

Bret Watson, Engineer

The Flaman ST-9100 and ST-9200 are tender-style trailers, built around a 53’ Behnke tri-axle trailer with a heavy-duty air ride suspension and 22.5” tires. They have an 80,000 lb GVWR, cross members on 12” centres, powder-coated paint, and Apitong hardwood decking. These trailers feature a 48” heavy-duty undermount toolbox for additional storage, mud flaps, and dual 2-speed jacks. The most notable difference of the ST-9100 and ST-9200 from other units on the market is the custom-designed 11’ upper kick compared to traditional 10’ upper kicks. This allows for a heavy-duty, low-profile 3,200 US gallon tank to clamp securely to the top deck with heavy-duty deck pins.

Chem Handler III

These ag sprayer trailers are completely outfitted with 3” hose and pipe for speed when filling and emptying the 4,500 US gallon (17,000L) tank on the back and the 3,200 US gallon (8300L) tank on the front. They are fastened directly to the trailer deck with heavy-duty steel mounting pins for safety instead of ratchet straps or chains. The entire system is controlled and mixed with a heavy-duty 3” Chem Handler III, a chemical handler that is fast, safe, and easy to use. The 3” steel piping is mounted under the trailer to keep the deck clean and eliminate the potential for tripping. The fill station is versatile and can feed either each tank individually or at the same time.

Features that make the ST-9100 and ST-9200 stand out include:

Stowable Fill Arm

The stowable fill arm has been engineered with 5” HSS tubing to manage the hose when filling the sprayer. This versatile fill arm takes care of the weight of the 3” hose when it’s full of product, and it swings out when filling the sprayer and easily folds back in when you are done. Your back will thank you!

The stowable stairs give safe and easy access to the deck when managing the Chem Handler III. In a matter of seconds, the safety pins can be pulled out and the stairs can be folded down – no more hopping up and down from the deck like you are training for a Spartan Race! The textured grate steps provide additional traction and reduce the potential for unnecessary slips and falls.

The tote storage is loaded with innovative features and has been engineered to safely store two chemical totes on top with secure ratchet strap tie-downs. It is easily accessible from both sides of the trailer, as well as from on top of the deck. It can be used to store extra fuel, additional hose and couplings, chemical jugs and treatments, tools, extra parts or sprayer nozzles, and safety equipment. It has strategically been offset towards the passenger side of the trailer to allow for additional walking room on the driver side and access the upper kick with an integrated safety handrail.

Both tanks have built-in sight tubes for easy water level readings.

LED Light Kit

The trailer comes standard with four LED lights to increase safety and reduce the chances of an accident after the sun goes down. There is a convenient light switch located on the passenger side of the tote cage and in easy reach from the ground or deck. All wires are run inside of the frame and are powered by the 7-pin trailer plug.

The ST-9200 includes an additional 1680-gallon (6400L) Chembine Hot Tank. Designed to reduce wait times and increase efficiency, the Hot Tank can mix and agitate the next batch of treatment while the sprayer is out in the field. When the sprayer is ready for another fill, the Hot Tank can quickly unload the next batch of chemicals that have already been already prepared. This feature can be added to any ST-9100.

-----

For more information on the Flaman ST Series Sprayer Trailers, talk to one our ag & trailer specialists at your nearest Flaman location.

Posted in New Products | Tagged with spraying sprayer trailer ag trailer Flaman ST-9100 ST-9200 | More articles by Mitch Flaman

When the elevator calls on a cold day, will your auger be ready? Take these tips for a dependable cold weather start

Posted by Mitch Flaman Feb 11, 2021

With the cold weather snap we've been having, I'm reminded that my dad always said, "Things just start breaking down and don't work well after -25". That being said, you don't always have the luxury of taking a day off when the elevator calls for grain in the middle of winter. In case you're in a rush and it's too cold to fire up the auger to load the trucks, take a few minutes and remind yourself of a couple of key tips to ensure that your auger or conveyor starts when you need it to..jpg)

Fuel

Fuel problems always seem to show up when the cold hits. The two most common fuel problems are:

1. Old/dirty fuel

2. Water in the fuel

Make sure you are always using good clean fuel. Check your fuel filters often, and replace them when necessary. It's the easiest way to ensure the auger engine will start easy and run clean at a cold, crucial time. The last thing you want when you're in a rush is pausing to clean the carb or rip the engine apart. If you're not sure how old the fuel is in the jerry can you're about to use, you're better off using it for a bonfire. Go get some new stuff and prevent the headache.

Water in fuel is as bad as dirty or old fuel, and sometimes worse. Because water is heavier than fuel, it will usually find its way to the bottom of the tank, often where the fuel line feeds the carburetor. And you can be sure that it will either freeze up when it's cold or prevent the motor from igniting when you need it to most. If there is a drain valve on your auger, it is recommended you periodically drain the fuel in the spring or when the unit is warmed up in the shop. Fuel additives such as Sea Foam or isopropyl-based gas line antifreeze can also help mitigate the problems old or water-based fuel can pose on engines.

EFI vs Carbureted EnginesMost farms have augers or conveyors with both carbureted and EFI (electronic fuel injection) motors. Although they operate very much the same, the starting procedure may differ.

On a carbureted engine, add a small amount of throttle to ensure the engine will idle, pull the choke fully out and start to crank the motor over. Be sure not to over-throttle and flood the engine. Once the motor fires and runs for a few seconds, you can usually push the choke in half-way and let the engine warm-up for 5-15 minutes. After the engine is good and warm, you can push the choke in all the way and you should be good to go.

When cold starting an EFI engine, there are a couple other things to consider. Set the throttle to approximately one-third open (between idle and one-half throttle), turn the key on, and watch for any lights on the control panels. This will ensure everything is powering up. Listen for a humming sound to confirm the electric fuel pump is working. After the pump kicks in, fully turn the key to the start position and start cranking the engine over. If it stalls or does not start after a few seconds, cycle the key to the off position, and repeat this step. Wait for the electric pump to kick in again and start cranking the engine over. This may need to be repeated multiple times. Once the engine is idling and running, allow 5-15 minutes for it to warm up before putting any load on it.

Following the tips above will ensure you the best chance of making sure your auger/conveyor starts in the cold weather. Sometimes it is just too cold for an engine to start regardless of what prep work you do. In that case, it might be time to go inside where it's warm, and browse for a new auger with modern technology and new, clean fuel in the tank!

-----

For more information on our grain handling equipment, auger accessories, or to learn more about cold starting an engine, talk to one of our agriculture specialists at your nearest Flaman location.

Posted in Product Information | Tagged with auger conveyor engine EFI carburetor cold start | More articles by Mitch Flaman

After 50 years, Kello-Bilt discs remain innovative, family-manufactured, and built to stand up

Posted by Mitch Flaman Feb 03, 2021

When buying a field disc, you need the confidence to know that it is going to work the way you expect when you need it and not break down, leaving you stranded with work to be done. This is why Flaman chose to team up with Kello-Bilt products over 40 years ago. Like Flaman, Kello-Bilt remains a family-owned business that keeps quality and reputation top of mind. A field disc is meant to be put through tough conditions. Continued innovation is what has kept Kello-Bilt tillage equipment ahead of the curve and outlasting its competitors.

Kello-Bilt Tandem Disc - Model 225TSW

For over 50 years, Kello-Bilt discs have been Canadian-made to “be better”. They’re built heavy and designed to last in the toughest conditions. The company has continued to evolve with experience and improve the things that “didn’t work” or simply didn’t stand up to other discs in the tough Canadian environment. This is how the idea for the self-lubricating oil-bath bearing was born. The self-lubricating oil-bath bearing proved to be superior to traditional greaseable ball bearings.

Today, regardless of price, Kello-Bilt discs are still manufactured to the highest standard with Canadian and North American steel. They are constructed with high-strength steel tubing, heavy gussets, and powder-coated components to ensure best-in-class quality and performance. This ensures the longevity of your purchase for years to come. The oil-bath bearings and boron steel blades are designed and sourced from Brazil and Argentina specifically for Kello-Bilt. Boron steel blades are less brittle than traditional carbon steel blades.

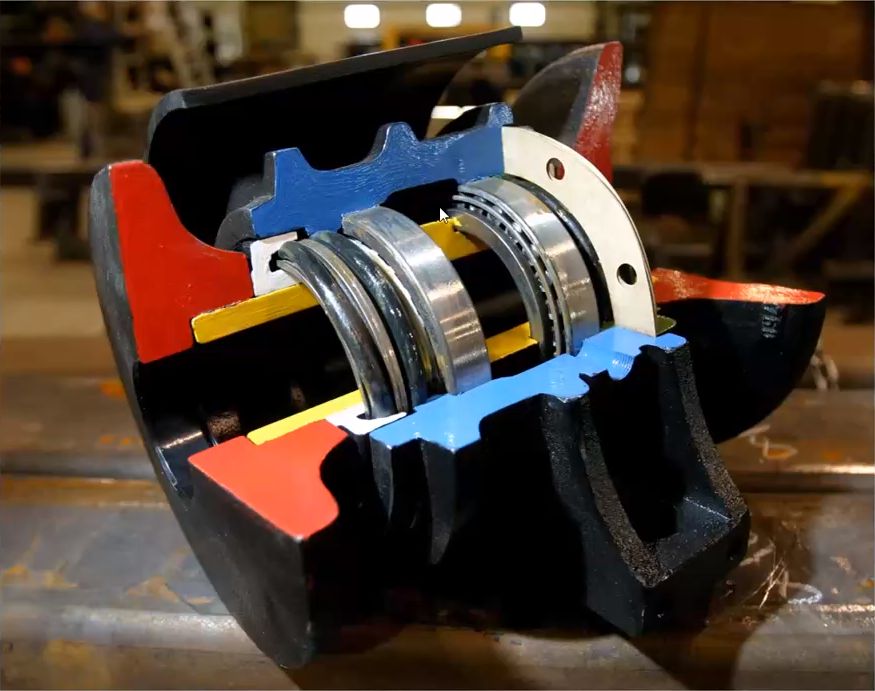

Oil-Bath Bearing Interior

Oil-Bath Bearing InteriorThe oil-bath bearing uses two tapered roller bearings mounted in a cast housing. The dual-cone seal constantly lubricates the bearing. They sit on the interior axle, which is never in contact with the actual gang shaft. Tapered roller bearings are ideal for a disc application because they are designed for side thrust. Most of the pressure a disc blade faces is side pressure, NOT radial pressure. Ball bearings are designed for radial pressure. Oil-bath bearings are extremely low maintenance. Testimonials show Kello-Bilt discs from the 1980s are still operating with their original bearings after over five or more sets of replacement blades. The beauty of the oil-bath bearing is that they’re rebuildable. As long as you make sure not to run the blades too loose, as it will put pressure on the housing and cause leakage, the bearings can last for decades.

Kello-Bilt Offset Disc - Model 275

If you’re serious about purchasing a quality field disc, contact your local Flaman dealer today. A Kello-Bilt disc with oil-bath bearings might be as serious as you are.

Posted in New Products | Tagged with Kello-Bilt disc field disc tillage | More articles by Mitch Flaman

Three reasons the Batco BCX3 needs to be your next conveyor

Posted by Mitch Flaman Jan 21, 2021

It’s here. The legendary orange “gentle giant” from AGI/Batco has received more than a facelift for 2021. After a complete redesign from hopper to downspout, the BCX3 conveyor has a few new features worth bragging about. Aside from the redesigned S-Drive, new Turbo-Clean Wash System, and remodeled fuel tank, there are still 3 big upgrades that make this the most versatile conveyor yet.

- Move All Commodities - Most notably, the biggest feature of 2021 is the BCX3 conveyor’s ability to move all farm commodities - that’s right, INCLUDING CANOLA. Gentle on pulses, quick on cereals, and capable of oilseeds, you now have one tool for all your jobs. This has been made possible with a redesigned hopper & downspout, plus the new Turbo-Clean wash system with multiple scrapers & brushes. As with the use of any oilseed, additional maintenance and cleaning is required to ensure the longevity of your conveyor.

- Multiple Controls, One Location - Redesigned, with functionality and safety in mind, you will find all the controls in one location. This means you can adjust the throttle, engage the clutch, change the height for both hopper & discharge, and drive all from one spot. No more reaching. The conveyor’s control center has been relocated to provide better ergonomics and visibility as you drive, as well as additional clearance when setting up underneath your hopper.

Ergonomic Command Centre

- Move with Ease - A completely redesigned mover adds substantial traction and maneuverability for your conveyor. The new all-terrain tire design has been coupled with an internal braking system to prevent rollback. The drop-and-go design is simple and safe - no more engaging or locking hubs. The drive wheel has been relocated to better utilize the weight distribution of the conveyor. This adds strength and exceptional traction. Did we mention the increased turning radius? The new mover design offers unparalleled maneuverability and versatility.

Redesigned Mover Kit

You need to see it to believe it.

For more information on our AGI Batco BCX3 conveyors, talk to one of our ag specialists at your nearest Flaman location or give us a visit and we would be happy to show you what all the buzz is about! We may even let you take it for a spin. Even with winter conditions, we can assure you that you won’t need to worry about getting it stuck!

Posted in New Products | Tagged with conveyor Batco BCX3 grain handling | More articles by Mitch Flaman

Locations

Locations