Flaman Rentals Blog

RSS feed

Categories

Recent activity

- What's it like being a Flaman Rental Dealer?

- A Brief History of the Newest Flaman Store in Swift Current

- Disney's NEW Leadership Excellence Training Course

- Disney's Approach To Quality Service

- Disney's Approach To Quality Service

- Trailering 'Rules of the Road' Updated

- 10th Annual Frank J. Flaman Foundation Gala 2016

- Why Frank Cares

Authors

Archive

Hitting the Road: Which Sled Trailer is Right for You?

Posted by Paul Boechler Dec 01, 2020

Hitting the Road: Which Sled Trailer is Right for You?

The winter of 2020/2021 is shaping up to be a great year for sledding. A huge dump of snow across much of the prairies in early November coupled with a global pandemic keeping people at home is the perfect recipe for spending quality time on some fresh powder.

There’s a lot that goes into buying a snowmobile trailer. We’ve talked about it before, but some of the big considerations include choosing between an open vs. enclosed trailer, steel vs. aluminum frame and heated vs. not. A lot of your decision-making will likely come down to budget, storage requirements, your vehicle’s towing capacity and where/how much you’ll use the trailer. If you’re looking for customization, our parts & service team can help you upgrade your trailer to fit your lifestyle.

Enclosed Sled Trailers

Inline:

Inline enclosed sled trailers are great for people with half-ton trucks who want to haul 3 sleds (or 2 sled with some extra storage). By parking one sled via the front ramp door and two in the main ramp, a 7’ or 7.5’ width inline is an ideal design for smaller trucks.Deck over/Highboy:

The deck over (aka highboy) is the perfect trailer for the serious sledder. Available in 8’ or 8.5’ width models, they’re designed to easily fit up to 4 sleds in, with heated and insulated models available. Keep in mind trailers this big typically require a ¾- or 1-ton truck to haul. They’re also built with higher clearance so you’re able to pull them in rough terrain or snowy conditions.Lowboy:

The lowboy toy or car hauler is designed with a lower deck with the clearance to fit a car, side-by-side (UTV) and other toys. Typically, these trailers are 8.5’ to accommodate space requirements. They’re also ideal for pulling sleds with a long track & skis, making it ideal for pulling mountains-ready sleds.Open Sled Trailers:

Open deck sled trailers are much more economical than their enclosed counterparts. The argument of steel vs. aluminum frame comes into play here. Aluminum is lightweight while maintaining similar towing capacity and increased longevity, as it doesn’t rust or weather as quickly. However, if you’re looking for versatility beyond hauling snowmobiles or ATVs, steel is more economical as they typically cost less than an aluminum trailer would.Winter Staycation Contest:

If you previously weren’t aware, we’re giving away some awesome trailer accessories to make your sledding experience even better this winter. Things like tie downs, explorer sleds and wheel locks are up for grabs simply by liking our Facebook or Twitter page, liking the posts and tagging a friend. Our Winter Staycation contest is on now until mid-January, 2021. Visit our social pages for more information!Posted in Trailer Tips | Tagged with sled trailers trailer comparison | More articles by Paul Boechler

Move your grain with the all-new AGI Hutchinson Double Run Chain Conveyor

Posted by Paul Boechler Sep 14, 2020

The AGI Hutchinson Double Run Chain Conveyor is a brand new product to the Flaman lineup. It is built in Western Canada with the prairie farmer in mind. Manufactured at AGI’s plant in Swift Current, SK, it is designed to handle delicate crops grown on the prairies, like pulses, far more gently than an auger would.

The UHMW plastic paddles gently convey grain

Maneuverable in Tight Spaces:

Modeled after the clean grain elevator on your combine, its UHMW plastic paddles convey crops to your bin in a gentle manner. A huge benefit of this is the ability to operate at full capacity from nearly any angle, fitting into tighter spaces.

Another feature of the Double Run is the easy to use swivel arc kit, which makes the unit highly portable around the yard. You can move it from bin to bin or dryer, by simply swapping a few pins.

The swivel arc kit allows for easy maneuverability

Low Power Requirements:

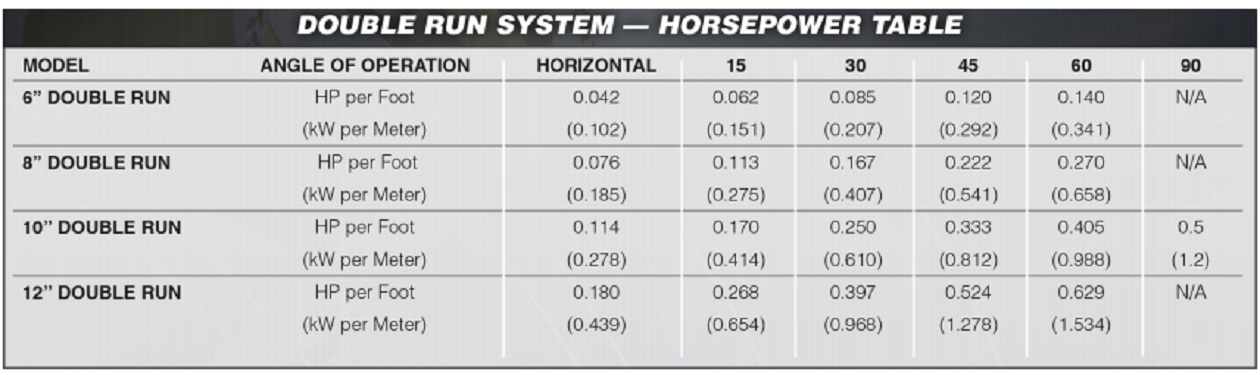

While the Double Run is powerful in getting your grain into the bin, it has a low horsepower requirement compared to alternative grain handling equipment. As an example, 8” model with a length of 82’ requires just 18 HP at a 45° angle (see chart below). These units are available with an electric motor or PTO drive, giving you plenty of power options.

Proven Reliability & Longevity:

We all know an unreliable auger can be a huge problem for your operation at harvest time. The Double Run was designed as a solution to this problem. The chain conveyor requires less maintenance and has more longevity than your typical auger. Keep the chain running straight and tensioned properly, and these units will just run. And run. And run.

Travis Frey of AGI walks us through exactly what makes this unit different:

The Double run comes in lengths of up to 82’ on the 8” and 10” models, with up to 4,000 BPH capacity on the 8” and 6,000 BPH on the 10”. It is also available in a 12” model, which has a 10,000 BPH capacity and lengths up to 130’.

Stop by your local Flaman Ag store or give us a call for more information on this unit.

Posted in New Products | Tagged with AGI Hutchinson Double Run chain conveyor grain handling grain systems Flaman | More articles by Paul Boechler

Harvest 2019: An unconventional way to dry your grain in wet conditions

Posted by Paul Boechler Oct 09, 2019

The 2019 harvest is shaping up to be frustrating for most. It’s no secret that harvest is well behind this year, with only 34% of crops being combined in Alberta (47% 3-yr avg), 47% in Saskatchewan (75% 3-yr avg), and 71% in Manitoba (85% 3-yr avg) as of last week. Wet weather has plagued the prairies, with record rainfall in Manitoba and snowfall in southern Alberta & Saskatchewan in September. A combination of high moisture levels and widespread crop damage has contributed to diminished grade.

It’s now a race to get remaining crops off the field and although we can’t control the weather, we can help you maintain the grade of your grain by getting it dried faster and limiting spoilage. The most effective option is a NECO dryer from Flaman, which can be scaled to the size of your operation. However, dryer installs are contingent on many environmental and logistical factors and it’s far from a guarantee that a dryer purchased today would be installed before the end of harvest.

So, what does a farmer do if he or she can’t get a dryer installed in time?

Our team in Saskatchewan has heard a lot of stories from our customers who’ve resorted to unconventional methods to dry their grain. The overwhelming favourite by local farmers has been the Frost Fighter (available only at our Saskatchewan locations), which is a diesel-powered 350,000 BTU industrial heater designed to heat remote construction sites and shops. As it turns out, they are also easily adaptable to a bin aeration system and can pump heat into two bins simultaneously. It’s been a lifeline given the soggy conditions.

Kelly Stewart, the operations manager at our Flaman Moosomin location, was the man who made this idea a reality:

“I saw a video a couple years ago of an Alberta farmer using a similar method and he claimed it worked like a charm. It inspired me to try it out given how wet it’s been this year. Some local farmers put it to work and were extremely pleased with the results. It’s not a perfect solution and we know it’s not recommended by the manufacturers, but desperate times have forced us to think outside the box.

With a little extra work, moving your grain around and monitoring your moisture levels closely, we’ve heard from many happy customers that have seen up to 30,000 BU dried in a week. Obviously, the best way to dry your grain is with a dryer but given how wet it’s been and with more precipitation in the forecast, this has been a great makeshift way to salvage what has been a tough harvest.”

Interested in learning more about grain drying? Talk to one of our agriculture specialists at your nearest Flaman location.

Posted in Ag news | Tagged with grain drying frost fighter neco dryer flaman harvest crops aeration | More articles by Paul Boechler

NECO Grain Dryer Build

Posted by Paul Boechler Jun 12, 2019

We recently had the opportunity to build the largest private NECO grain dryer in Western Canada – a NECO Mixed Flow 6 Burner D24380 -- for a large farming operation outside of Edmonton, AB. It was a complex endeavour with many moving parts, and it required many hours of planning to execute..jpg)

We had help from several outside sources: Freeway Transport, who were responsible for the dryer delivery; Xcaliber Crane & Rigging who handled the hoisting of the dryer; and Continental Bins, who provided assembly services. Additionally, Ron Kleuskens from NECO supervised the build and many members of the Flaman Nisku team assisted throughout the day where they were needed. And most importantly, the 4 owners of the farm and their sons, daughters, grandchildren & significant others were all present at one time or another throughout the day. They were the real supervisors!

.jpg)

Build Day was kicked off with the delivery of the dryer. This consisted of 7 truckloads originating in Omaha, Nebraska. Each delivery was staggered by 2 hours, which allowed enough time for our crane and assembly teams to position and install each section before the next was delivered.

.jpg)

With the help of our partners and employees – more than 20 people in total -- we were able to install this behemoth of a dryer in one jampacked, 10 hour day.

.jpg)

The dryer will serve as a flagship operation in the area and will likely create business not only for our customer’s farm, but others in the area as well. It’ll be an economic driver in the area for many years to come. We're thankful to be a part of this project and meet the needs of our customer. Customer service is one of the core beliefs Flaman was founded on and it’s why we’re celebrating 60 years in the agriculture industry in Western Canada.

Posted in Ag news | Tagged with grain dryer farming neco flaman install | More articles by Paul Boechler

Locations

Locations